In cleanrooms, the choice between UV and LED lamps not only affects the quality of light but also determines the effectiveness of disinfection and operational safety. This article helps to clarify the differences in principles, functions and usage standards to choose the appropriate lighting solution for each area.

- 1. Why Choosing the Right Lighting Matters in Cleanrooms

- 2. Overview of UV and LED Lighting Technologies in Cleanrooms

- 3. Comparison: UV vs. LED Lighting in Cleanrooms

- 4. Practical Applications by Industry

- 5. Choosing the Right Light for Your Cleanroom

- 6. Frequently Asked Questions

- 7. Need Help Choosing the Right Cleanroom Lighting? VCR Is Here to Support

1. Why Choosing the Right Lighting Matters in Cleanrooms

In a cleanroom system, lighting selection is not simply about illumination—it directly impacts contamination control, operational safety, and compliance with standards such as GMP, HACCP, and ISO 14644.

Cleanroom lighting serves a dual purpose: illumination and disinfection

- Illumination: Specialized LED lights provide stable, flicker-free lighting that meets required lux levels for various areas such as weighing rooms, packaging lines, or QC labs. Inadequate or uneven lighting can affect task accuracy, environmental control, and worker performance.

- Disinfection: UV lights, especially UV-C, are used to eliminate microorganisms, reducing cross-contamination risks in areas like airlocks, gowning rooms, or sterilization chambers. However, UV must be used with caution as improper exposure can be harmful to humans.

Lighting vs. Disinfection - Different Objectives

Each lighting type serves a distinct purpose:

- LED: Prioritizes lighting efficiency, durability, and energy savings.

- UV: Dedicated to microbial control, not intended for continuous illumination.

Using the wrong type for the wrong purpose can lead to wasted investment, safety risks, or failed contamination control.

Industry-specific Applications

|

Industry |

Cleanroom Lighting Role |

|

Pharmaceuticals |

UV for airlock disinfection, LED for production areas |

|

Food Processing |

Dust-proof LEDs for bottling/filling areas |

|

Cosmetics |

Anti-contamination LED lighting, UV in enclosed packaging areas |

|

Electronics |

Anti-static LEDs only; UV is avoided due to component damage |

Therefore, lighting should never be chosen based on assumptions. It must align with the room's purpose, process requirements, and industry regulations.

See more: Cleanroom Lighting Standards: Are They Mandatory?

2. Overview of UV and LED Lighting Technologies in Cleanrooms

In cleanrooms, lighting must not only meet lux levels but also align with operational goals—from continuous illumination to periodic microbial control. Two dominant technologies are UV and specialized LED lights, each with distinct features and applications.

UV Lighting in Cleanrooms

Operating Principle

UV lamps emit ultraviolet light, particularly UV-C at a wavelength of 253.7nm, which disrupts the DNA of microorganisms, effectively killing bacteria, viruses, and fungi in air and on surfaces.

Common UV Types:

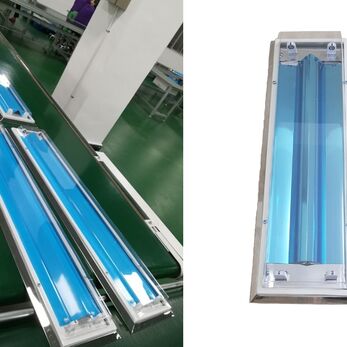

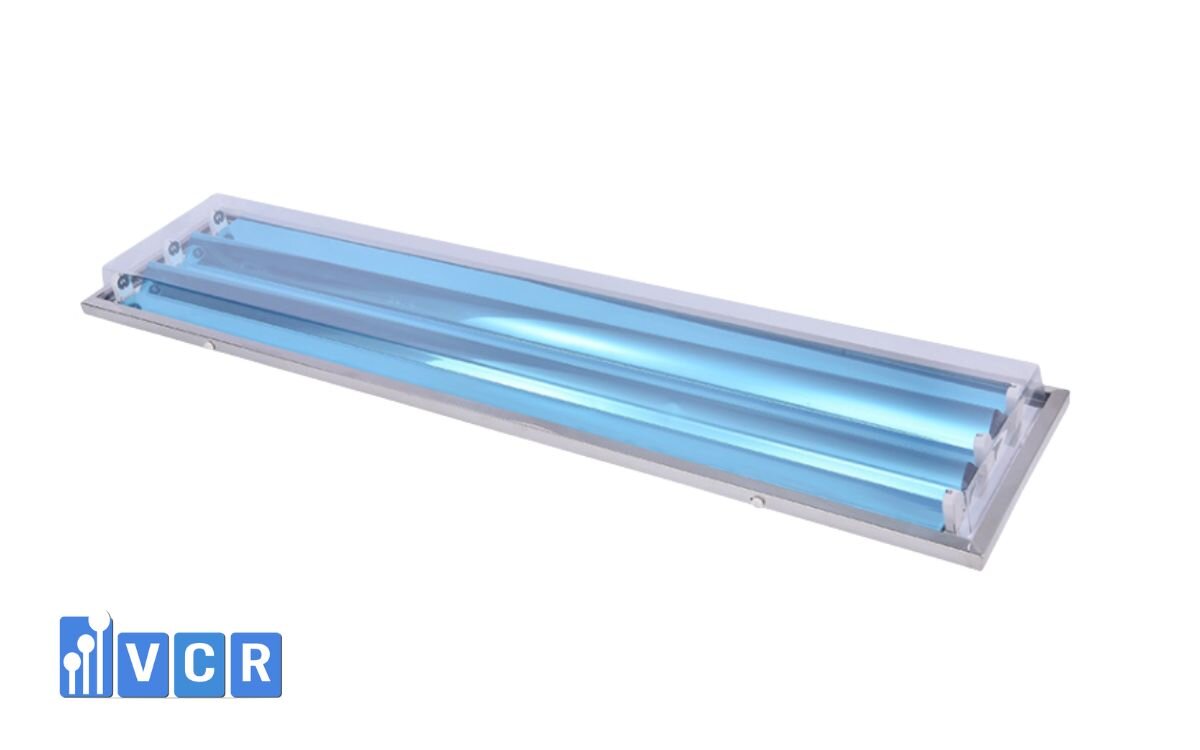

- Mercury UV Lamps: Low-pressure lamps with mercury inside glass tubes, commonly used in HVAC systems and airlocks. Effective but require monitoring for mercury leakage.

- UV LED Lamps: A newer, safer, more compact option with longer lifespan and no mercury.

- Sensor-activated UV Lamps: Automatically turn on when no personnel are detected—ideal for gowning rooms or sterilization chambers.

Primary Use:

Air and surface disinfection in high-risk areas like airlocks and transfer hatches.

Not for use when personnel are present, as UV-C is harmful to skin and eyes.

LED Lighting in Cleanrooms

Operating Principle

LEDs (Light Emitting Diodes) generate light via semiconductor chips, producing a consistent, flicker-free beam with low heat emission. The light spectrum is tailored for cleanroom environments and visual inspection requirements.

Specialized Cleanroom LED Types:

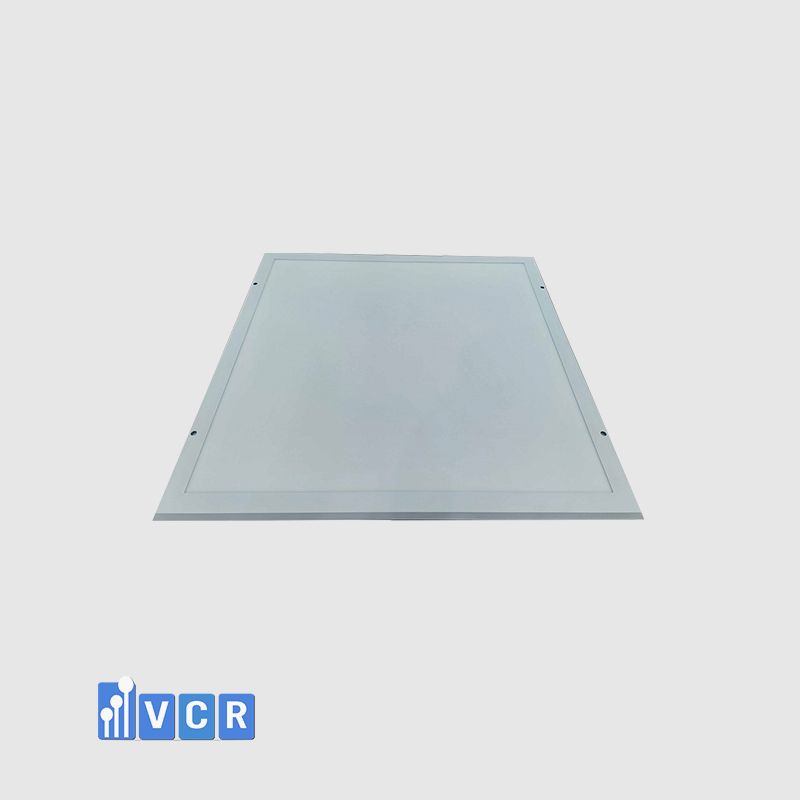

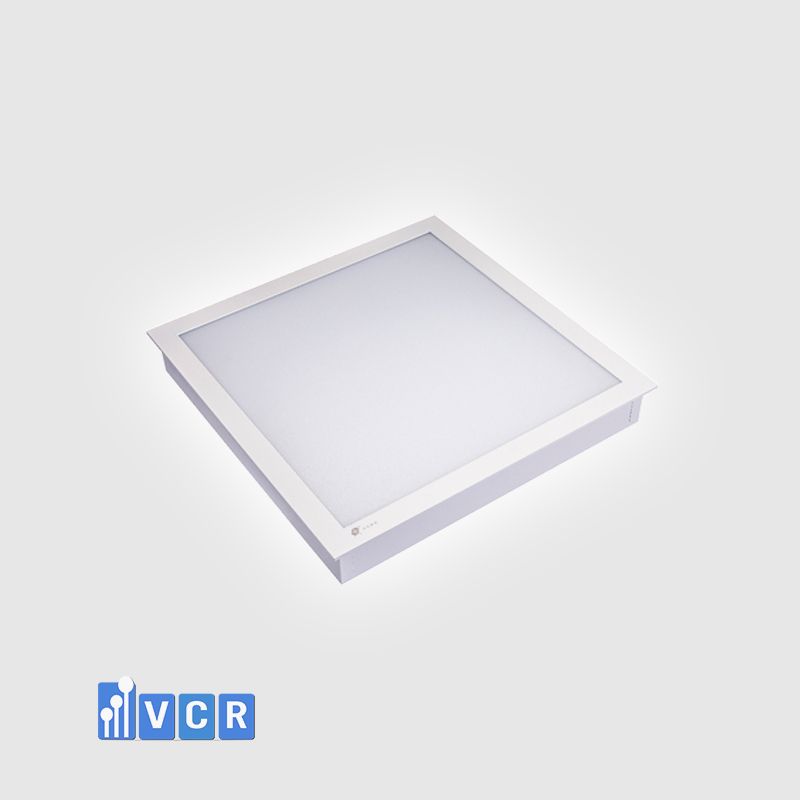

- Recessed LED Panels: Widely used in production and lab areas. Dust-resistant and easy to clean.

- Dust & Anti-static LEDs: Encased in sealed housings, ideal for SMT zones or electronic assembly.

- GMP/ISO-compliant LEDs: Deliver standardized lighting levels (300-500 lux), glare-free and stable.

Primary Use:

Reliable illumination in cleanroom conditions, with minimal maintenance and energy consumption (lifespan 30,000-50,000 hours). Safe for continuous use in occupied areas.

See more: Latest Price List for Cleanroom Lights Used in Food Processing Plants

3. Comparison: UV vs. LED Lighting in Cleanrooms

Both UV and LED lighting play critical roles in modern cleanrooms—but for different goals. Understanding their technical attributes, safety, and operational fit is essential to selecting the right lighting solution.

Comparison Table

|

Criteria |

UV Lighting in Cleanrooms |

LED Lighting in Cleanrooms |

|

Primary Purpose |

Disinfection of air and surfaces |

Illumination of production, packaging, QC areas |

|

Common Use Cases |

Airlocks, gowning rooms, sterilization chambers |

Production lines, packaging zones, weighing areas |

|

Safety for Human Presence |

Not safe during exposure |

Completely safe for continuous use |

|

Average Lifespan |

8,000 - 10,000 hours |

30,000 - 50,000 hours |

|

Energy Efficiency |

Effective but heat-intensive, faster degradation |

Highly efficient, low heat generation |

|

Maintenance Requirements |

Requires scheduled replacement and safety checks |

Minimal maintenance, long operational life |

|

GMP/ISO Compatibility |

Needs strict usage control, off-hours operation |

Easily integrated, compliant with cleanroom standards |

Expert Insight

- UV lighting should be used in a controlled manner, limited to areas requiring periodic disinfection without personnel present.

- LED is the preferred choice for continuous, safe, and energy-efficient illumination, compatible with cleanroom classifications from ISO 5 to ISO 8.

4. Practical Applications by Industry

Each industry has different requirements for lighting, microbial control, and operational standards. The use of UV or LED lights in cleanrooms must be tailored to the intended purpose, production characteristics, and required cleanliness level.

Pharmaceutical Industry (GMP - EU, WHO)

UV lights are typically installed in:

- Airlocks, gowning rooms, and material staging areas for disinfection after working hours to reduce cross-contamination.

- These systems can be integrated with motion sensors for safe operation only when the area is unoccupied.

LED lights are used in:

- Main production areas, compounding rooms, and packaging zones.

- Recessed LED panel lights are preferred due to their dust resistance and compliance with GMP lux requirements (300-500 lux).

- They maintain stable lighting without affecting room temperature or humidity.

Cosmetics & Food Industries (ISO 22716, HACCP)

Cleanroom LEDs are the primary lighting solution because:

- They emit minimal heat, preserving temperature-sensitive products.

- Easy maintenance, moisture resistance, and uniform lighting for areas like filling, packaging, and handwashing zones.

UV lights can be used in:

- Sterilization rooms and enclosed areas such as equipment or packaging material prep zones.

- They should not be installed in main production areas due to safety risks for personnel.

Electronics Industry (ISO 14644 - ISO 5 to ISO 7)

UV lighting is not recommended because:

- UV-C radiation can damage microchips, sensitive circuit boards, and specific plastic components.

- It may interfere with light-based inspection systems.

Anti-static LED lighting is the standard:

- Sealed LED fixtures prevent static discharge and do not flicker.

- Ideal for SMT lines and AOI inspection rooms, ensuring precise, color-consistent illumination.

See more: 8 Crucial Factors to Ponder Before Buying Cleanroom Lights

5. Choosing the Right Light for Your Cleanroom

No single type of lighting fits every cleanroom environment. Selection must be based on operational needs, production characteristics, and the specifics of each area. Below are some practical guidelines to help you make the right choice from the outset:

For continuous, safe lighting → Choose cleanroom LED lights

Best for: main production areas, packaging zones, QC labs, raw material storage.

Why choose LED:

- Stable, flicker-free lighting reduces eye strain.

- No heat emission—maintains optimal environmental conditions.

- Durable, energy-efficient—ideal for 24/7 operations.

Recommended types: recessed LED panels, dust-proof and anti-static models compliant with ISO/GMP lux standards.

For periodic, short-term disinfection → Use controlled UV lights

Best for: airlocks, gowning rooms, material transfer areas, sterilization chambers.

Usage notes:

- Operate only outside of working hours or with motion sensors.

- Install in appropriate locations and at correct dosages to ensure disinfection without safety risks.

Recommended types: industrial-grade UV-C disinfection lamps with timers or occupancy sensors.

For new or GMP-upgraded facilities → Combine LED and UV lighting

Recommended strategy:

- Use LED lighting for all main operational areas to ensure clean, stable illumination.

- Install UV lights in buffer zones or material transfer areas to supplement air filtration systems.

Benefits of combining both:

- Optimized long-term investment.

- Meets both illumination and microbial control requirements.

See more: Choosing the Best Cleanroom Lights for Your Factory

6. Frequently Asked Questions

Should UV lights be used in main production rooms?

Not recommended.

UV-C light can be harmful to skin and eyes with prolonged exposure. In areas where personnel work continuously, LED lighting is the safer choice. UV lights should only be used after hours or in isolated, unoccupied spaces.

Do LED lights meet GMP lighting requirements?

Yes.

Many LED panel models are specifically designed for cleanroom use and comply with GMP/ISO 14644 requirements, including:

- 300-500 lux depending on the area

- Glare-free, flicker-free performance with no secondary dust generation

- Sealed housings for easy cleaning and contamination control

Is UV LED better than mercury-based UV?

It depends on the application.

- UV LED: Safer, mercury-free, longer lifespan—ideal for small or enclosed areas needing targeted disinfection.

- Mercury UV: Lower cost and higher intensity, but requires safety monitoring for leaks and periodic replacement.

How often should UV lamps be replaced in cleanrooms?

Typically every 8,000 to 10,000 hours, or based on internal maintenance schedules and disinfection efficiency tests.

Regular checks should confirm:

- UV-C wavelength remains effective at 253.7nm

- No leakage or bulb damage

- Operation under appropriate environmental conditions (not overly humid or hot)

7. Need Help Choosing the Right Cleanroom Lighting? VCR Is Here to Support

Choosing the right cleanroom lighting affects not only visibility but also production efficiency, microbial control, and GMP/ISO compliance.

If you're wondering:

- Should you use LED or UV lighting in your airlock?

- What is the installation cost for a cleanroom lighting system?

- Can UV lights be integrated with motion sensors for safety?

Contact VCR’s technical team for a free consultation and customized lighting solutions based on your industry, cleanliness class, and budget.

Hotline: 090.123.9008

Email: [email protected]

Website: https://denphongsach.com/

Diep VCR