Clean room lights are specialized lighting equipment in food processing factories, helping to ensure a safe, clean working environment and meeting strict inspection standards. This article updates the latest clean room light price list, analyzes the factors affecting the price and suggests choosing the right type of light for each production area.

- 1. General Introduction

- 2. Latest Price List for Cleanroom Lights in Food Factories

- 3. Factors Affecting Cleanroom Light Prices

- 4. Recommendations for Choosing Cleanroom Lights in Food Plants

- 5. Benefits of Using Certified Cleanroom Lights

- 6. FAQ - Frequently Asked Questions

- 7. Contact for Consultation & Quotation

1. General Introduction

In the food production environment, lighting not only serves ordinary illumination purposes but also plays a crucial role in ensuring hygiene, safety, and product quality. Cleanroom lights are specially designed with dustproof, moisture-proof, and easy-to-clean features, meeting strict lighting standards. They help minimize cross-contamination risks, create safe working conditions for employees, and meet the industry's strict inspection requirements.

Importance of choosing the right light to meet HACCP, ISO 14644, GMP standards

Selecting lights that do not meet standards can expose factories to many risks, from failing HACCP certification, violating ISO 14644 cleanroom classification, to not complying with GMP production standards. Choosing the right certified lights ensures:

- Uniform, glare-free lighting for accurate product inspection.

- Compliance with IP protection ratings and suitability for the food production environment.

- Easy maintenance and cleaning without affecting production operations.

Benefits of updating the latest price list before investing

Given constant fluctuations in raw material costs and technology, updating the latest cleanroom light price list helps businesses:

- Plan budgets accurately and avoid unexpected extra costs.

- Choose products that are optimal in both performance and cost.

- Take advantage of promotions and discounts from suppliers to optimize initial investment costs.

See more: 5 Basic things about clean room lights that you need to know

2. Latest Price List for Cleanroom Lights in Food Factories

Overview of standards and technical requirements

In the food industry, lighting systems must meet multiple strict standards:

- HACCP: Ensure lighting equipment poses no contamination risk.

- ISO 14644: Meet cleanroom level requirements (ISO 7, ISO 8) with dust and microbial resistance.

- GMP: Fit production processes, easy to clean and maintain without compromising food safety.

Additionally, cleanroom lights should have IP65 protection or higher to resist dust and water, high Color Rendering Index (CRI) for accurate product color representation, and energy efficiency with long lifespan.

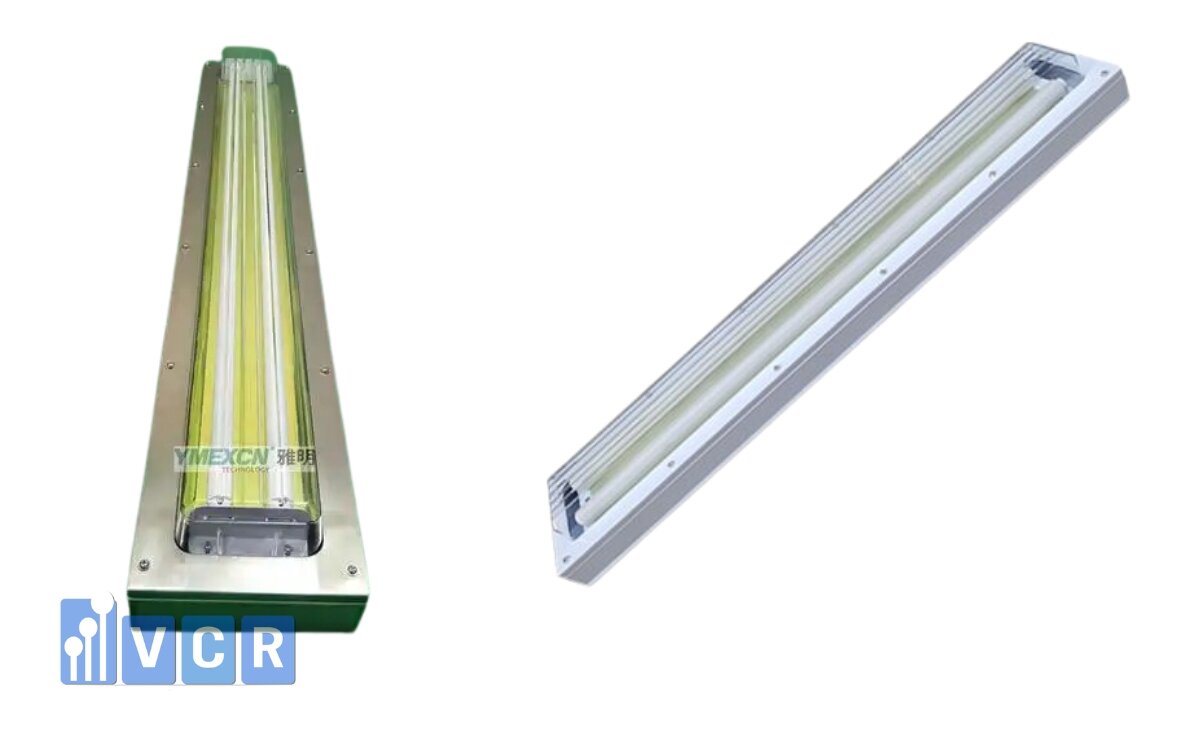

Detailed Price List (Latest Update)

|

Light Type |

Power (W) |

Standard |

Price Range (VND) |

Application |

Key Advantages |

|

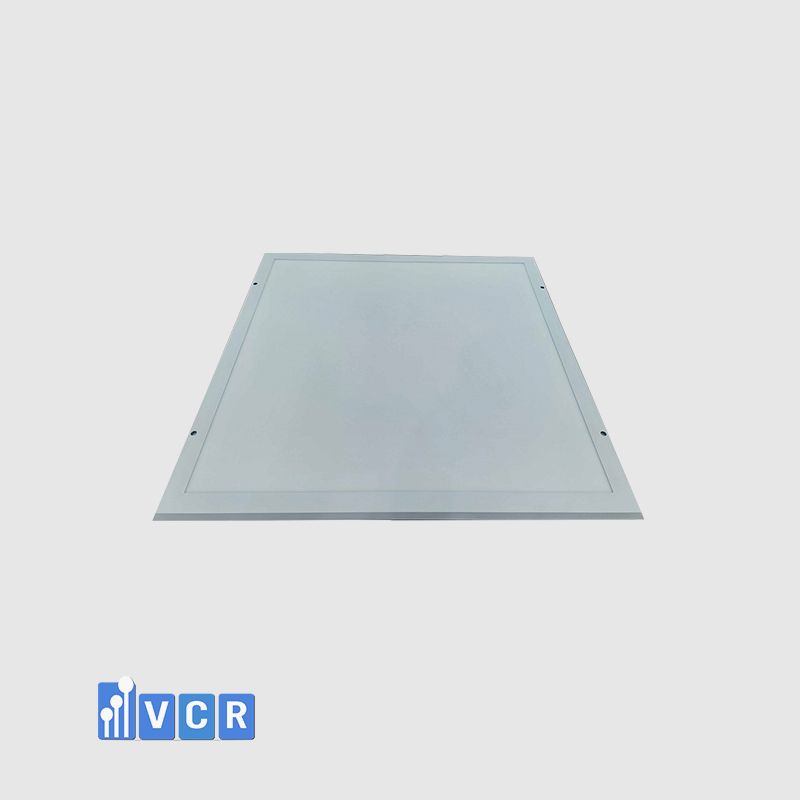

LED Panel IP65 |

36W |

IP65, ISO 8 |

1,650,000 - 1,950,000 |

Main processing areas |

Even light, dust & water resistant, lifespan 40,000h+ |

|

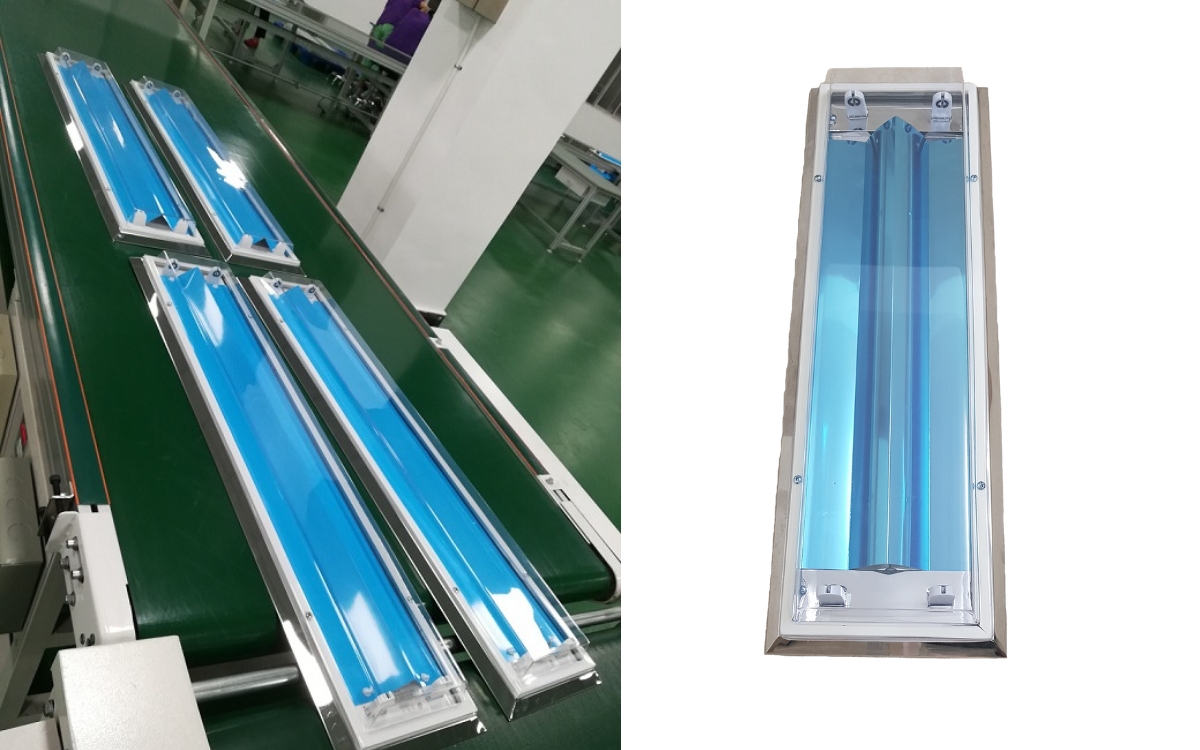

Moisture-proof LED Tube |

18W |

IP65, ISO 7 |

950,000 - 1,200,000 |

Packaging areas, corridors |

Compact, flexible installation, high moisture resistance |

|

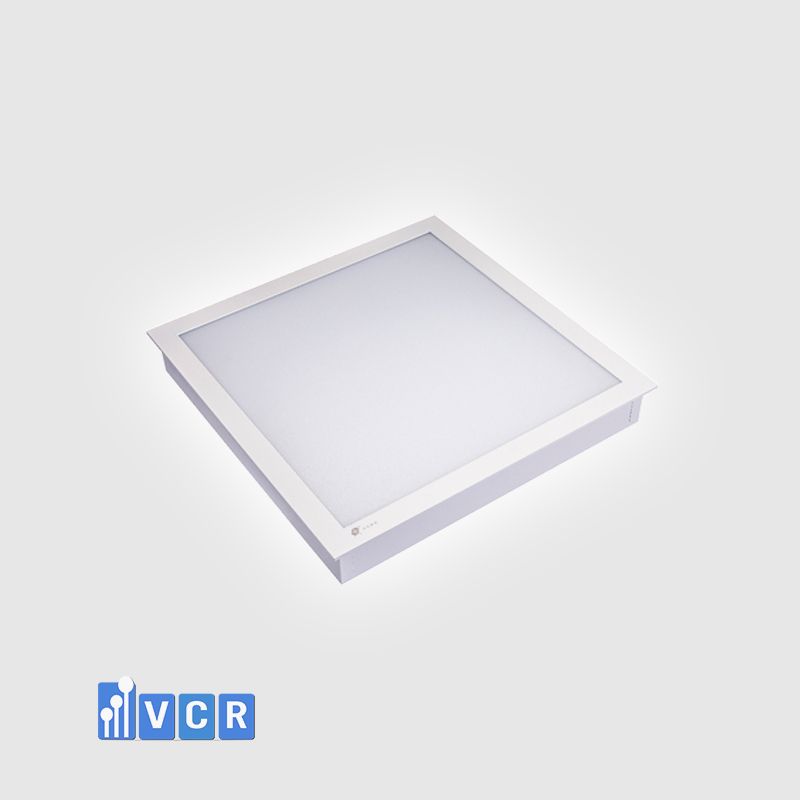

Recessed LED |

24W |

IP65, ISO 7-8 |

1,250,000 - 1,550,000 |

Changing rooms, airlocks |

High aesthetics, energy saving, soft light |

|

Industrial Moisture-proof LED |

20W |

IP65, ISO 8-9 |

1,050,000 - 1,300,000 |

Storage areas, auxiliary rooms |

Durable in humid environments, easy maintenance |

|

Anti-glare LED Panel |

36W |

IP65, CRI ≥ 85 |

1,850,000 - 2,200,000 |

Quality control areas |

Reduces eye strain, accurate color rendering, anti-glare |

Notes on price conditions and extra costs

- Prices include lights and basic accessories, excluding VAT.

- Installation costs depend on project scale, ceiling height, and technical requirements.

- Bulk orders or turnkey contracts receive special discounts.

- Some brands may cost more due to premium LED chips, longer warranties, or additional fire/UV resistance standards.

See more: Key Considerations in Designing Cleanroom Lighting Systems

3. Factors Affecting Cleanroom Light Prices

Lighting prices depend not only on brand but also on technical specifications and actual site conditions.

Cleanroom standards and IP protection rating

- Cleanroom standards (ISO 14644, HACCP, GMP) require lights to minimize dust/microbial ingress and be easy to clean.

- IP rating indicates dust/water resistance:

- IP65: Fully dustproof, withstands low-pressure water jets.

- IP66/IP67: Stronger water resistance, suitable for humid or washable ceilings.

- Higher ratings mean more complex structures and higher prices.

LED chip type and luminous efficacy

- Premium chips (Osram, Philips, Nichia…) offer high luminous efficacy (≥ 120 lm/W), saving energy and maintaining brightness longer.

- Cheaper LEDs may reduce upfront costs but dim quickly and have shorter lifespans.

Color Rendering Index (CRI) and color temperature

- CRI:

- CRI ≥ 80: Suitable for production & packaging.

- CRI ≥ 90: Needed for quality inspection.

- Color temperature:

- 4000-5000K: Neutral white, reduces eye strain.

- 6000-6500K: Cool white, for large production areas.

Housing material & dust/waterproof design

- Powder-coated steel or anodized aluminum housings increase durability.

- PC or tempered glass covers provide impact resistance.

- Rounded, sealed designs prevent dust buildup and ease cleaning.

Installation, maintenance & warranty costs

- High ceilings or difficult access raise installation costs.

- Humid/oily environments require more frequent maintenance.

- Long warranties (≥ 2 years) reduce repair/replacement risks.

Conclusion: Balance initial investment with long-term operating costs for optimal choice.

See more: 9 Aspects of LED Light Specification You Need to Understand

4. Recommendations for Choosing Cleanroom Lights in Food Plants

Main processing areas

- Recommended: LED Panel IP65 36W or anti-glare LED CRI ≥ 85.

- Why: Even lighting, dust/waterproof, CRI for accurate color checks.

Packaging & storage areas

- Packaging: Moisture-proof LED Tube 18W or LED Panel 24W, neutral white.

- Storage: Industrial moisture-proof LED 20W, IP65-IP66, easy to maintain.

Energy-saving & eco-friendly solutions

- High-efficacy LEDs (≥ 120 lm/W).

- Dimming controllers & motion sensors.

- Mercury & lead-free, recyclable materials.

Choosing reputable suppliers

- CO/CQ certifications & full technical docs.

- GMP/HACCP experience.

- 24+ month warranty & post-sales technical support.

5. Benefits of Using Certified Cleanroom Lights

Ensures food product quality

- Even lighting for defect detection.

- Dust/insect/microbial-proof housing.

- High CRI for accurate color representation.

Optimizes labor productivity & safety

- Reduced eye strain & fatigue.

- Flicker-free, glare-free design.

- IP65-IP67 safety for wet cleaning.

Reduces maintenance & replacement costs

- Lifespan 40,000-50,000h.

- Moisture/dust-proof build.

- Long warranties reduce risks.

Passes inspections & audits

- Complies with regulatory inspections.

- Meets client/partner requirements.

- Enhances brand reputation & competitiveness.

6. FAQ - Frequently Asked Questions

Is IP65 mandatory for food industry cleanroom lights?

Yes. IP65 ensures full dustproofing and water resistance from all directions. In very humid areas, IP66 or IP67 is recommended.

What type of lights for packaging areas?

Neutral white (4000-5000K) LED Panels 24-36W or moisture-proof LED Tubes 18W, IP65 rated.

Does the price include installation?

No. Installation cost depends on ceiling height, number of units, and site conditions.

How long is the warranty?

High-quality cleanroom lights usually have 24-36 month warranties, some up to 5 years.

7. Contact for Consultation & Quotation

- Technical consultation & filter core selection by application: VCR engineers will help identify the most suitable product for your factory's environment & standards.

- Support policy:

- Free test samples before ordering.

- Special pricing for large projects & long-term contracts.

- Nationwide fast delivery.

Hotline: 090.123.9008

Email: [email protected]

Website: https://denphongsach.com/

Diep VCR