Cleanroom LED panel lights are a specialized lighting solution for SMT areas — zones where high standards of cleanliness, brightness, and precision are required. With dust-proof, anti-static design and stable illumination, LED panels help maintain ISO standards, ensure assembly quality and protect micro-circuits.

- 1. What is a cleanroom LED panel light?

- 2. Why does an SMT area need dust-proof dedicated LED panel lights?

- 3. Criteria for selecting LED panel lights for SMT cleanrooms

- 4. Reputable supplier of LED panel lights for SMT cleanrooms in Vietnam

- 5. Pricing and support policy

- 6. Frequently Asked Questions (FAQ)

1. What is a cleanroom LED panel light?

A cleanroom LED panel light is a type of lighting fixture designed for environments with strict control over dust particles, bacteria and static electricity - such as cleanrooms in electronics, pharmaceuticals, food factories and especially SMT zones.

Unlike ordinary domestic LED lights, cleanroom LED panels feature a sealed structure, smooth flat surface and use anti-static or dust-resistant materials. This design helps prevent dust generation, is easy to clean, and does not compromise the cleanliness of the working environment.

In cleanrooms, LED panel lights not only ensure adequate illumination for equipment operation and precise manipulation, but also contribute to maintaining ISO cleanliness levels thanks to their ability to minimize particles released into the air.

Role in SMT areas

In SMT (surface‐mount technology) areas - where parts are mounted onto printed circuit boards (PCBs) - incredibly stable and precise lighting is required. Any fluctuation in brightness or color rendering index (CRI) can cause deviations during inspection, soldering or assembly.

Therefore, cleanroom LED panel lights play a crucial role in:

-

Providing uniform light, no glare, supporting quality inspection of solder joints

-

Minimizing dust or static discharge risk, preventing circuit shorts or micro-circuit damage

-

Maintaining stable working conditions, reducing manual error in the SMT production line

Technical requirements in SMT zones

To meet the specific production environment of SMT, LED panel lights must satisfy certain technical requirements:

-

Sealed design, dust protection (IP40 or higher)

-

Use anti-static materials, ensuring safety for sensitive micro-circuits

-

CRI ≥ 80, for accurate light rendering

-

Stable correlated color temperature (CCT), typically 5000 K to 6000 K, to reduce eye fatigue during long shifts

Read more: Latest price list of Clean room lights used in electronics factories

2. Why does an SMT area need dust-proof dedicated LED panel lights?

The SMT production environment is extremely sensitive to dust and electrostatic discharge (ESD).

In SMT zones - where main steps include solder paste printing, component placement, reflow soldering - precision is extremely high and components are small, thin and sensitive to external factors.

In this environment, fine dust or static electricity can seriously affect product quality:

-

Dust may adhere to the PCB, causing soldering defects or short circuits

-

Static discharge may randomly occur (ESD), damaging ICs, chips, transistors…

Thus, lighting systems - including LED panel lights - must also meet cleanroom standards: no particle generation, no static discharge, and no lighting fluctuation.

The harms when using non-standard lights

Using inappropriate LED lights in SMT areas can lead to many risks:

-

Particle generation from the light surface or micro-gaps, contaminating the cleanroom environment

-

Uneven lighting or wrong color temperature, causing inspection errors and increasing defect rates

-

Lack of static control, increasing risk of component damage during handling

Moreover, lacking proper technical standards can make maintenance and replacement difficult and impact production schedule.

Required standards to comply

To ensure suitability for SMT production, cleanroom LED panel lights must comply with some standards:

| Standard | Purpose |

|---|---|

| ISO Class (ISO 14644) | Ensures the light is suitable for the cleanroom class (Class 7 – Class 5) |

| RoHS | Ensures no harmful substances, environmentally friendly and safe for SMT production |

| Industrial lighting standards (CRI, CCT) | Ensures stable illumination, high color rendering for accurate inspection |

| ESD standard | Reduces risk of static discharge impacting sensitive micro-circuits |

Choosing the right cleanroom LED panel light not only helps maintain the production environment’s standards, but also enhances product quality and reduces defects in the SMT line.

Read more: Demystifying the Difference: Cleanroom LED Panel Lights vs. Ordinary Options

3. Criteria for selecting LED panel lights for SMT cleanrooms

When choosing LED panel lights for SMT production areas, companies need to consider not only illumination factors, but also cleanliness, stability and compatibility with industrial standards. Below are important criteria:

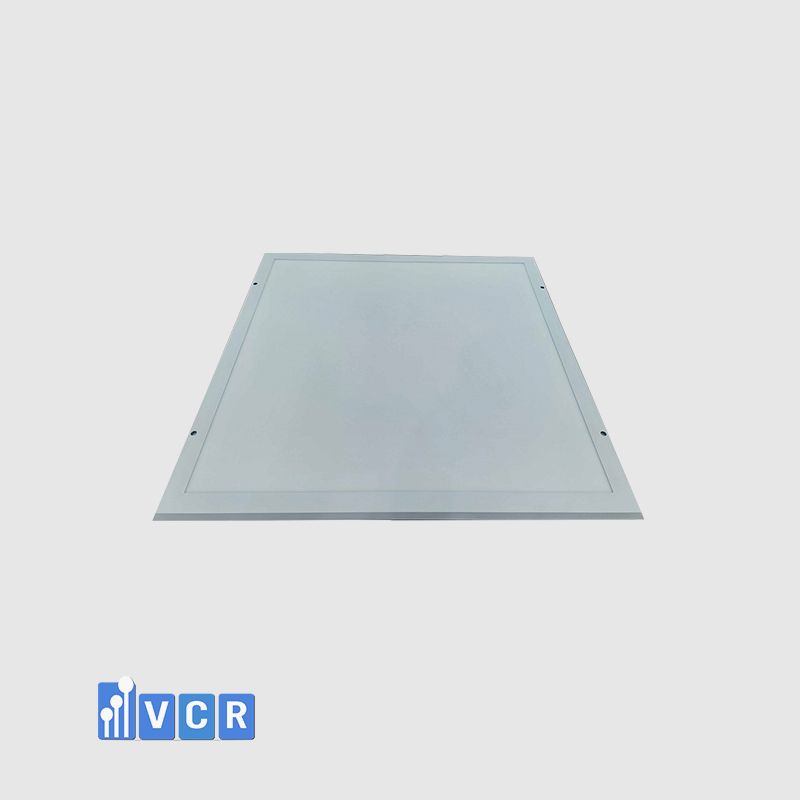

Meeting cleanroom ISO standards: LED panels used in cleanrooms must fulfil ISO 14644-1 - the international standard governing particle counts in the air for each cleanroom class. The light must be designed such that:

- No particle generation during usage

- No disruption to cleanroom air flows (HVAC, HEPA)

- Suitable for cleanroom classes from Class 7 to Class 5 - commonly applied in SMT areas

Sealed, dust- and bacteria-proof design: The structure must ensure full sealing (continuous gasket, no gaps) to:

- Prevent dust penetration into the lamp and shorts

- Avoid bacteria accumulation and allow easy cleaning

- Improve maintenance efficiency and reduce downtime when changing lamps

High color rendering index (CRI), stable illumination: SMT areas require LED panel lights with CRI of 80 or higher, to:

- Clearly distinguish component colours and solder joints

- Minimize errors during visual inspection

Additionally, the illumination must be flicker-free and brightness stable, especially important for automated optical inspection (AOI) cameras.

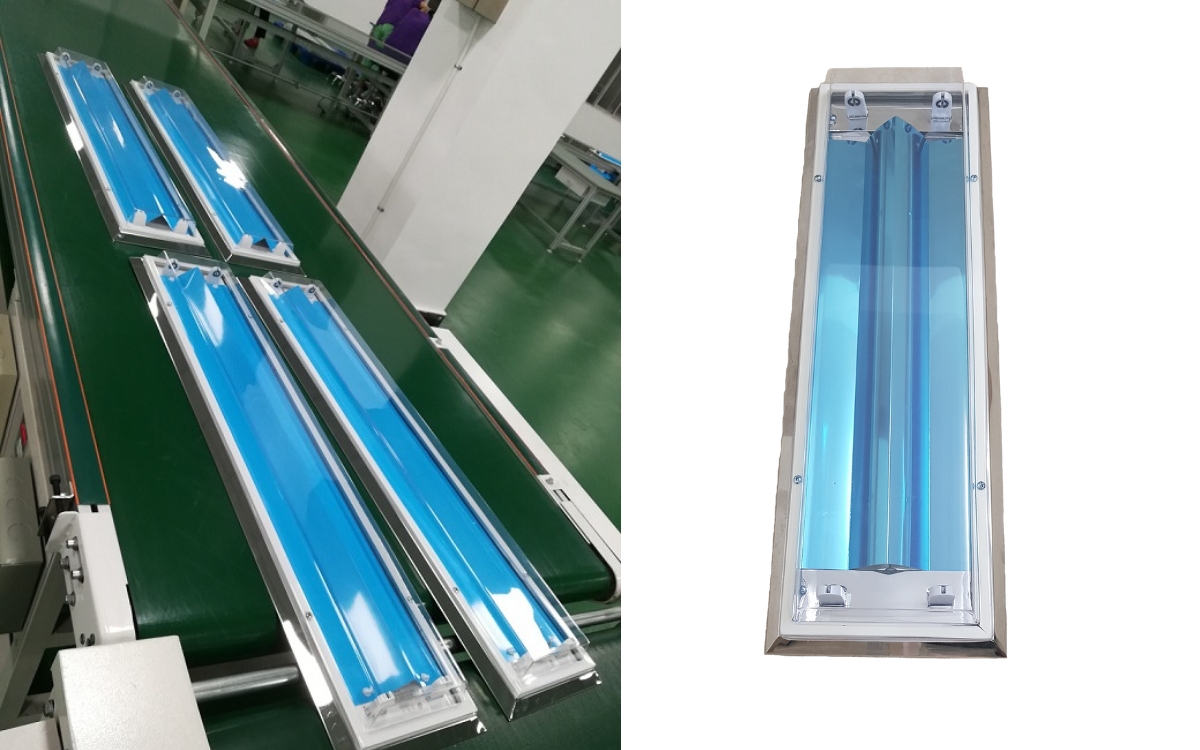

Surface materials: anti-static mica or tempered glass: The diffuser panel should use:

- Anti-static mica: reduces ESD generation, safe for PCBs

- Tempered glass: protects the LED chips inside, increases lamp lifespan

These materials also help achieve uniform light distribution, no glare, suitable for long hours of continuous operation.

Long lifespan, energy-efficient, easy maintenance: A good cleanroom LED panel light should have:

- Lifespan ≥ 30,000 hours, reducing replacement cost

- High luminous efficacy (≥ 100 lm/W), saving energy for the factory

- Module or separate driver design, easy to replace components when needed

Selecting the correct LED panel not only ensures the SMT production environment meets standards, but also helps optimize operational cost and improve production efficiency.

Read more: What is Requirements for clean room lighting

4. Reputable supplier of LED panel lights for SMT cleanrooms in Vietnam

Selecting an appropriate LED panel light for SMT areas depends not only on technical specifications, but also on choosing a reputable supplier who deeply understands the electronics industry - where “clean” and “stable” are minimum requirements.

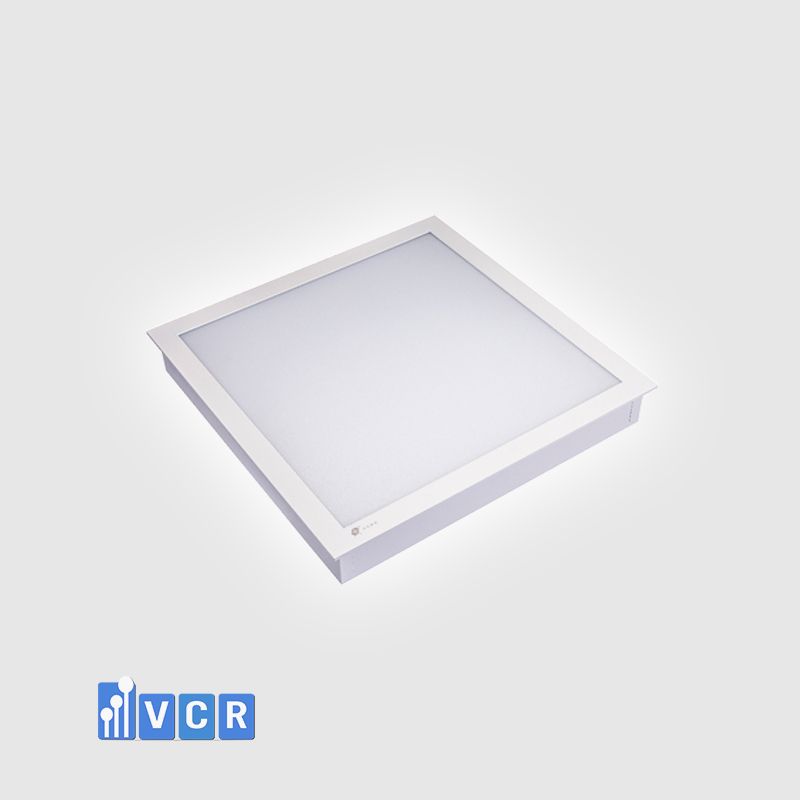

VCR – Trusted partner of electronic manufacturing factories

VCR is a leading provider of clean-room equipment in Vietnam, especially in sectors such as:

-

SMT – electronics assembly

-

EMS – electronic manufacturing services

-

PCB, IC, sensor module manufacturing…

With more than 10 years of experience, VCR not only supplies equipment but also provides comprehensive lighting solutions for cleanrooms, ensuring: -

Optimised lighting layout for SMT zones

-

Compliance with ISO Class and inspection requirements via AOI, SPI, XRAY…

Advantages of cleanroom LED panels supplied by VCR

International standard products (ISO, CE, RoHS)

LED panels distributed by VCR are produced under strict quality control processes, with major certifications such as:

- ISO 9001 / ISO 14644

- CE – European safety standard

- RoHS – Free of hazardous substances, safe for SMT production environment

Lighting design support for cleanroom layout

VCR’s technical team will:

- Survey the actual cleanroom layout

- Calculate number, power and optimal installation positions

- Ensure lighting meets operation and AOI inspection requirements

Dedicated technical service and clear warranty

-

Provide 1-on-1 consultation by cleanroom experts

-

Guidance on correct installation process to avoid compromising cleanroom class

-

Warranty policy 12-36 months, fast technical support throughout use

Read more: Where you should buy Cleanroom Lights

5. Pricing and support policy

When investing in lighting systems for SMT cleanrooms, cost and support policy are important criteria. VCR offers a diverse range of LED panel models, together with transparent after-sales support - suitable for large and small scale projects.

Price segments by standard size

The price of cleanroom LED panel lights depends on size, power and accompanying standards. Some common models include:

-

Size: 600 × 600 mm → 36 W – 48 W, for T-bar cleanroom ceiling

-

Size: 300 × 1200 mm → 40 W – 60 W, for large SMT areas

-

Size: 600 × 1200 mm → 60 W, for full-line illumination

Note: Price may vary depending on required ISO class, anti-static materials or integrated driver.

Flexible configuration options

Customers can choose based on usage needs:

-

Mounting type: recessed T-bar, suspension cable, surface mounted

-

Driver types: standard driver, DALI (smart lighting control), 0-10 V or PWM dimming

-

Custom lighting: colour temperature 5000 K or 6000 K, glare control UGR < 19

All products are technically inspected and cleanroom-packaged before delivery.

Technical support and delivery policy

VCR commits to accompany customers through the entire product lifecycle with clear policies:

-

Free technical consultation based on factory layout

-

Exchange within 7 days if product does not meet committed specs

-

Warranty 12-36 months, includes warranty sticker, code and installation guideline

-

Nationwide delivery, installation support in industrial zones on request

In addition, for large orders or batch projects, VCR supports Excel-based quotation, with labor cost separated to facilitate budgeting.

Read more: Choosing the Best Cleanroom Lights for Your Factory

6. Frequently Asked Questions (FAQ)

Q: Do cleanroom LED panel lights need certifications?

A: Yes. When used in a cleanroom - especially SMT areas - LED panel lights must have certifications such as:

-

ISO Class: matching the cleanroom class (Class 7 – Class 5)

-

ESD Safe: protecting components from static discharge

-

RoHS / CE: ensuring safety, no harmful substances

These certifications help ensure the light fits the strictly controlled environment and doesn’t generate particles or interfere with micro-circuits.

Q: What power of LED panel light is suitable for the SMT area?

A: It depends on the layout, work area size and ceiling height. Typical power ranges for SMT zones:

-

36W – 48W for working areas

-

54W – 60W for larger production areas requiring stronger illumination

White light at 6000 K is commonly used because it gives clear visibility and reduces eye fatigue during long-hour operations.

Q: Can LED panel lights be installed in aluminum cleanroom ceilings?

A: Yes. LED panels offered by VCR are designed to work with many standard cleanroom ceiling systems:

-

Standard T-bar ceilings

-

Closed aluminum ceilings

-

Surface mount or suspension via cable with accessories included

Choosing the appropriate mounting method will help optimise airflow circulation and maintain cleanroom integrity.

Q: Are the lights covered by warranty?

A: Yes. All cleanroom LED panel lights supplied by VCR are covered by a clear warranty policy:

-

12-36 months depending on the model and driver type

-

Technical support throughout usage

-

Warranty sticker, serial code and installation guideline included

If you are seeking a specialised lighting solution for your SMT area, do not let sub-standard choices affect your productivity and product quality.

VCR commits to supplying:

-

Cleanroom LED panel lights meeting international standards

-

Free technical consultation, on-site factory survey

-

Quick, clear quotation and product demo

Contact us now:

Hotline: 090.123.9008

Email: [email protected]

Website: https://denphongsach.com/

Dat VCR