Cleanroom lighting not only determines visual efficiency but also affects operational accuracy and product quality control. So, cleanroom lighting standards: Are they mandatory? - let's learn in detail about the requirements for illuminance, CRI, color temperature and regulations applicable in each industry.

- 1. What Are Cleanroom Lighting Standards?

- 2. Is Cleanroom Lighting Mandatory?

- 3. Why Is Lighting Important in Cleanrooms?

- 4. Standard Lighting Levels by Cleanroom Zone

- 5. How to Choose the Right Cleanroom Lighting

- 6. Common Mistakes When Installing Cleanroom Lighting

- 7. Frequently Asked Questions About Cleanroom Lighting

- 8. Need Help Choosing Certified Cleanroom Lighting?

1. What Are Cleanroom Lighting Standards?

Lighting in cleanrooms is not just about visibility—it directly impacts operational accuracy, contamination detection, and overall product quality control. Therefore, cleanroom lighting is strictly regulated in many industries.

Cleanroom lighting standards – In simple terms:

These are technical requirements related to illuminance (Lux), color rendering index (CRI), color temperature (Kelvin), and lighting uniformity. The goal is to ensure optimal working conditions while minimizing contamination risks or operational errors.

Key lighting parameters to know:

|

Parameter |

Meaning |

Recommended for Cleanrooms |

|

Lux (illuminance) |

Light intensity per square meter |

500 – 1000 Lux depending on zone |

|

CRI |

Accuracy of color rendering under the light source |

≥ 80 |

|

Color temperature |

The warmth or coolness of light tone |

4000K – 6000K (neutral to cool) |

|

Uniformity ratio |

Avoiding dark zones and shadows |

≥ 0.7 according to EN 12464-1 |

Lighting standards applied in cleanrooms:

- ISO 14644: While mainly focused on particle control, ISO 14644-4 addresses lighting suitability for maintenance and operational visibility.

- GMP EU (Annex 1): Requires lighting design sufficient for contamination detection in pharmaceutical manufacturing areas.

- FDA 21 CFR Part 211: Mandates adequate lighting for visual inspections and precise operations in drug manufacturing.

- EN 12464-1: European standard for workplace lighting – applicable to weighing rooms and laboratories.

These standards demand more than just "having light" — they require "the right intensity, function, and compatibility with cleanroom environments."

2. Is Cleanroom Lighting Mandatory?

The answer depends on the industry and intended use of the cleanroom. Some sectors enforce mandatory lighting standards, while others suggest best practices that are still critical for quality and operational safety.

Pharmaceutical industry: Mandatory under GMP EU & WHO

Standards like GMP EU Annex 1, WHO GMP, and FDA 21 CFR Part 211 clearly require sufficient lighting to:

- Detect contamination or product defects

- Perform visual inspections

- Ensure precise operations in sterile environments

In GMP audits, insufficient lighting in key areas (e.g., production or weighing rooms) can result in major non-conformities.

Cosmetics industry: Strong recommendation under ISO 22716

ISO 22716 – Guidelines for Good Manufacturing Practices in cosmetics – does not specify Lux levels, but strongly recommends proper lighting to:

- Avoid mistakes during filling and packaging

- Maintain consistent product appearance

- Support equipment and hygiene inspections

Food industry: Required for quality control

Standards such as HACCP and ISO 22000 require lighting in food processing areas to:

- Be strong enough to detect contaminants or residue

- Not distort product appearance

- Avoid dark zones where microbial growth can occur

Some export markets mandate lighting levels ≥ 500 Lux in fresh product handling zones.

Electronics industry: Not mandated, but practically essential

While ISO 14644 does not explicitly require lighting specifications, the industry involves:

- Micro-component assembly

- Visual checks under magnifiers

- Electrostatic discharge control environments

→ Inadequate lighting can lead to high error rates, product defects, and reinspection costs.

Legal Requirement vs. Operational Necessity

|

Industry |

Legal Requirement |

Operational Quality Requirement |

|

Pharmaceuticals |

Yes |

Yes |

|

Cosmetics |

Recommended |

Needed to avoid packaging errors |

|

Food |

Required under HACCP |

Crucial for export product quality |

|

Electronics |

Not mandated |

Highly needed to reduce assembly errors |

Summary: Not every sector legally mandates cleanroom lighting, but if your goal is to meet audit standards and maintain high-quality output, proper lighting becomes non-negotiable.

See more: Latest price list of clean room lights used in medical clean rooms

3. Why Is Lighting Important in Cleanrooms?

In cleanroom environments where a single dust particle can ruin an entire batch, lighting serves not just for visibility but as a critical tool for quality control and operational safety.

1. Easier detection of dust, particles, and contamination

Proper lighting with adequate intensity and correct color temperature (4000–6000K) helps staff easily spot dust, stains, or foreign objects in production areas.

This is especially vital in:

- Filling and packaging areas

- Weighing and laboratory rooms

- Areas with direct product contact

If lighting is too dim or improperly toned, small contamination points may go unnoticed.

2. Enhances work efficiency and reduces errors

Well-lit environments improve focus and reduce eye fatigue during prolonged tasks.

In industries like electronics, pharmaceuticals, or healthcare, proper lighting helps prevent:

- Component mix-ups

- Operational mistakes due to visual fatigue

3. Prevents glare and shadow-related hazards

Uneven lighting creates glare and shadows, which may:

- Obstruct visibility of tools or surfaces

- Hide contamination under shaded zones

- Increase technical error rates

Cleanroom lighting should be glare-free, evenly diffused, and have a high Color Rendering Index (CRI ≥ 80) for accurate visibility.

4. Critical for final QA/QC inspections

Quality Assurance and Control (QA/QC) departments typically require lighting levels of 750–1000 Lux for:

- Visual inspections

- Detecting micro-defects

- Verifying packaging and label consistency

GMP-compliant factories often require measured illuminance reports at key inspection points, as part of their audit documentation.

See more: Navigating FDA and ISO Standards for Clean Room Lighting in Food Manufacturing

4. Standard Lighting Levels by Cleanroom Zone

Not all cleanroom zones require the same illuminance. Based on functionality and precision levels, international standards define specific Lux recommendations to ensure optimal operation and inspection accuracy.

Table: Recommended Lighting Levels in Cleanrooms

|

Cleanroom Zone |

Recommended Lux Level |

Reference Standard |

|

Main Production Area |

500 – 1000 Lux |

GMP EU Annex 1 |

|

Weighing Room / Lab Inspection |

750 – 1000 Lux |

ISO 14644-4 / ISO 14644-5 |

|

Changing Room (Airlock) |

200 – 400 Lux |

EN 12464-1 |

|

Technical Corridor / Utility Area |

150 – 300 Lux |

WHO GPP / ISO 14644-4 |

5. How to Choose the Right Cleanroom Lighting

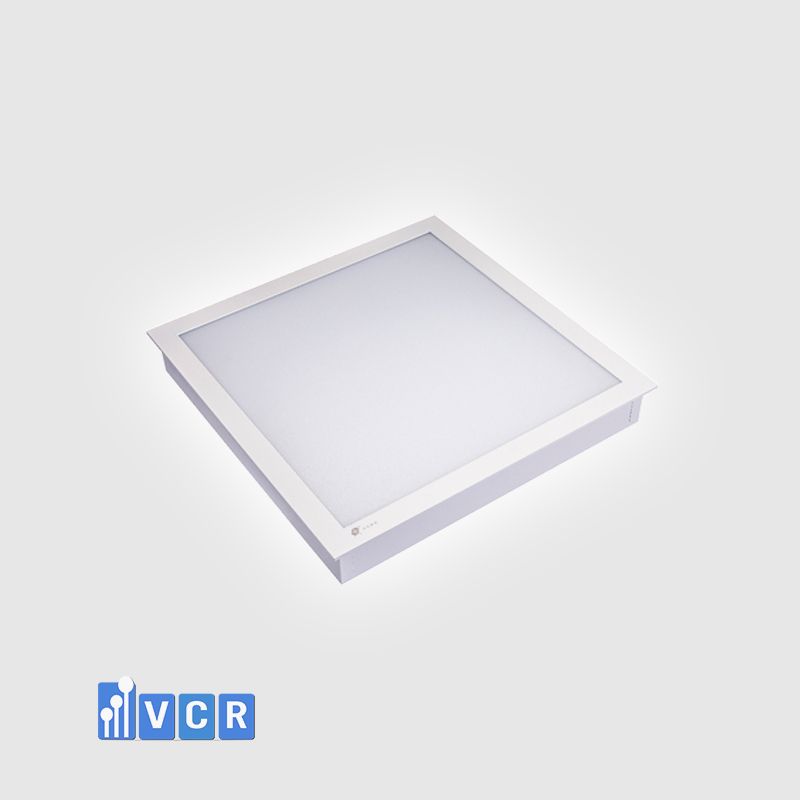

Selecting the right lighting not only ensures compliance with operational standards but also prevents issues like dust buildup, electrostatic discharge, and functional errors.

In tightly controlled environments (e.g., GMP or ISO 14644 cleanrooms), standard commercial LEDs are insufficient. You must choose specialized cleanroom LED panel lights.

Mandatory Technical Criteria for Cleanroom Lights:

- Ingress Protection Rating: IP65 or higher

Full protection against dust

Water-resistant – easy to clean and suitable for sanitized environments - CRI ≥ 80 (Color Rendering Index)

Ensures true-to-life color for accurate defect or label detection during QA/QC - Color Temperature: 4000K – 6000K

Neutral to cool white

Enhances focus and reduces eye strain during long shifts - Flicker-Free Technology

Prevents headaches and visual fatigue

Critical in areas requiring visual precision - Flat-surface design (no dust-trapping crevices)

Panel-style recessed or surface-mounted lights

Reduces airflow disruption and facilitates routine cleaning - Smart system compatibility (optional)

Supports integration with motion sensors, timers, or BMS for energy optimization

See more: Where you should buy Cleanroom Lights

6. Common Mistakes When Installing Cleanroom Lighting

Even if the correct type of lighting is selected, improper installation or lack of maintenance can severely impact cleanroom performance and quality control.

Here are three of the most common mistakes found in cleanroom facilities:

1. Using non-compliant commercial lighting

- Lights without proper IP rating → Easily allow dust ingress, contaminating the cleanroom

- Low CRI → Makes it difficult to detect stains, discoloration, or product defects

- Not anti-static compliant → Increases the risk of component failure, especially in electronics manufacturing

This is the most common but also most dangerous mistake, as it directly violates cleanroom standards.

2. Poor light placement causing shadows

- Misaligned or unevenly spaced lighting → Creates dark zones on work surfaces

- No anti-glare design → Causes visual discomfort and reduced visibility

- Improper spacing → Leads to non-uniform lighting distribution

Result: Increased human error, missed foreign objects, and higher product defect rates.

3. Lack of routine lux level checks

Lighting performance can degrade over time due to:

- Dust accumulation on diffusers

- LED degradation after thousands of hours of operation

If illuminance levels are not re-measured every 6–12 months, the lights may still appear bright but no longer meet the original design standards.

See more: 5 Basic things about clean room lights that you need to know

7. Frequently Asked Questions About Cleanroom Lighting

1. Do cleanroom lights need certifications?

Yes — especially if your facility operates under GMP EU, WHO GMP, or ISO 14644 standards.

Recommended certifications include:

- RoHS: Ensures the lights are free from hazardous substances and environmentally friendly

- CE: Complies with European safety and quality standards

- Lux Test Report: Confirms that lighting meets specified brightness levels in each designated cleanroom zone

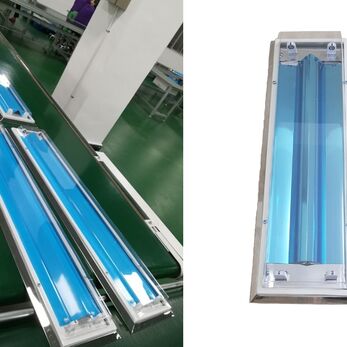

2. Can I use LED tube lights in cleanrooms?

Yes, but not standard commercial models.

LED tube lights in cleanrooms must:

- Be enclosed in anti-dust, anti-static casings

- Have a sealed design (IP65 or higher)

- Include a soft-diffused cover to reduce glare and prevent dust buildup

- Be surface-mounted or recessed (not exposed fixtures that create gaps)

3. Can I use automatic light sensors in cleanrooms?

Yes — this is a growing trend in energy-efficient manufacturing facilities.

However, two conditions must be met:

- Lighting fluctuation must not exceed ±10% from the design standard — especially in critical zones like weighing or testing areas

- The control system must include logging and supervision to prevent unintentional adjustments during operation hours

8. Need Help Choosing Certified Cleanroom Lighting?

If you're:

- Unsure which lighting solution suits each cleanroom zone

- Preparing for GMP or ISO audits and need certified lux reports

- Looking to optimize costs without compromising lighting quality

Let the VCR cleanroom lighting experts assist you.

We provide:

- LED panel lights designed specifically for cleanroom use (IP65, CRI ≥ 80, flicker-free)

- Lighting layout consultation based on your cleanroom floor plan

- On-site lux measurement services and certified lighting documentation by zone

Hotline: 090.123.9008

Email: [email protected]

Website: https://denphongsach.com/

Diep VCR