In the food industry, controlling a clean environment and preventing mold is a mandatory requirement. VCR supplies cleanroom lights that resist mold and dampness in compliance with HACCP, GMP, ISO 22000 standards, offering stable illumination, inhibiting microbial growth, and ensuring safety in food production processes.

- 1. Why does the food industry need cleanroom lights resistant to mold and dampness?

- 2. Criteria for selecting mold-resistant cleanroom lights for food factories

- 3. Common types of cleanroom lights used in the food industry

- 4. Reputable supplier of cleanroom lights for the food industry – VCR

- 5. Process for selecting and installing cleanroom lights at VCR

- 6. Frequently Asked Questions (FAQ)

1. Why does the food industry need cleanroom lights resistant to mold and dampness?

In the food sector, production environments always carry the risk of microbial growth, especially mold. This factor not only compromises food safety but also directly impacts product quality and brand reputation. One of the main causes is an inadequate lighting system that fails to meet cleanroom standards, allowing humidity to accumulate and bacteria to grow.

Cleanroom lighting – not just ordinary fixtures

Unlike standard lights, mold-resistant cleanroom lights are specially designed for high hygiene areas such as food processing plants, packaging rooms, storage areas, etc. These lights perform two essential roles:

-

Provide stable illumination with accurate color rendering to support the quality control of raw materials and finished products.

-

Prevent microbial growth via a sealed design, moisture-resistant casing, easy-to-clean surfaces, and minimizing dust or bacterial accumulation.

Meeting international requirements

Food safety standards such as HACCP, GMP, ISO 22000 specify clear requirements for lighting systems in processing areas:

-

No water condensation or light leakage.

-

Lighting materials must be corrosion-resistant, easy to clean, and must not cause cross-contamination.

-

Illumination intensity and quality must allow staff to perform precise tasks.

Therefore, investing in a compliant cleanroom lighting system not only helps prevent mold and microbes but is essential for food factories to pass inspections from clients and regulatory authorities.

Read more: Latest Price List for Cleanroom Lights Used in Food Processing Plants

2. Criteria for selecting mold-resistant cleanroom lights for food factories

Choosing the right cleanroom light is key to ensuring a sterile, dry, and standard-compliant production environment. Below are important criteria to consider when investing in a lighting system for food factories:

IP65 or higher rating – waterproof and dustproof

In food processing, moisture and humidity are always present. A cleanroom light with IP65 or higher:

- Prevents water ingress into internal components.

- Resists dust accumulation that degrades performance or hygiene.

- Ensures stable operation even under wet cleaning conditions.

Corrosion-resistant and easy-to-clean materials

Lighting fixtures used in the food industry should be made of anodized aluminum, stainless steel, or high-grade technical plastics with characteristics such as:

- Resistance to chemicals used in cleaning.

- Smooth, seamless surfaces that are easy to clean and do not harbor bacteria.

- No risk of rust or shedding particles that could contaminate food.

High Color Rendering Index (CRI) – accurate color perception

CRI indicates how accurately colors are rendered under the light. In the food sector:

- A minimum CRI ≥ 80 is recommended so staff can easily distinguish material colors, spot spoilage, or discoloration.

- Accurate lighting supports precise inspection in meat, vegetables, or packaged product evaluation.

LED lighting – low heat and energy saving

- LEDs do not generate excess heat → they do not raise the room temperature, which helps limit microbial growth.

- Can save 50–70% of power compared to traditional fluorescent lamps.

- Long lifetime and lower maintenance needs reduce disruptions in production.

Prefer antibacterial technologies (if available)

Modern LED models may integrate features such as:

- Silver ion coatings to inhibit bacterial adhesion on the surface.

- Dust-resistant and anti-static properties to reduce microbial growth.

Such features are ideal for food factories with high hygiene demands, particularly those producing fresh or ready-to-eat products.

Read more: UV-C Lighting in Food Production Clean Rooms: Benefits and Best Practices

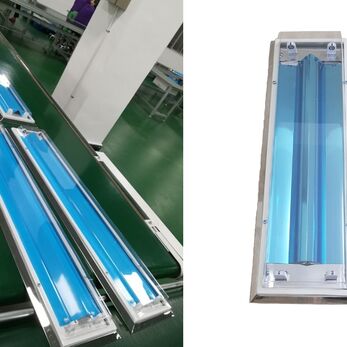

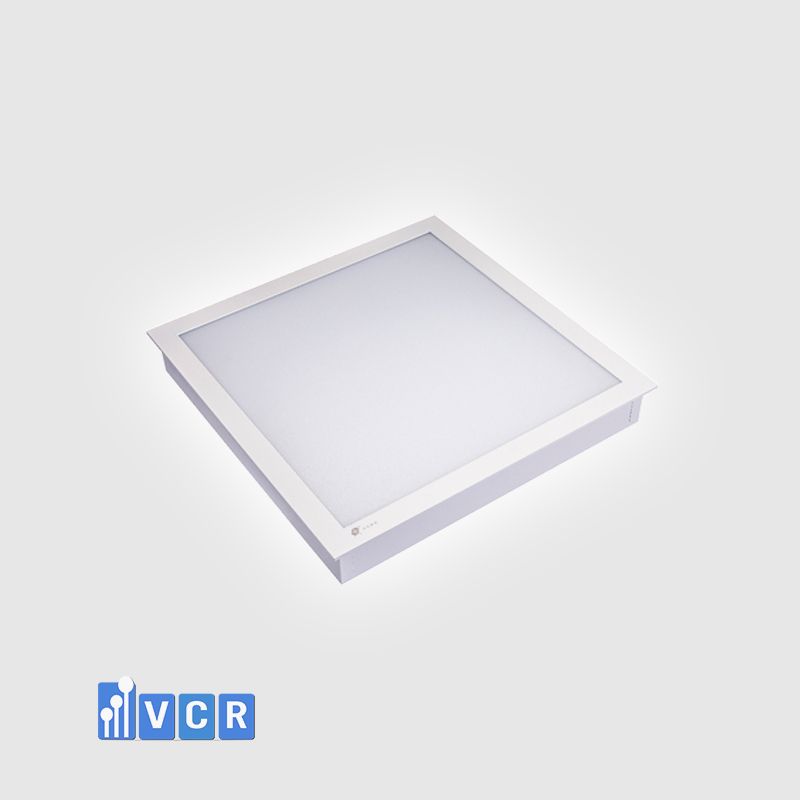

3. Common types of cleanroom lights used in the food industry

Depending on the area within a food factory, businesses should choose lighting types that suit environmental conditions, hygiene standards, and usage. Below are three common types currently used:

| Light Type | Main Application | Key Advantages |

|---|---|---|

| LED panel lights | Packaging rooms, QC inspection areas | Even light distribution, no glare, high CRI, energy efficient, long lifespan |

| IP65 moisture-resistant lights | Wet processing zones, raw material washing | Waterproof, dustproof, sealed casing without condensation, compliant with HACCP/GMP |

| Explosion-proof lights | Cold storage, areas with volatile chemicals | Safe for hazardous zones, spark-proof housing, withstand high temperature, meets ATEX standards |

Suggested use by zone:

-

For raw/material washing and high humidity zones: use IP65 or higher.

-

For dry packaging and inspection rooms: LED panels are ideal to ensure soft, clear lighting for product checking.

-

For cold storage or chemical zones: explosion-proof lighting is required for safety.

Choosing the correct type of cleanroom lighting for food industry not only boosts lighting efficiency but helps meet stringent food hygiene regulations, reduce microbial risk, and avoid technical failures.

Read more: 5 Basic things about clean room lights that you need to know

4. Reputable supplier of cleanroom lights for the food industry – VCR

When it comes to cleanroom lighting solutions for food factories, VCR is a leading and trusted provider chosen by many businesses due to its expertise and over 10 years of experience in the cleanroom equipment field.

Over 10 years serving the food sector

VCR has partnered with numerous food factories—both domestic and FDI (foreign direct investment) enterprises—nationwide. They understand the technical requirements in food processing: mold resistance, dust control, microbial prevention, and energy efficiency.

Consulting solutions compliant with GMP, ISO 22000

Beyond supplying lights, VCR offers a full lighting design consultation service that ensures adherence to strict standards such as GMP, HACCP, ISO 22000. They coordinate with factory technical teams to propose suitable lighting plans for areas from raw processing to packaging, cold storage, and QC.

Well-stocked warehouse – sample availability

VCR distributes various LED panel models, IP65 moisture-resistant lights, and explosion-proof units from quality brands, all tested before shipment. Additional benefits:

-

Samples are available for customer evaluation.

-

Customization options for lighting levels or dimensions suited to the cleanroom design.

Warranty & nationwide delivery

-

Warranty periods range from 12 to 36 months depending on the product line.

-

Flexible logistics and fast delivery, especially in Ho Chi Minh City, Hanoi, and major industrial zones.

-

Technical support and installation guidance are provided remotely or in person as needed.

With VCR, clients receive not only products, but comprehensive cleanroom lighting solutions — safe, compliant, and certified.

Read more: What is Requirements for clean room lighting?

5. Process for selecting and installing cleanroom lights at VCR

To ensure the lighting system not only meets standards but suits each zone in a food factory, VCR uses a clear, professional, and flexible 4-step process:

Free on-site survey

- VCR’s technical team visits the factory to assess current conditions: area size, humidity, ceiling type, production zones, etc.

- Identify factors impacting lighting performance like steam, dust, zones requiring high or low illumination.

- Survey is free and does not obligate orders.

Propose optimal lighting solution

- Based on the survey, VCR recommends suitable lighting for each area (processing, packaging, cold storage, etc.).

- Provide a layout sketch or lighting plan, with calculations for wattage, quantities, and positions.

- Ensure compliance with GMP, HACCP, ISO 22000 standards.

Provide equipment & installation guidance

- Deliver fixtures on schedule after quality inspection.

- Provide detailed installation instructions.

For full turnkey projects, VCR can coordinate partner installation teams to save time for customers.

After-sales service & periodic inspection

- Warranty: 12–36 months depending on model.

- Provide periodic maintenance and checks on schedule per customer.

- Maintain spare part stock for quick maintenance when needed.

VCR supports the client from survey to operation, so companies can invest in cleanroom lighting confidently for their food factories.

Read more: 8 Crucial Factors to Ponder Before Buying Cleanroom Lights

6. Frequently Asked Questions (FAQ)

Q: Is cleanroom lighting mandatory for food factories?

A: Yes. If the factory operates under standards such as GMP, HACCP, or ISO 22000, the lighting system must satisfy requirements of hygiene, dust control, cross-contamination prevention, and stable illumination. Using cleanroom lights is part of the environmental control system required.

Q: Which light type is suitable for high-moisture areas like raw ingredient processing?

A: Use lights rated IP65 or above. These have sealed housing resistant to water and dust, often made of anodized aluminum or stainless steel to minimize corrosion and ease cleaning — ideal for areas like vegetable/fruit washing and raw material processing with high humidity and bacterial risk.

Q: Does VCR support installation of cleanroom lighting?

A: Yes. VCR offers full lighting solutions including:

-

On-site survey

-

Solution consultation per GMP

-

Detailed installation guidance

-

Connections to professional cleanroom installation teams if requested

Q: Do cleanroom LED lights save electricity?

A: Yes. Modern cleanroom LED lights consume significantly less power than traditional fluorescent lamps. They also:

-

Do not emit heat → do not raise room temperature

-

Have long service life → reduce replacement and maintenance costs

If you are looking for GMP‑standard LED panel solutions for pharmaceutical, food, cosmetics factories, or need guidance for cleanroom lighting design, VCR is a reliable partner:

-

Products are in stock and shipped quickly across the country

-

Technical consultations align with GMP/WHO standards

-

Full documentation (CO, CQ) simplifies audit acceptance

-

24‑month warranty ensures peace of mind

Contact us now:

Hotline: 090.123.9008

Email: [email protected]

Website: https://denphongsach.com/

Dat VCR