Lux is not only a technical number but also directly determines the accuracy of product testing, infection control and GMP - ISO compliance. So cleanroom LED panel lights: How to choose lux for each clean level to ensure production quality and meet international standards?

- 1. What is lux in a cleanroom? Why is choosing the right lux level important?

- 2. Recommended lux levels by cleanroom classification (ISO 5 - 8)

- 3. How to select LED panel lights based on required lux

- 4. Key features of LED panel lights for cleanrooms

- 5. Recommended LED Panel Lights by Cleanroom Classification

- 6. Frequently Asked Questions about Cleanroom LED Panel Lights

- 7. Need Help Selecting the Right Cleanroom LED Panel Lights?

1. What is lux in a cleanroom? Why is choosing the right lux level important?

Lux is a unit of illuminance that measures the amount of light falling on a specific surface. Specifically, 1 lux = 1 lumen/m². In cleanroom environments, the lux level plays a critical role as it directly impacts production quality and compliance with standards.

Here are three key reasons why selecting the appropriate lux level for each cleanroom class is essential:

1. Ensures product inspection quality

In areas such as filling rooms, laboratories, or packaging zones, insufficient lighting may cause operators to overlook small defects like dust, cracks, or packaging errors. A proper lux level significantly enhances visual inspection accuracy, especially in industries like pharmaceuticals and cosmetics.

2. Reduces the risk of contamination and cross-contamination

Poor lighting increases the risk of “blind spots” during cleaning, allowing bacteria or micro-particles to remain undetected. Choosing the correct lux level helps improve contamination control, particularly in high-sterility zones like ISO 5 or ISO 6 cleanrooms.

3. Compliance with GMP, ISO 14644, and audit requirements

Standards such as GMP-EU and ISO 14644 clearly specify minimum lighting levels for various cleanroom zones. If lighting is insufficient, the facility may fail audits, impacting its ability to produce or export regulated products.

Therefore, selecting LED panel lights is not only about aesthetics or energy savings but is an essential part of maintaining a compliant cleanroom environment.

2. Recommended lux levels by cleanroom classification (ISO 5 - 8)

In cleanroom design, each ISO classification has specific lux requirements to ensure accurate inspection, production, and cleaning processes. The table below outlines recommended lux levels per ISO class:

|

Cleanroom Class (ISO) |

Typical Application Areas |

Recommended Lux Level |

|

ISO 5 |

Sterile rooms, aseptic filling zones |

750 - 1000 lux |

|

ISO 6 |

Weighing areas, microbiology labs |

500 - 750 lux |

|

ISO 7 |

Compounding, packaging of semi-finished goods |

300 - 500 lux |

|

ISO 8 |

Change rooms, clean corridors |

200 - 300 lux |

Important Notes:

- Higher lux levels allow better control over contaminants such as dust and microbes.

- Lux should be adjusted depending on the industry:

- Pharmaceuticals and cosmetics: Prefer higher lux levels for quality control.

- Electronics and semiconductors: Lower lux levels may suffice in areas without visual-critical tasks.

Choosing the correct lux level supports both production efficiency and compliance with international standards like ISO 14644, GMP-EU, and HACCP.

See more: Latest price list of Clean room lights used in electronics factories

3. How to select LED panel lights based on required lux

To ensure your cleanroom meets required lighting levels, it’s essential to accurately calculate the number and type of LED panel lights to be installed. Follow these three simple steps:

Step 1: Determine the area to be illuminated

Measure the length and width of the area to get the surface area in square meters.

Example: A cleanroom measuring 5m x 4m → area = 20 m²

Step 2: Define the target lux level according to ISO class

Refer to the lux table above.

Example: For ISO 7, select 500 lux as an average value.

Step 3: Calculate the number of LED panels required

Use the formula below:

Total lumens required = Lux level x Area (m²)

Number of lights = Total lumens / Lumen output per light

Where:

- Lumen = the amount of light emitted by a fixture

- A standard 36W cleanroom LED panel typically emits about 2,500 lumens

Example calculation:

ISO 7 cleanroom, 20 m², target 500 lux →

Total lumens = 500 x 20 = 10,000 lumens

Number of lights = 10,000 / 2,500 = 4 LED panels

See more: Key Considerations in Designing Cleanroom Lighting Systems

4. Key features of LED panel lights for cleanrooms

Not all LED lights are suitable for cleanroom environments. Cleanroom LED panels must meet strict technical criteria to prevent particle generation, enable easy cleaning, and maintain consistent light levels over time.

Here are the most important features:

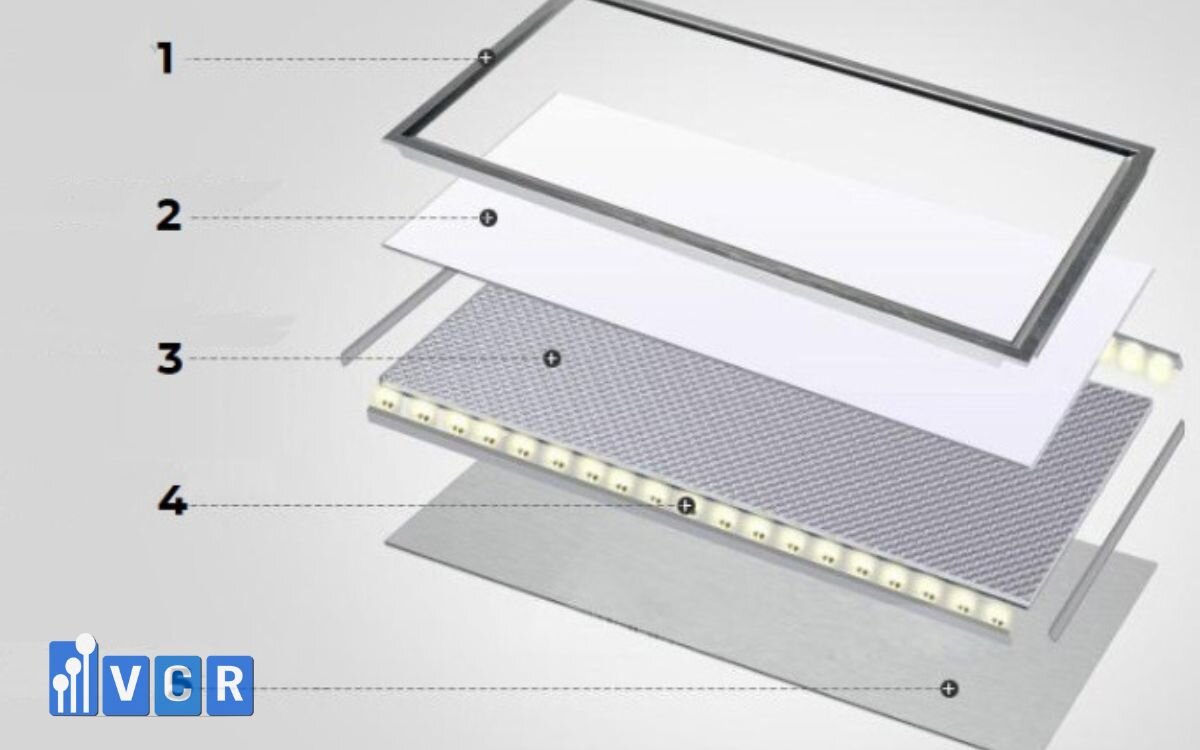

1. Sealed design - prevents dust generation

LED panels should be installed flush with ceiling panels or recessed to avoid gaps that collect dust or harbor microbes.

A fully enclosed design (IP54 or higher) prevents airborne particles from escaping or entering the fixture.

2. Corrosion-resistant housing - easy to clean

Housing should be made of powder-coated aluminum or stainless steel, which resists oxidation from strong cleaning agents.

Diffusers are typically made of tempered glass or anti-glare PMMA for durability and easy cleaning with alcohol or disinfectants.

3. High color rendering index (CRI ≥ 80)

CRI (Color Rendering Index) indicates how accurately colors are perceived under a light source.

For tasks involving inspection, weighing, or formulation, incorrect lighting may lead to quality issues. Use CRI ≥ 80, or even CRI ≥ 90 for applications in pharmaceuticals or cosmetics.

4. Long lifespan ≥ 50,000 hours

High-quality LED panels can operate continuously for more than 5 years, minimizing maintenance and replacement costs.

Preferably, choose lights with external drivers or built-in protections (over-voltage, thermal cutoff) to withstand demanding cleanroom environments.

See more: 8 Crucial Factors to Ponder Before Buying Cleanroom Lights

5. Recommended LED Panel Lights by Cleanroom Classification

Each ISO cleanroom class has different requirements for lighting intensity, particle control, and cleaning frequency. Therefore, choosing the right LED panel lights for each classification helps optimize costs, ensures operational efficiency, and facilitates compliance during audits.

Below are suggested lighting configurations based on common ISO classes:

ISO 5 - ISO 6: Lights for sterile zones, filling areas, pharmaceutical weighing rooms

- Size: 600x600mm or according to standard ceiling grid

- Power: 40W - 48W

- Luminous flux: ≥ 3,000 lumens

- CRI: 90 or higher - supports accurate color inspection of drugs and solutions

- Features: Fully flush design, high dust protection, anti-glare

- Applications: Pharmaceutical production, microbiology, critical manufacturing zones

ISO 7 - ISO 8: Lights for packaging areas, hallways, and gowning rooms

- Power: 36W - energy efficient

- Luminous flux: Approximately 2,500 - 2,800 lumens

- CRI: Minimum 80

- Recommended feature: External driver for easier maintenance and improved durability under frequent switching

- Applications: Supporting areas, clean corridors, material prep rooms

Specific to pharmaceutical and cosmetics sectors:

- Select lights with ISO 14644-1 certification or equivalent

- Prefer models with certified particle emission reports, suitable for GMP and ISO 22716 audits

- In areas with camera surveillance, choose neutral white light (4000-5000K) to reduce glare

See more: Latest Price List for Cleanroom Lights Used in Food Processing Plants

6. Frequently Asked Questions about Cleanroom LED Panel Lights

- How many lux are needed for an ISO 7 cleanroom?

ISO 7 cleanrooms typically require between 300-500 lux, depending on the task:

- 500 lux: for detailed tasks like packaging or manual inspection

- 300 lux: sufficient for storage or cleanroom corridors

- How are cleanroom LED panels different from regular LED lights?

Cleanroom LED panel lights are specially engineered to meet strict contamination control standards:

- Sealed design that prevents dust emission

- Corrosion-resistant materials, compatible with strong cleaning agents

- Easy to clean surfaces without dust-trapping crevices

- Is a high CRI mandatory for cleanroom lighting?

Not all areas require high CRI, but for industries such as:

- Pharmaceuticals, cosmetics, and inspection zones → CRI ≥ 80 or 90 is recommended to ensure accurate color recognition and quality control.

- Can regular recessed LED lights be used in cleanrooms?

It is not recommended. Regular residential or commercial LED lights:

- Are not dust-sealed, often have gaps that trap contaminants

- Lack material certifications for cleanroom environments

- Are prone to failure under high humidity or frequent switching conditions

7. Need Help Selecting the Right Cleanroom LED Panel Lights?

Choosing the wrong light fixtures not only affects brightness but may also cause your cleanroom to fail ISO/GMP audits. Let the VCR technical team support you from A to Z:

- Advise on appropriate lux levels for each cleanroom zone

- Calculate optimal number of lights

- Provide detailed layout designs and pricing

Contact us now for free consultation:

Hotline: 090.123.9008

Email: [email protected]

Website: https://denphongsach.com/

Diep VCR