Proper lighting in the cleanroom QC area is key to helping employees accurately inspect product color, surface, and defects. Compliance with mandatory lighting standards for cleanroom lighting in the QC area helps ensure the accuracy, safety, and quality of the factory's output.

- 1. The Role of Lighting in the QC Area

- 2. Lighting Standards Required for QC Areas

- 3. Recommended Cleanroom Light Types for QC

- 4. Scientific Lighting Layout Recommendations for QC Areas

- 5. Common Mistakes When Selecting QC Lighting and How to Fix Them

- 6. Recommended Lighting Products for QC - From VCR Cleanroom Lighting

- 7. Frequently Asked Questions

- 8. Looking for QC-Compliant Lighting Solutions?

1. The Role of Lighting in the QC Area

In pharmaceutical, food, cosmetic, and electronics manufacturing facilities, the Quality Control (QC) area serves as the final checkpoint to ensure that only qualified products are released to the market. This zone demands near-perfect precision, and lighting is a critical factor that directly impacts inspection accuracy.

Why is standard-compliant lighting essential in QC?

- Enables visual defect detection: QC personnel need to visually inspect product surfaces to detect foreign particles, dust, cracks, or color deviations. Inadequate or incorrect lighting can cause errors to be overlooked.

- Ensures accurate color rendering: In industries like cosmetics or food, where color is a key quality attribute, lighting with high Color Rendering Index (CRI) is essential for accurate visual evaluation.

- Supports detailed technical inspection: In electronics, deviations of just a few microns can cause functional failures. Standard-compliant lighting helps reveal minute defects during inspection.

Common issues if lighting does not meet standards:

|

Lighting Issue |

Practical Consequence |

|

Low illuminance (<500 lux) |

Difficult to detect defects; higher risk of oversight |

|

Low CRI (<80) |

Inaccurate color perception; missed color-related flaws |

|

Uneven lighting |

Dark spots and shadows hinder full-surface inspection |

|

Flickering (even slight) |

Eye strain, lower work efficiency, and visual misjudgment |

Quality control results are only reliable when lighting conditions comply with regulatory standards. Therefore, investing in cleanroom-grade lighting for QC areas is not just a technical requirement, but also a guarantee of final product quality.

See more: Comparison of UV and LED lamps in clean rooms: Practical applications

2. Lighting Standards Required for QC Areas

To ensure consistent and accurate quality control processes, lighting in QC areas must strictly comply with GMP WHO and ISO 14644 standards. Below are the key technical specifications to consider when designing lighting systems for QC cleanrooms:

Lighting Requirements for QC Cleanrooms

|

Lighting Factor |

Recommended Standard |

Important Notes |

|

Illuminance (Lux) |

≥ 500 Lux |

Ensure sufficient brightness; ≥750 Lux may be needed for fine-detail inspection |

|

CRI (Color Rendering Index) |

≥ 80 |

The higher the CRI, the more accurate the color rendering-important for inspecting printed packaging, cosmetics, tablets, etc. |

|

Color Temperature (CCT) |

4000K - 6500K |

Neutral to cool white light minimizes color distortion |

|

Light Uniformity |

≥ 0.8 |

Prevents shadowed or dim areas that could obscure defects |

|

Flicker |

Not allowed |

Even minor flicker causes eye fatigue and may lead to inspection errors |

Additional notes:

- These standards apply not only to QC areas but also to weighing rooms, packaging lines, and sample analysis zones.

- Illuminance should be measured at the work surface using a calibrated lux meter and validated every 6-12 months.

- CRI ≥ 90 is strongly recommended for color-critical inspection areas (e.g., cosmetics, food, printed materials).

Investing in a cleanroom-compliant lighting system for QC not only ensures regulatory compliance but also reduces recall risks and builds trust during GMP audits and quality inspections.

3. Recommended Cleanroom Light Types for QC

Not all lighting systems are suitable for QC areas within cleanrooms. The fixtures selected must not only meet GMP lighting specifications but also function reliably in strictly controlled environments, free of contamination and particulate dispersion.

Recommended Lighting Types for QC Cleanrooms:

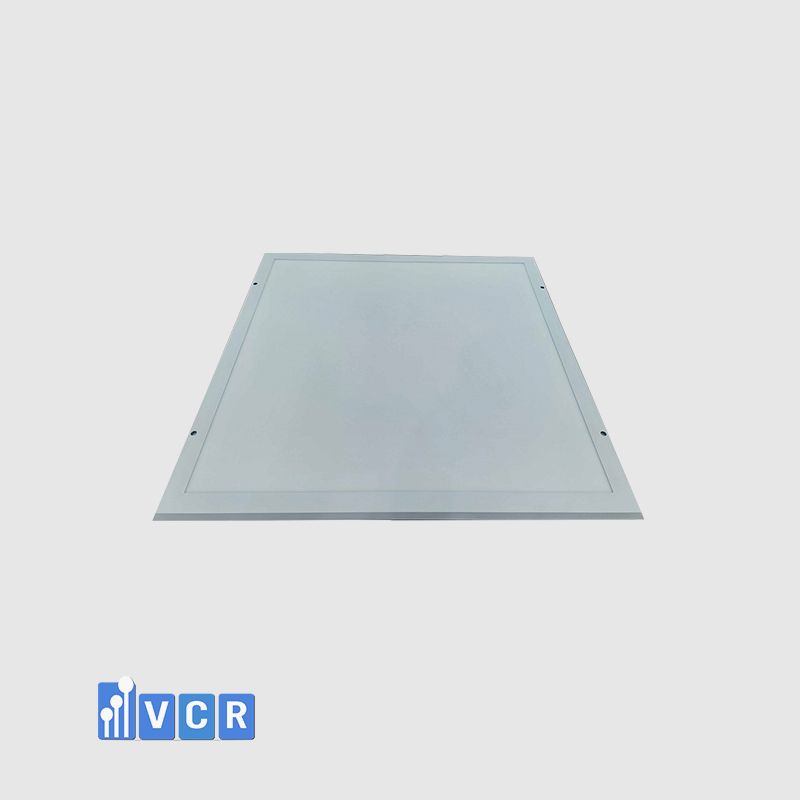

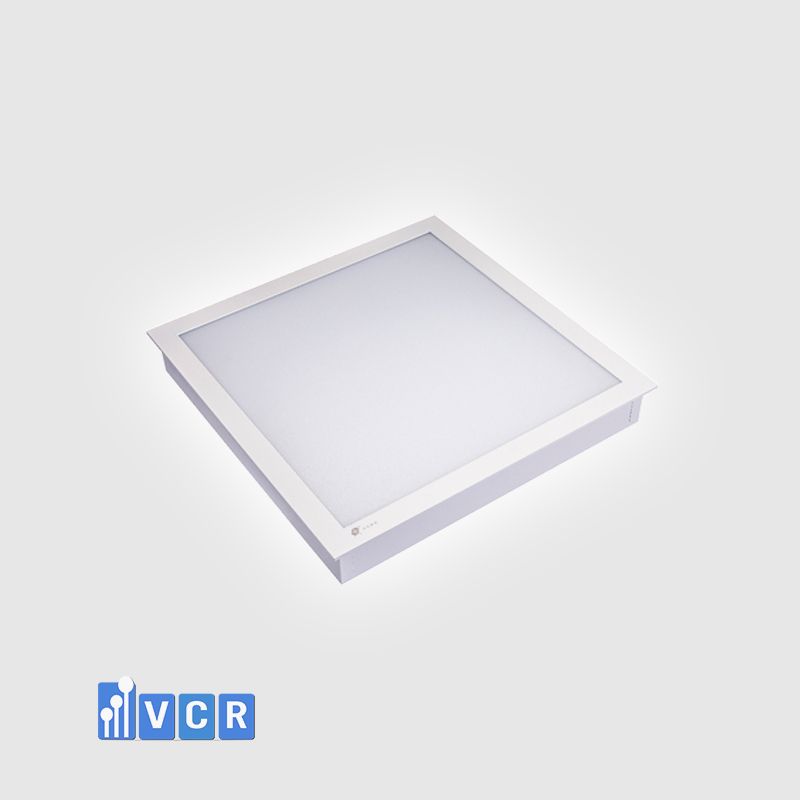

1. LED Panel Cleanroom Lights

- Recessed or surface-mounted types (600x600mm or 300x1200mm)

- Broad, even light distribution ideal for inspecting large areas

- High illuminance (≥500 Lux) and CRI > 80 for defect visibility

- Easy to install; compatible with cleanroom ceiling panels

Best for: Finished product inspection areas, sample testing labs, continuous inspection lines

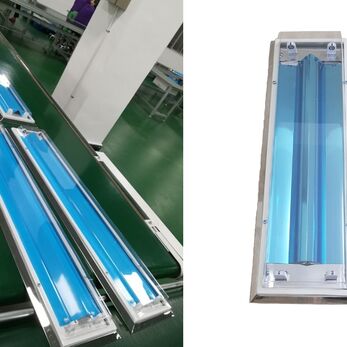

2. LED Tube Fixtures with Dustproof Diffusers

- Single or double T8 LED tubes enclosed in sealed fixtures

- Diffuser covers (e.g., PMMA or polycarbonate) reduce glare and improve uniformity

- Sealed design prevents dust accumulation and microbial growth

Best for: QC corridors, weighing rooms, buffer zones

3. High-CRI Downlights for Small Rooms

- Compact recessed lights providing focused illumination

- CRI up to 90-ideal for color assessment

- Suitable for small QC rooms with specific inspection tasks

Best for: Cosmetic shade matching, printed packaging checks, tablet surface inspection

Mandatory Features for QC Cleanroom Lights:

- Sealed against dust and insect ingress

- No ozone generation or UV emission-safe for both operators and sensitive products

- Smooth, chemical-resistant surfaces for easy disinfection

- Compliance with ISO 14644-1 Class 7-8 or GMP EU/WHO cleanroom standards

- Certified with EMC, ROHS, and CE for electrical and electromagnetic safety

Do not use conventional office lighting or commercial fluorescent lamps in QC zones. These are prone to dust accumulation, may generate flicker or UV, and often fail to meet cleanroom specifications.

See more: Cleanroom LED panel lights: How to choose lux for each cleanliness level

4. Scientific Lighting Layout Recommendations for QC Areas

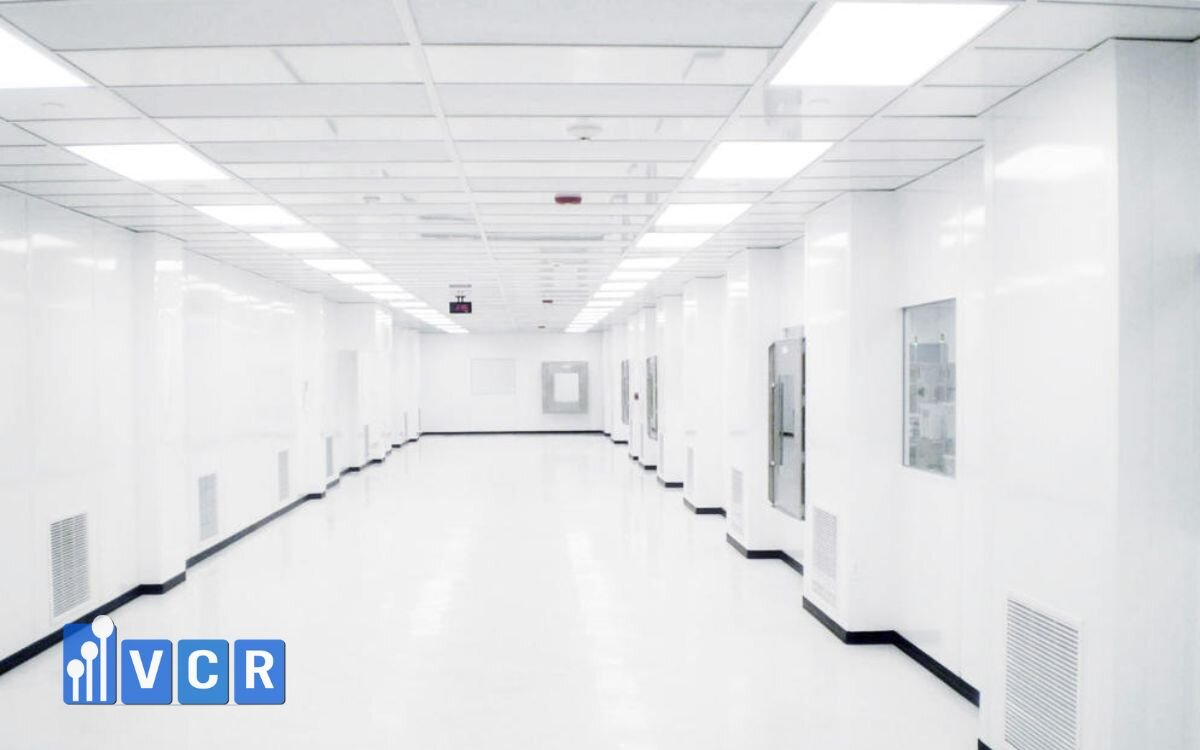

Compliant lighting in a QC zone depends not only on the type of light fixtures used but also on how the lighting system is scientifically arranged and optimized according to room size and functional needs. The following are key principles and practical suggestions to ensure effective lighting aligned with GMP/ISO standards:

Light Spacing for Achieving ≥500 Lux Illuminance

- General rule: The distance between light fixtures should not exceed 1.2 times the height from ceiling to work surface.

- For ceiling heights of 2.7-3m, an appropriate distance between 600x600mm LED panel lights is 1.5-2.0m.

- LED tubes or downlights should be arranged in even grid patterns to prevent over-illumination or dark zones.

Uniform Lighting - Avoiding Shadows

- Fixtures should be installed in parallel and symmetrically, in a square grid on the ceiling.

- Avoid single-direction or wall-mounted lighting, as this causes uneven brightness and shadows.

- In areas with tall equipment or workbenches, supplemental under-cabinet or suspended lighting should be added for localized brightness.

Integrating Sensors for Energy Efficiency

- In QC rooms operating in shifts, consider lights with built-in motion or ambient light sensors.

- Use zoned lighting control to power only the areas currently in use, minimizing unnecessary energy consumption.

Sample Lighting Layout for a 20m² QC Room

Assume room size: 4m x 5m, ceiling height: 2.8m

Recommended setup:

- Install 6 recessed 600x600mm LED Panel Cleanroom lights arranged in a grid: 2 rows of 3 fixtures

- Fixture spacing: 1.6-1.8m

- Use fixtures with CRI ≥ 80 and color temperature of 5000K

- Add 1-2 high-CRI downlights at color inspection workstations

See more: Navigating FDA and ISO Standards for Clean Room Lighting in Food Manufacturing

5. Common Mistakes When Selecting QC Lighting and How to Fix Them

Incorrect light selection or improper lighting design in QC areas can lead to serious consequences-from inaccurate product assessment to failure in GMP/ISO inspections. Below are the most frequent issues and their effective solutions.

1. Choosing Lights with Low CRI (<80)

Consequences:

- Product colors appear distorted under inspection

- Surface defects, discolorations, or contamination may be overlooked

Solutions:

- Always select fixtures with CRI ≥ 80; use CRI ≥ 90 for color-critical zones (e.g., cosmetics, packaging, tablets)

- Verify CRI ratings from the technical datasheet of a trusted supplier

2. Poor Planning Leading to Inadequate Lux (<500 Lux)

Consequences:

- Insufficient brightness affects defect detection

- Lighting fails GMP/ISO 14644 compliance during audits

Solutions:

- Use lighting simulation software or measure actual illuminance with a luxmeter

- Conduct routine revalidation every 6-12 months to maintain compliance

3. Using Commercial Office Lights Instead of Cleanroom Lights

Consequences:

- Dust and insects may infiltrate open fixtures

- Surfaces are not chemical-resistant or cleanable

- Increased risk of cross-contamination; non-compliance with GMP

Solutions:

- Use sealed cleanroom-grade lighting-dustproof, moisture-resistant, non-ozone emitting

- Prioritize fixtures rated IP65 or higher, with CE, ROHS certifications, and compliance with ISO 14644-1 Class 7-8

Summary - Comprehensive Lighting Strategy

- Assess lighting needs per QC process step

- Plan light type, quantity, and layout from the design phase

- Equip QC areas with luxmeters for periodic measurement

- Document lighting validation results for audits and compliance

Compliant lighting improves inspection accuracy and supports the establishment of a fully GMP-ready cleanroom environment-from air control to visual clarity.

See more: Choosing the Best Cleanroom Lights for Your Factory

6. Recommended Lighting Products for QC - From VCR Cleanroom Lighting

If you're looking for GMP and ISO-compliant lighting solutions for your QC zones, VCR Cleanroom Lighting offers trusted expertise with over 10 years in the industry.

Selected Cleanroom Lighting Models for QC Areas:

VCR LED Panel Cleanroom 600x600mm

- High illuminance ≥ 500 Lux, CRI ≥ 80

- Uniform light diffusion, glare-free

- Dustproof, insect-resistant, easy to clean

- Suitable for recessed or suspended installation

VCR LED Downlight CRI90

- High color fidelity for product color differentiation

- Ideal for inspecting cosmetics, packaging, and food items

- Compact installation-space-efficient in cleanrooms

VCR LED Tube T8 Dustproof

- Features diffusers to prevent dust and improve light distribution

- Flicker-free, UV-free-safe for both operators and products

- Perfect for corridors, support areas, or compact QC rooms

Key Advantages:

- Fully GMP-compliant - ISO 14644 Class 7-8 certified

- Up to 50% energy savings compared to fluorescent lights

- Warranty of 2-5 years for long-term reliability

- Proven track record in leading pharmaceutical and cosmetic plants in Vietnam

7. Frequently Asked Questions

- How much Lux is required in a QC area?

According to GMP WHO, the QC zone must have a minimum illuminance of 500 Lux at the working surface. For tasks involving fine detail or color checks, 750-1000 Lux is recommended. - Is high CRI necessary for cleanroom lights?

Yes. A high CRI (Color Rendering Index) ensures that the light reveals accurate product colors. In QC areas-especially in cosmetics, food, and printed packaging-high CRI is essential for detecting color inconsistencies and defects.

Recommendation: Use CRI ≥ 80; CRI ≥ 90 is ideal for color-critical inspections. - Can standard office lights be used in a cleanroom QC area?

Not recommended. Conventional office lighting:

- Lacks dust-proof design-may emit particles or allow insect intrusion

- Not resistant to cleanroom disinfectants

- May flicker or emit UV/ozone

Only use cleanroom-specific lighting with certifications (ISO 14644, GMP-compliant) to ensure product safety and regulatory compliance.

8. Looking for QC-Compliant Lighting Solutions?

Lighting in your QC area is not just for visibility-it’s a core part of your GMP/ISO compliance system. Don't let something as small as substandard lighting jeopardize inspections, audits, or product evaluations.

Let VCR Cleanroom Lighting support your facility:

- Tailored recommendations for each QC zone

- Consultation on layouts meeting ≥500 Lux and CRI ≥ 80

- Cleanroom-rated lighting with up to 5-year warranty

- Successfully installed at major pharmaceutical, cosmetic, and food factories

Contact us today for a free consultation:

Hotline: 090.123.9008

Email: [email protected]

Website: https://denphongsach.com/

Diep VCR