Lighting in electronics factories not only serves vision but also helps control contamination, static electricity and limit errors in production. Specialized cleanroom lights such as LED panels or anti-static lights are designed with smooth surfaces, dust-proof, heat-free, and meet standard illuminance to support precise operations.

- 1. Overview of Lighting Requirements in Electronics Manufacturing Plants

- 2. Common Types of Cleanroom Lighting for Electronics Facilities

- 3. Latest 2025 Price List for Cleanroom Lighting

- 4. Factors Affecting Cleanroom Light Pricing

- 5. Recommended Lighting Selection by Production Area

- 6. VCR's Customer Support & Consultation Policy

- 7. Frequently Asked Questions About Cleanroom Lights

- 8. Contact Us Now - Get Tailored Advice & Accurate Quotations for Your Factory

1. Overview of Lighting Requirements in Electronics Manufacturing Plants

1.1 Role of Lighting Systems in Electronics Factories

Lighting in electronics factories goes beyond ensuring visibility. In environments where microelectronic components are produced—where dust control, static electricity, and cross-contamination are critical—lighting systems play essential roles in:

- Contamination control: Cleanroom lights (e.g., LED panels, anti-static lights) are designed with smooth, dust-free surfaces that don’t generate heat or disperse airborne particles.

- Ensuring proper illumination (lux levels): Illumination directly affects the accuracy of tasks such as PCB assembly, micro-defect inspection, or reading small component markings.

- Reducing visual errors: Poor or uneven lighting can lead to operational mistakes, reduced product quality, and eye fatigue among workers.

1.2 Key Lighting Standards in the Electronics Industry

- ISO 14644

This international standard for cleanrooms regulates the maximum allowable number of airborne particles. Lighting must not disrupt airflow or generate secondary dust. Flush-mounted, sealed lights are mandatory. - IPC-A-610

The standard for electronic assembly acceptability (e.g., PCBs). During micro-defect inspections or soldering checks, illuminance requirements can reach 1000-1500 lux. Lighting must be stable, uniform, and flicker-free. - GMP and ESD Requirements

- GMP (Good Manufacturing Practice): For electronics used in medical or defense industries, GMP mandates easy-to-clean lighting that doesn’t cause electromagnetic interference.

- ESD (Electrostatic Discharge): Lighting should include anti-static properties or at least minimize surface charge buildup to prevent damage to sensitive components.

Proper lighting in electronics manufacturing enhances productivity and is critical to quality control and cleanroom compliance. Choosing the right light fixtures and complying with ISO 14644, IPC-A-610, and ESD/GMP standards is essential for reliable, certified operations.

2. Common Types of Cleanroom Lighting for Electronics Facilities

In electronic production zones, especially in areas like SMT rooms, testing labs, or sensitive component areas, selecting the appropriate lighting solution is vital to maintaining product quality and cleanroom compliance.

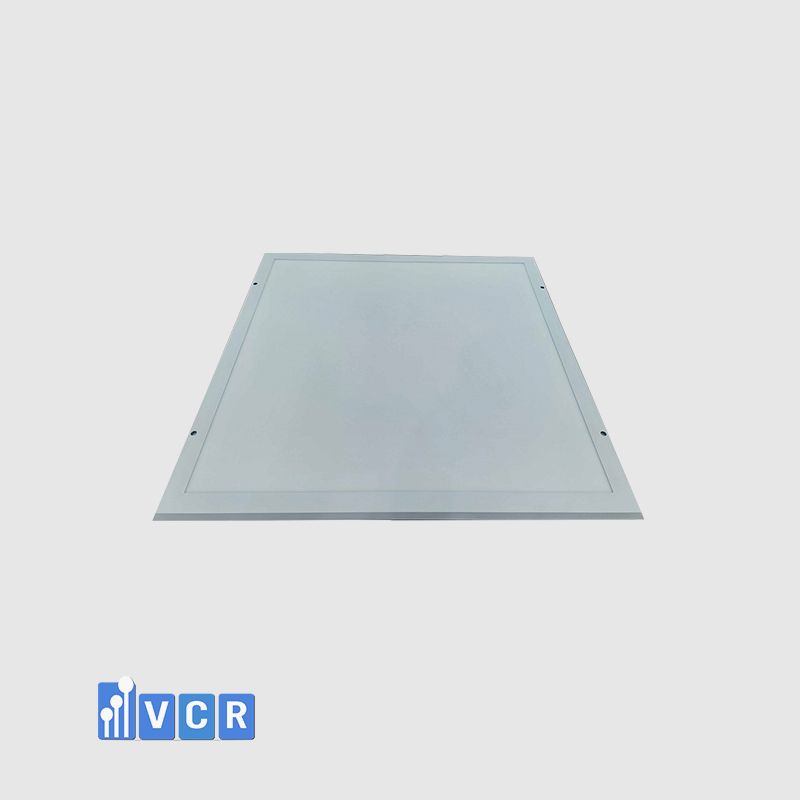

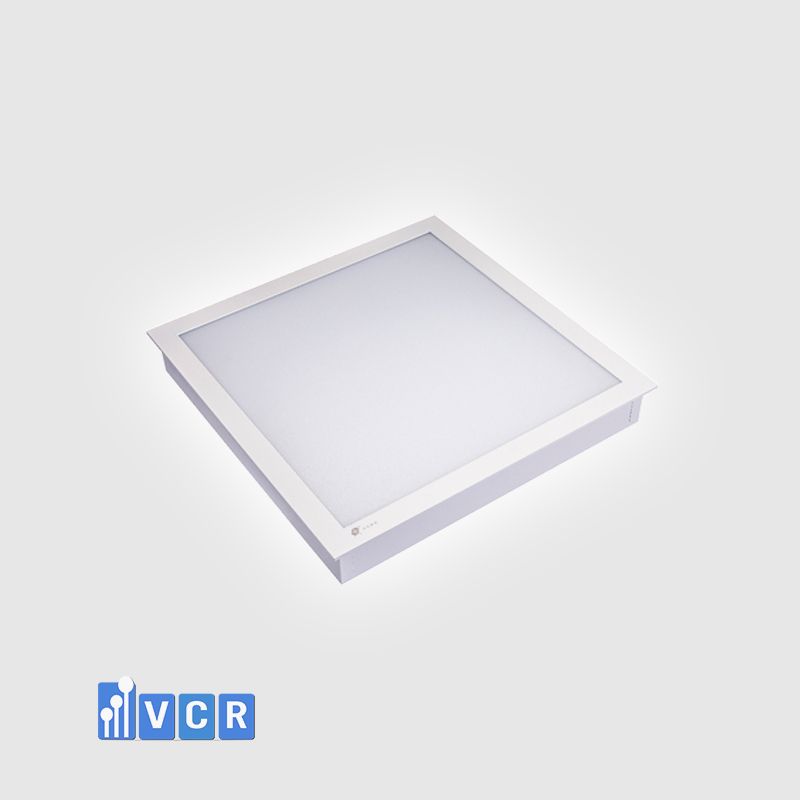

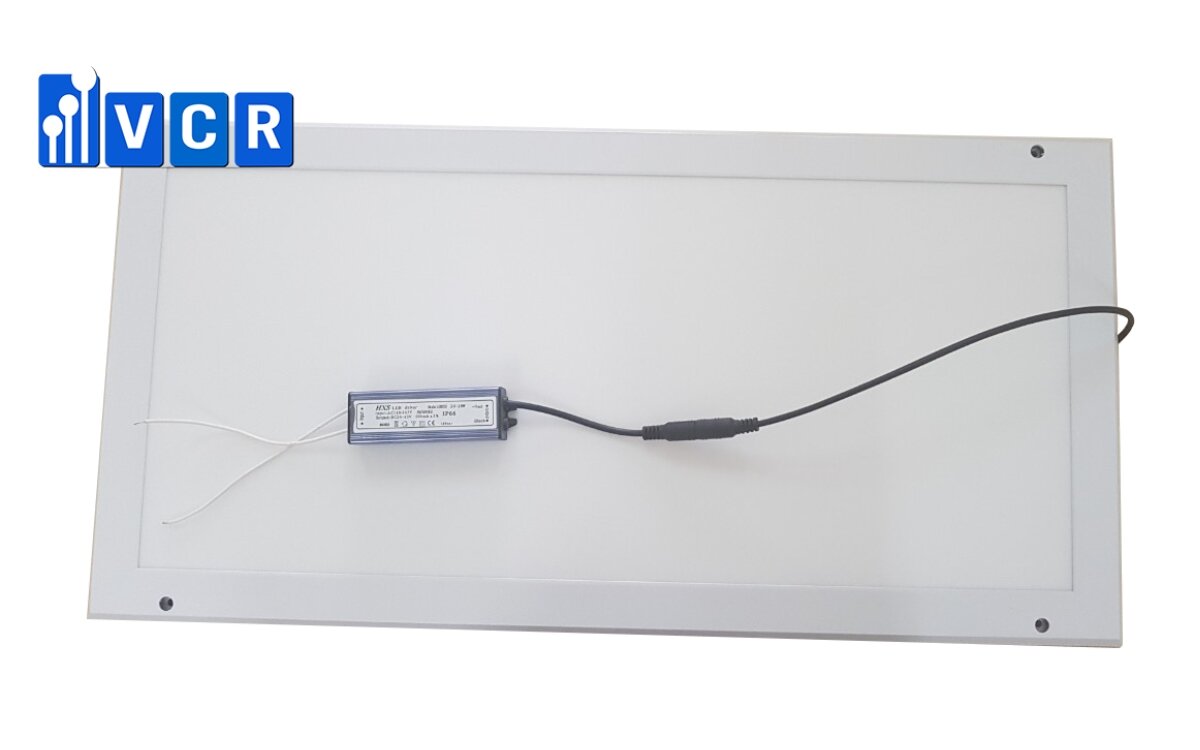

2.1 LED Panel Cleanroom Lights

- Features: Recessed ceiling mount, flat surface design, diffused non-glare lighting. Housings are usually made of powder-coated aluminum or anti-corrosion coated steel.

- Advantages: Low dust generation, easy to clean, non-intrusive to airflow patterns.

- Primary Use: SMT lines, QC rooms, metrology labs—areas requiring uniform and stable lighting.

2.2 Surface-Mounted LED T5/T8 Lights

- Features: Uses T5 or T8 LED tubes, surface-mounted on walls or ceilings, easy to install and maintain.

- Advantages: Cost-effective, energy-efficient, easy to service.

- Primary Use: Hallways, changing rooms, support areas with lower cleanliness requirements.

2.3 IP65 Dust & Water-Resistant Lights

- Features: IP65 rating—fully dustproof and protected against low-pressure water jets. Sealed casing resists moisture and chemical vapors.

- Advantages: Highly durable in harsh environments; suitable for frequent cleaning.

- Primary Use: High-humidity zones, component washing areas, chemical processing rooms.

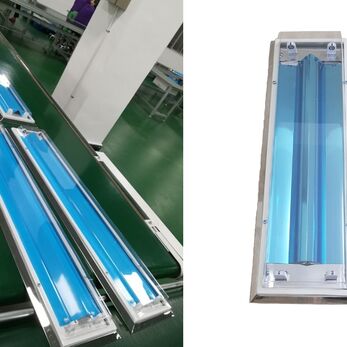

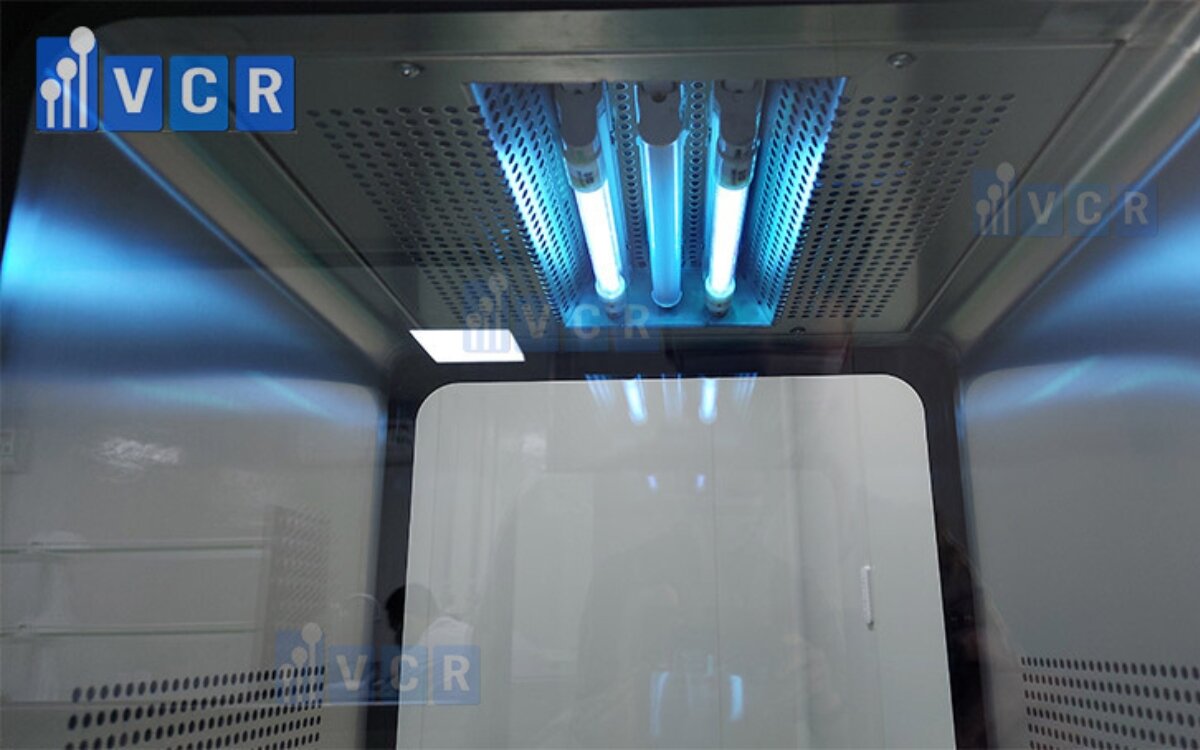

2.4 Anti-Static (ESD-Safe) Lights

- Features: Housings coated with electrostatic discharge (ESD) material; surfaces resist charge buildup.

- Advantages: Prevents electrostatic discharge that could damage sensitive microcomponents.

- Primary Use: PCB assembly zones, electronic parts storage, high-ESD workstations.

Quick Comparison Table

|

Light Type |

Key Features |

Primary Applications |

|

LED Panel |

Recessed mount, diffused uniform lighting |

SMT lines, testing rooms |

|

LED T5/T8 |

Surface-mounted, easy replacement |

Hallways, auxiliary rooms |

|

IP65 Dustproof Light |

Moisture-resistant, fully sealed casing |

Wet areas, component washing zones |

|

Anti-Static (ESD) |

ESD-coated housing, prevents static buildup |

Sensitive component areas, technical benches |

See more: Navigating FDA and ISO Standards for Clean Room Lighting in Food Manufacturing

3. Latest 2025 Price List for Cleanroom Lighting

Choosing the right cleanroom lighting requires not only technical compliance but also budget considerations. Below is a reference price list updated for 2025, featuring the most commonly used light fixtures in electronics manufacturing plants.

Summary Price Table - Common Cleanroom Lights

|

Product Name |

Reference Price |

Power |

Warranty |

|

LED Panel 600x600mm |

680,000 VND |

36W |

24 months |

|

LED Tube T8 |

150,000 VND |

18W |

12 months |

|

IP65 Dustproof Light |

920,000 VND |

40W |

24 months |

|

ESD LED Light 1200mm |

1,150,000 VND |

20W |

18 months |

Note:

- Prices are for reference only.

- Actual quotations may vary depending on:

- Order quantity

- Type of LED chip used (e.g., Osram, Samsung, Nichia…)

- Specific technical requirements for different cleanroom zones

Contact VCR for a detailed quotation and consultation on the most suitable lighting solution for your cleanroom classification.

4. Factors Affecting Cleanroom Light Pricing

Cleanroom lighting prices are influenced not only by wattage or size but also by technical specifications related to cleanroom standards, material selection, and usage environment. Here are four key pricing factors:

4.1. Cleanroom Classification Standard (ISO 5/6/7/8)

Each ISO 14644 classification defines the maximum allowable number of airborne particles. The higher the class (ISO 5-6), the stricter the design requirements:

- Fully sealed surfaces, no dust-trapping gaps

- Non-disruptive to laminar airflow

- Lights for ISO 5-6 typically cost 20-40% more than those for ISO 7-8 due to stricter technical demands.

4.2. Housing Material & ESD Resistance

The housing material directly affects durability and compatibility with cleanroom environments:

- Stainless Steel 304/316L: Chemical-resistant, used in pharmaceutical or harsh environments → higher cost

- High-grade PC or PMMA plastic: Moldable, impact-resistant → mid-range price

- ESD coating: Prevents static buildup—mandatory for microcircuit zones → increases production cost

4.3. LED Chip & Driver Quality

The LED chip determines lighting quality, lifespan, and efficiency:

- Osram, Samsung, Nichia: High durability, excellent CRI, efficiency >120 lm/W → more expensive than unbranded chips

- Drivers: Integrated flicker-free, thermal and surge protection features can raise pricing by 15-25%

4.4. Order Quantity & Project Discounts

For large-scale orders (e.g., full factory lighting), tiered pricing is typically applied:

- Retail purchase: Listed price

- Projects ≥ 50 lights: 5-10% discount

- Projects ≥ 200 lights: Custom chip brand & design negotiable

See more:Demystifying the Difference Cleanroom LED Panel Lights vs. Ordinary Options

5. Recommended Lighting Selection by Production Area

In electronics manufacturing plants, each area has its own specific requirements—from lighting intensity and cleanliness level to electrostatic resistance. Choosing the right lighting for each zone not only optimizes investment but also ensures efficient operation and compliance with technical standards.

Suggested Cleanroom Light Selection by Area

|

Production Area |

Recommended Light Type |

Technical Notes |

|

SMT Room |

ESD LED Panel 600x600 |

High brightness, anti-static, flush ceiling-mounted |

|

Testing Room |

Neutral White LED Panel |

Non-glare, 4000K color temperature enhances color differentiation |

|

Hallways |

T8 LED Tube |

Energy-saving, easy to replace, sufficient basic illumination |

|

Air Shower |

IP65 Dust & Water-Resistant Light |

Sealed housing, moisture-proof, washable, highly durable |

Key Considerations by Area

- SMT & Microcomponent Areas: High ESD control requirements → Use lights with anti-static coating.

- Testing & QC Areas: Require neutral, flicker-free lighting → Helps technicians focus and avoid eye strain.

- Hallways & Utility Zones: T8 lights are cost-effective while still meeting basic safety lux levels.

- Air Showers & Frequently Cleaned Zones: Require IP65 or higher-rated lights for dust and water resistance.

6. VCR's Customer Support & Consultation Policy

With over 10 years of experience supplying cleanroom equipment to the electronics industry, VCR not only offers high-quality products but also emphasizes after-sales service and comprehensive technical consulting. Here are the exclusive support policies for cleanroom lighting customers:

1. Free Lighting Layout Consultation Based on ISO 14644

VCR provides on-site surveys and customized lighting layout design based on your cleanroom classification (ISO 5-8), ensuring:

- Even light distribution

- No shadowing on work areas

- Compliance with laminar airflow standards

This service is especially useful for SMT rooms, testing rooms, and microcomponent weighing areas.

2. Full Technical Documentation Provided

Each lighting product can be delivered with the following documents:

- CO (Certificate of Origin)

- CQ (Certificate of Quality)

- Lux test reports, optical parameters, EMC and RoHS test reports (upon request)

These documents help clients quickly prepare for GMP/ISO audits and acceptance procedures.

3. Nationwide Delivery & Local Support

- Nationwide shipping and door-to-door delivery for both small and large-scale projects

- 24-hour on-site warranty service available in:

- Hanoi, Bac Ninh, Hai Phong, Bac Giang

- Ho Chi Minh City, Binh Duong, Dong Nai

- Technical support hotline available on all working days—ready for both remote and on-site assistance

VCR Commitment

Products meet cleanroom standards

Solutions tailored to your actual needs—no mis-selling

Prompt, transparent, and professional support

See more: 9 Aspects of LED Light Specification You Need to Understand

7. Frequently Asked Questions About Cleanroom Lights

1. Do cleanroom LED panel lights need to be ESD-compliant?

Yes. If the lights are installed in sensitive component areas like SMT lines or IC inspection rooms, they must have an anti-static (ESD coating) housing to prevent electrostatic discharge that could damage microelectronic components.

2. Can fluorescent tube lights be replaced with LED in cleanrooms?

Yes. Replacing fluorescent lights with T8 LED tubes designed for cleanroom use is highly recommended to:

- Save energy

- Reduce heat generation

- Extend lifespan and lower maintenance costs

3. Does VCR offer custom-sized LED panels?

Yes. VCR provides custom fabrication services for LED panel lights to match special requirements—ideal for test rooms, areas with restricted ceiling space, or non-standard lighting needs.

4. Are installation costs included in the listed cleanroom light prices?

No. Prices listed on the website or quotations do not include installation. However, VCR does offer installation support upon request in various provinces, especially in Hanoi, Bac Ninh, Ho Chi Minh City, Binh Duong, etc.

8. Contact Us Now - Get Tailored Advice & Accurate Quotations for Your Factory

Whether you need lighting for SMT rooms, testing labs, or air showers, VCR’s technical team is ready to assist you from consultation to installation.

Free lighting layout consultation according to ISO 14644

Support in selecting the right lights for each production zone

Transparent and detailed quotations tailored to your project budget

Contact us today:

Hotline: 090.123.9008

Email: [email protected]

Website: https://denphongsach.com/

Diep VCR