Cleanroom lighting maintenance plays an important role in maintaining standard brightness and ensuring a GMP, ISO 14644 compliant production environment. Regular inspection, cleaning and replacement helps prevent lumen loss, detect damage early and maintain stable light quality in the cleanroom.

- 1. Why is regular maintenance of cleanroom lighting necessary?

- 2. Recommended cleanroom lighting maintenance schedule

- 3. Standard procedure for cleanroom lighting maintenance

- 4. Signs That Cleanroom Lights Need Immediate Replacement

- 5. Common Mistakes in Cleanroom Lighting Maintenance

- 6. Suggested Lighting Maintenance Procedures by Industry

- 7. Frequently Asked Questions About Cleanroom Light Maintenance

- 8. Need Help Maintaining Cleanroom Lighting? Contact VCR Today!

In a production environment that requires high cleanliness such as pharmaceutical, electronics or food processing factories, lighting system maintenance is a step that cannot be overlooked. When it comes to cleanroom lighting maintenance, you do not simply replace the bulb when it breaks, but also need to perform periodic inspection, cleaning and maintenance steps to maintain standard brightness, prolong the life of the equipment and ensure that the production process is not interrupted. In this article, VCR will guide you in detail on how to maintain cleanroom lighting - from choosing the right time, implementation process to safety notes to remember - to help you keep the lighting system in optimal condition.

1. Why is regular maintenance of cleanroom lighting necessary?

In a cleanroom environment, lighting not only serves the purpose of illumination but also plays a role in controlling product quality and inspection. Regular maintenance of cleanroom lights is a mandatory requirement in GMP or ISO 14644-compliant systems, for the following reasons:

1. Maintain standard brightness levels by area

Cleanroom lighting standards typically range from 300–500 lux, depending on the location of use (production area, inspection, packaging, etc.).

Without regular maintenance, lighting can degrade significantly, leading to operational errors and difficulty in detecting foreign objects or product defects.

2. Prevent lumen depreciation over time

Cleanroom LED lights typically have a lifespan of 25,000–50,000 hours, but luminous flux (lumen output) begins to decrease after about 2–3 years.

Measuring and recording illuminance (lux) helps determine when cleaning or replacement is needed to maintain brightness levels.

3. Early detection of damage – minimize production risks

Issues such as flickering, color shifting, or dust ingress into the lamp body—if not addressed promptly—can cause secondary contamination or lead to GMP audit failures.

Routine maintenance helps detect problems early, avoiding production disruption or product rejections due to substandard lighting.

See more: Comparison of UV and LED lamps in clean rooms: Practical applications

2. Recommended cleanroom lighting maintenance schedule

To ensure stable lighting performance and compliance with ISO/GMP standards, each type of cleanroom light should follow a specific inspection and maintenance cycle. Below are recommendations based on practical operations in pharmaceutical, food, and electronics plants:

|

Type of Light |

Inspection Frequency |

Suggested Maintenance Task |

|

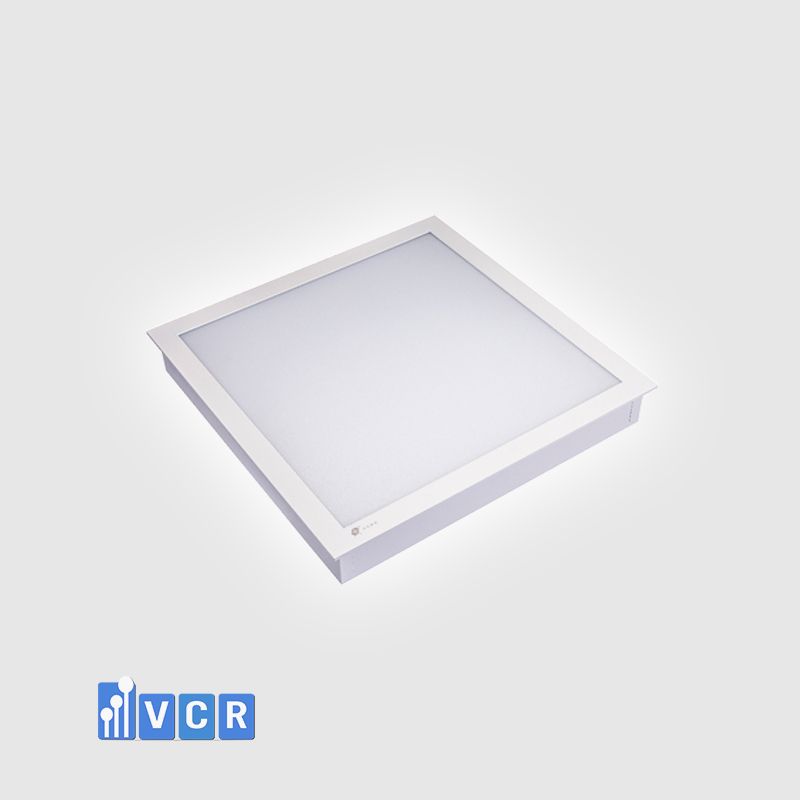

LED Panel Light |

Every 6 months |

Clean surface, measure luminous flux (lux) |

|

Moisture/Explosion-proof Light (IP65) |

Every 3 months |

Check rubber gasket, clean housing |

|

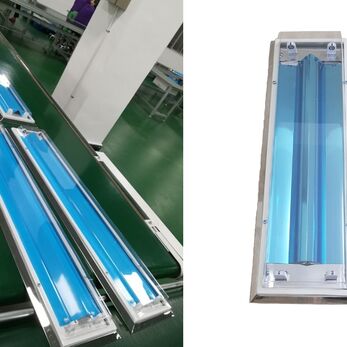

UV Sterilization Light |

Monthly |

Check UV runtime, clean surface |

Professional tip: Schedule light maintenance alongside HVAC and air filtration equipment servicing to optimize manpower and inspection time. Synchronizing these helps reduce the risk of omissions and improves airborne contamination control.

Additionally, maintenance logs should follow internal SOP templates and include:

- Light name, installation position code

- Maintenance date, responsible technician

- Measured lux value and remarks (needs cleaning/replacement)

3. Standard procedure for cleanroom lighting maintenance

To ensure cleanroom lights maintain stable brightness and do not compromise air cleanliness, the maintenance process must follow clear steps and minimize dust generation or mishandling:

Step 1: Safely cut off the power

Turn off the power from the main breaker or local circuit.

Place a warning sign: “Under Maintenance – Do Not Switch On.”

Step 2: Properly remove and clean the light

Use a lint-free or microfiber cloth to gently wipe the light surface and reflective components.

Avoid using strong solvents that may damage protective coatings.

Step 3: Measure illuminance at the working height

Use a lux meter to measure brightness at the actual working height (typically 0.8–1.2 meters).

Record the results for each specific light fixture location.

Step 4: Compare with industry-specific lighting standards

|

Industry |

Recommended Lux Levels |

|

Pharmaceuticals |

400–500 lux (inspection area) |

|

Food |

300–500 lux |

|

Electronics |

500–750 lux (e.g., SMT areas) |

If the measured illuminance is 20% lower than the standard → cleaning or replacement is required.

Step 5: Record and evaluate

Document the results in the lighting maintenance log.

Provide recommendations: continue using, schedule replacement, or recheck within a short period.

See more: Where you should buy Cleanroom Lights

4. Signs That Cleanroom Lights Need Immediate Replacement

LED lights don’t have to “burn out” before being replaced. In cleanroom environments, even minor defects can lead to loss of light control or airborne contamination. Below are signs that indicate lights should be replaced immediately:

1. Flickering or color shifting light

The color shifts from white to yellow, green, or becomes inconsistent.

Flickering occurs frequently, especially during system startup or shutdown.

2. Uneven light distribution

Some areas are bright while others are dim, despite using the same type of light.

This makes product inspection or manual tasks difficult.

3. Luminous flux decreased by more than 20%

Measured lux is less than 80% of the original installation value.

This suggests that the LED chip has degraded and the light needs replacing.

4. Physical deterioration of the fixture

Cracked housing, moisture ingress, cloudy light diffuser, or visible dust inside the fixture.

These issues reduce lighting performance and can compromise cleanroom classification.

5. Common Mistakes in Cleanroom Lighting Maintenance

Although maintaining lights may seem simple, improper procedures can damage equipment, violate cleanroom standards, or result in subpar lighting. Below are common errors and how to avoid them:

|

Maintenance Error |

Consequence |

Corrective Action |

|

Using strong solvents (acetone, gasoline) |

Dulls light diffuser, damages anti-dust coating |

Use 70% isopropyl alcohol or a neutral cleaner |

|

Not measuring lux after cleaning |

Undetected drop in illuminance after wiping |

Always measure lux after every cleaning |

|

Improper disassembly |

Breaks dust seals, compromises IP65 rating |

Follow manufacturer’s installation instructions |

|

Cleaning while power is on |

Risk of short circuit, electric shock, or fire |

Turn off power and post a safety warning sign |

|

Failing to log maintenance results |

Lacks proof during GMP/ISO audits |

Maintain maintenance log with lux readings and photos |

See more: User Guidelines for Cleanroom LED Light

6. Suggested Lighting Maintenance Procedures by Industry

Each industry that uses cleanrooms has specific technical and compliance requirements. Cleanroom lighting maintenance procedures should therefore be tailored to the application context:

Pharmaceuticals (GMP EU/WHO)

Lighting directly affects tasks such as drug inspection, labeling, and color differentiation.

All maintenance records should follow SOPs in compliance with GMP.

Suggestions:

- Maintain signed maintenance logs (by QC or QA personnel)

- Take before-and-after photos to document maintenance actions

- Prepare periodic illuminance assessment reports by production zone

Food Industry

Lights must be dust- and moisture-resistant (IP65 or higher) due to environments with steam and grease.

Maintenance should include physical inspection of housing and gaskets.

Suggestions:

- Check enclosure seals to prevent contamination

- Use explosion-proof moisture-resistant lights in prep/packing areas

- Coordinate light cleaning with ceiling panel maintenance

Cosmetics / Electronics Industry

High-quality lighting is required to detect micro-defects (cosmetics: color, bubbles; electronics: solder joints, particles).

In addition to lighting, ESD and cleanroom pressure must be managed.

Suggestions:

- Combine lighting maintenance with:

- ESD measurement if anti-static control is required

- Pressure differential checks to evaluate lighting system impact

- Use LED panel lights with CRI ≥ 80 to improve color accuracy during quality checks

7. Frequently Asked Questions About Cleanroom Light Maintenance

1. Is it necessary to shut down the entire system during lighting maintenance?

Not necessarily. If the electrical system is designed in isolated zones, you can shut off power locally in the area under maintenance without disrupting the entire production line. However, safety must be ensured, and proper warning signs should be displayed.

2. How often should cleanroom LED lights be replaced?

Cleanroom LED lights typically last between 25,000 and 50,000 hours, equivalent to about 3–5 years depending on usage. When luminous flux drops more than 20% or light defects occur, replacement is recommended to maintain GMP/ISO compliance.

3. Should a luxmeter be calibrated?

Yes. To ensure accurate illuminance measurements, the luxmeter should be calibrated every 12 months, preferably by a service provider certified to ISO/IEC 17025. An uncalibrated device may yield significant errors, affecting lighting assessments.

8. Need Help Maintaining Cleanroom Lighting? Contact VCR Today!

Are you struggling with:

- Setting up a regular cleanroom lighting maintenance schedule?

- Measuring lux but unsure how to compare it with standards?

- GMP audit comments regarding substandard lighting?

The VCR technical team is ready to assist you:

- Consultations on creating lighting maintenance SOPs by industry

- Provision of complete ISO/GMP lighting standard charts

- Sample maintenance logs and lux assessment report templates

Hotline: 090.123.9008

Email: [email protected]

Website: https://denphongsach.com/

Diep VCR