Cleanroom LED panel lights play a critical role in maintaining GMP‑compliant manufacturing environments. To satisfy strict inspection requirements, choosing a supplier that can provide GMP‑certified cleanroom LED panels is a key factor. This article helps you understand the criteria for selecting the right lights and supplier for industries such as

- 1. Role of Cleanroom LED Panel Lighting in GMP Factories

- 2. Criteria for Choosing GMP‑Standard Cleanroom LED Panels

- 3. Practical Applications Across GMP Industries

- 4. VCR — Reputable Supplier of Cleanroom LED Panels

- 5. Services Provided with Cleanroom LED Panel Purchases from VCR

- 6. Frequently Asked Questions (FAQ)

1. Role of Cleanroom LED Panel Lighting in GMP Factories

Cleanroom LED panel lights are not just ordinary lighting devices but also play an important role in maintaining the production environment at GMP standards. Choosing the correct type helps ensure operational efficiency, product safety, and compliance during rigorous inspections.

Meeting GMP‑WHO lighting conditions

According to GMP and WHO guidelines, environments that produce pharmaceuticals, food, or cosmetics must have adequate, stable lighting that does not cause eye fatigue. Cleanroom LED panels provide uniform, flicker‑free light with a high Color Rendering Index (CRI), enabling personnel to observe, inspect, and operate more accurately and comfortably.

Reducing cross‑contamination risk and particle generation

Cleanroom LED panels are typically flush‑mounted and integrated into the ceiling so there are no gaps or crevices for dust accumulation. In addition, they do not emit ozone or use cooling fans, thereby reducing turbulent airflow that might lead to cross contamination in cleanrooms.

Improving maintenance and cleaning efficiency

The surface of LED panels is made of tempered glass or acrylic, which is easy to wipe clean with alcohol or specialized cleaning agents. The sealed design also reduces the frequency of cleaning, saving time and labor in regular maintenance.

Optimizing operating costs in GMP factories

LED panel lights have long lifespans (over 50,000 hours) and consume less power than traditional fluorescent lamps while still delivering standard illumination levels. This can significantly reduce electricity and replacement costs in the long run.

Supporting GMP facility approval criteria

Lighting systems are among the items evaluated during GMP audits. Using properly standardized LED panels helps companies score well during facility assessments, thereby shortening the certification time and improving credibility with partners.

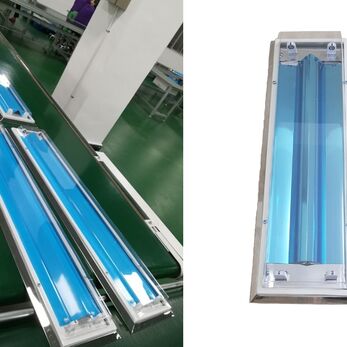

Read more: Comparison of UV and LED lamps in clean rooms: Practical applications

2. Criteria for Choosing GMP‑Standard Cleanroom LED Panels

In a controlled production environment, selecting the right lights affects not only illumination quality but also cleanliness, safety, and GMP compliance. Below are key criteria to consider:

Lighting performance: CRI > 80, color fidelity

A higher CRI means lighting is closer to natural light, helping personnel distinguish colors, read labels, and inspect materials accurately. GMP‑grade panels typically have CRI ≥ 80; some specialized models exceed CRI 90.

No particle emission, no ozone, no flicker

Unlike traditional lighting types, cleanroom LED panels are designed without fans or moving parts, thereby not generating dust or ozone. High‑quality drivers ensure stable, flicker‑free light, reducing eye strain and errors.

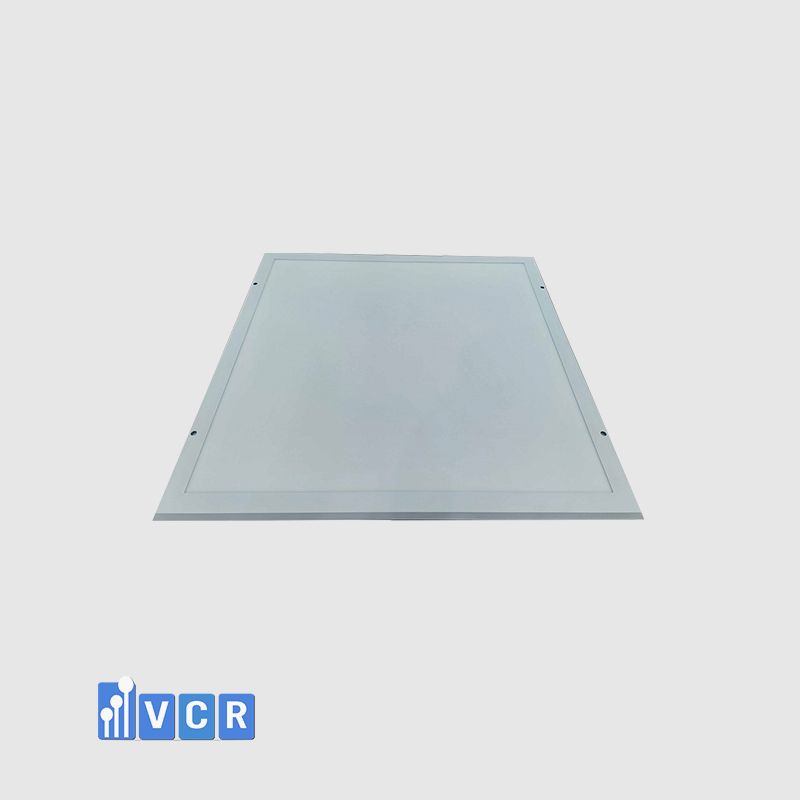

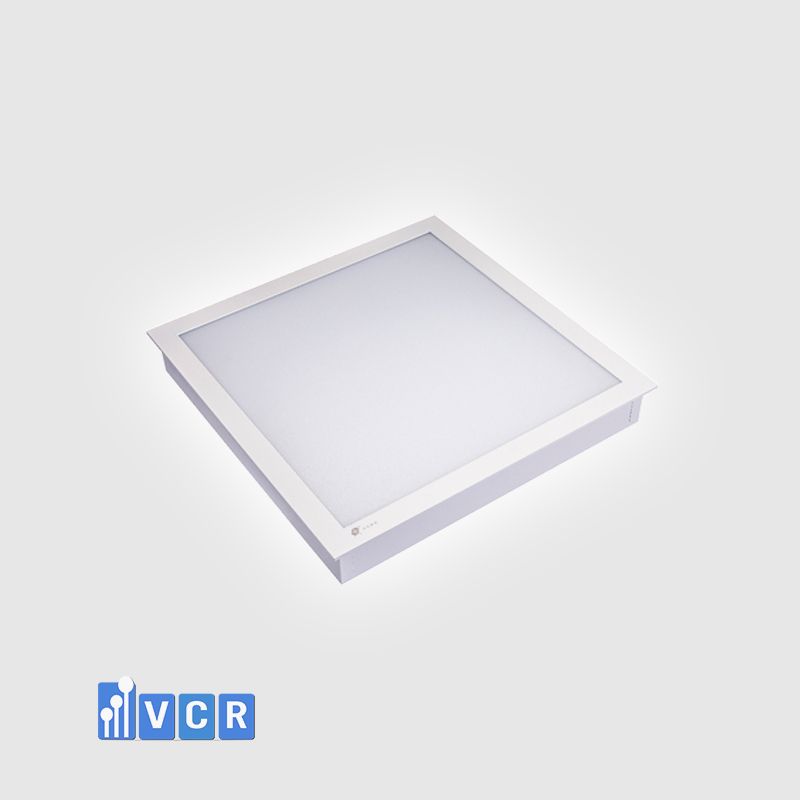

Easy to clean, flat and flush‑mounted design

Particularly in cleanrooms, the lighting surface should be flat, sealed, and mounted flush with the ceiling to avoid gaps that trap dust. Surfaces are typically made of tempered glass or durable acrylic, resistant to chemical cleaning agents.

Corrosion‑ and chemical‑resistant materials

The frame should be made of powder‑coated steel or stainless steel to resist cleaning chemicals. Lighting with an IP65 rating or higher helps prevent dust, moisture, or water ingress—especially useful in areas with humidity or periodic ceiling washing.

Long lifespan (≥ 50,000 hours), energy efficient

High‑efficiency LED technology ensures long operational lifetime, reducing both energy consumption and replacement interruptions.

Below is a comparison between typical LED lights and cleanroom LED panels:

| Criteria | Typical LED Lights | Cleanroom LED Panel |

|---|---|---|

| Design | Uneven, many gaps | Flat, sealed, flush‑mounted |

| CRI | 70–80 | ≥ 80 (GMP standard) |

| Heat / Ozone | May generate | None |

| Cleaning | Hard to wipe, traps dust | Easy to clean, minimal dust accumulation |

| Chemical resistance | Not specialized | Designed for resistance |

| Lifespan | ~30,000 hours | ≥ 50,000 hours |

| Energy efficiency | Average | High |

| GMP compliance | No | Yes |

Read more: Cleanroom LED panel lights: How to choose lux for each cleanliness level

3. Practical Applications Across GMP Industries

Cleanroom LED panels are widely used in industries requiring strict environmental control. Each sector has specific standards for lighting, cleanliness, and cleaning accessibility, which demand appropriate lighting solutions.

Pharmaceuticals

- Lighting requirement: ≥ 500 lux, neutral color temperature (4000K–5000K)

- Panel type: sealed, flush‑mounted, no gaps to minimize particle generation; easy to clean with medical alcohol.

Food Industry

- Lighting requirement: minimum 300–500 lux, natural lighting

- Panel type: IP65 rated, moisture‑resistant LED panels to protect internal electronics from moisture or steam.

Cosmetics

- Requirement: Stable light, no flicker, high color fidelity

- Panel type: CRI > 90 models to provide accurate color rendering—critical for detecting impurities, observing textures and finishes.

| Industry | Lighting Requirement | Suitable LED Panel Type |

|---|---|---|

| Pharmaceuticals | ≥ 500 lux, neutral light | Sealed, flush LED panels |

| Food | 300–500 lux, natural light | IP65 moisture‑resistant LED panels |

| Cosmetics | Stable light, high CRI | CRI > 90, flicker‑free LED panels |

Read more: Navigating FDA and ISO Standards for Clean Room Lighting in Food Manufacturing

4. VCR — Reputable Supplier of Cleanroom LED Panels

When selecting lighting equipment for clean environments, supplier reliability is as important as product quality. With more than 10 years of experience in cleanroom equipment, VCR is proud to serve as a supplier of GMP‑standard LED panels for hundreds of pharmaceutical, food, and cosmetics factories across Vietnam.

Products with international quality certifications

- ISO 9001 for strict production and quality control

- CE, RoHS compliance for safety and environmental friendliness

- Each batch includes CO, CQ, technical drawings, and test reports to support GMP auditing

Lighting design consultation

- VCR’s technical team provides free layout design in CAD for optimal light placement

- Calculates the required illuminance per area: production, packaging, QC, material storage

- Offers layout advice tailored to ceiling height, cleanliness class, and space constraints

Long‑standing partnerships with GMP–WHO factories

- VCR has supplied equipment to major pharmaceutical and functional food manufacturers

- Deep understanding of GMP audit requirements helps clients standardize from the start

Various product options to suit different needs

- Sealed, flush‑mount LED panels for cleanroom ISO classes 5–8

- Suspended or surface‑mount panels for retrofitting in spaces with false ceilings

- IP65 LED panels for humid or high‑moisture zones

Read more: Supplier of GMP‑Standard Cleanroom LED Panel Lights

5. Services Provided with Cleanroom LED Panel Purchases from VCR

Beyond supplying GMP‑standard products, VCR also offers professional after‑sales services, ensuring customers are supported from selection through operation. Every order includes full support to meet cleanroom installation and auditing requirements.

Nationwide fast shipping

- Large stock kept at warehouses in Hanoi and Ho Chi Minh City

- Orders processed and delivered within 24–72 hours depending on location

- Emergency or phased deliveries available for contractors and project owners

Standard cleanroom installation guidance

- Detailed technical drawings and installation videos

- Consultation on the correct mounting positions for various cleanroom classes (ISO 5–8)

- Support to avoid technical errors during lighting system installation

Full CO, CQ documentation

- Each unit is accompanied by a Certificate of Origin (CO) and Certificate of Quality (CQ)

- Additional documents like test reports, material declarations, and maintenance manuals are available for audit submission

24‑month warranty + flexible returns

- Official 2‑year warranty for all panel lights

- 1‑to‑1 exchange within 7 days for manufacturing defects

- Ongoing technical support throughout the product’s lifecycle, even after warranty expiration

Read more: What is Requirements for clean room lighting

6. Frequently Asked Questions (FAQ)

1. How do cleanroom LED panels differ from ordinary LED lights?

A: Cleanroom LED panels are specifically engineered for environments requiring strict control, such as pharmaceutical or food factories. Key differences include:

-

Sealed design with no gaps to prevent dust accumulation

-

No ozone generation, no air turbulence

-

Chemical‑resistant housing, easy to clean

-

Compliance with required IP rating, CRI, and illuminance standards in GMP environments

2. How can one verify if a panel meets GMP standards?

A: Key factors to check include:

-

Existence of CO, CQ, and manufacturer test reports

-

CRI ≥ 80 and stable, flicker‑free light

-

Flush, sealed mounting and easy cleaning design

-

Compliance with IP and chemical resistance requirements

-

Usage in factories already certified GMP/WHO

3. Does VCR provide layout and lighting placement support?

A: Yes. When purchasing LED panels from VCR, customers receive full support including:

-

Lighting layout drawings tailored to the cleanroom

-

Calculations of required lux levels by area: production, packaging, QC, storage

-

Recommendations on model selection based on ceiling height and cleanliness class

If you are looking for GMP‑standard LED panel solutions for pharmaceutical, food, cosmetics factories, or need guidance for cleanroom lighting design, VCR is a reliable partner:

-

Products are in stock and shipped quickly across the country

-

Technical consultations align with GMP/WHO standards

-

Full documentation (CO, CQ) simplifies audit acceptance

-

24‑month warranty ensures peace of mind

Contact us now:

Hotline: 090.123.9008

Email: [email protected]

Website: https://denphongsach.com/

Dat VCR