In the highly regulated and safety-conscious realm of food manufacturing, maintaining impeccable hygiene and contamination control is paramount.

- I. Introduction

- II. Understanding FDA and ISO Standards

- III. Specific Standards Applicable to cleanroom Lighting

- IV. Compliance Strategies

- V. Implementation Strategies for Compliance

- A. Needs Assessment and Process Mapping

- VI. Maintenance and Validation of cleanroom Lighting

- VII. Challenges and Considerations

- VIII. Best Practices for Compliance and Optimization

- IX. Conclusion

I. Introduction

In the highly regulated and safety-conscious realm of food manufacturing, maintaining impeccable hygiene and contamination control is paramount. Central to achieving these standards are cleanrooms, specialized environments meticulously designed to minimize the presence of airborne particles, microorganisms, and other contaminants. cleanrooms play a critical role in ensuring food safety and quality by controlling environmental factors such as temperature, humidity, and air purity. These controlled settings are indispensable in various stages of food production, from the handling of raw ingredients to the packaging of finished products, thereby supporting consistent product quality and safeguarding consumer health.

The importance of cleanrooms in food manufacturing cannot be overstated. Contamination can occur at any point in the production process, potentially leading to foodborne illnesses, product recalls, and significant financial losses. cleanrooms mitigate these risks by providing a sterile environment where stringent hygiene standards are maintained. This is achieved through advanced filtration systems, such as High-Efficiency Particulate Air (HEPA) filters, which remove up to 99.97% of airborne particles as small as 0.3 microns. Additionally, cleanrooms incorporate controlled access, regular sanitation protocols, and specialized equipment to prevent the introduction and spread of contaminants. By ensuring that only clean air circulates within these environments, cleanrooms support the production of safe, high-quality food products that meet both regulatory standards and consumer expectations.

Navigating the regulatory landscape is a fundamental aspect of operating cleanrooms in food manufacturing. Two pivotal frameworks govern these environments: the Food and Drug Administration (FDA) and the International Organization for Standardization (ISO). The FDA plays a central role in regulating food safety in the United States, establishing guidelines and standards that manufacturers must adhere to in order to ensure the safety and integrity of their products. Key FDA regulations affecting cleanrooms include the Food Safety Modernization Act (FSMA), which emphasizes preventive controls and risk-based approaches to food safety, and the Current Good Manufacturing Practices (CGMP), which set forth requirements for maintaining sanitary conditions and preventing contamination.

On the international front, the ISO develops and publishes a wide range of standards that provide a global benchmark for quality and safety in various industries, including food manufacturing. Notably, ISO 22000 outlines the requirements for a comprehensive food safety management system, integrating principles of Hazard Analysis and Critical Control Points (HACCP). Additionally, the ISO 14644 series specifies standards for cleanrooms and associated controlled environments, detailing classifications, testing methods, and performance criteria essential for maintaining cleanliness and preventing contamination.

The relevance of FDA and ISO standards lies in their ability to ensure legal compliance, enhance product safety, and facilitate market access. Adhering to these standards not only helps manufacturers avoid regulatory penalties and legal repercussions but also builds consumer trust by demonstrating a commitment to high-quality and safe food products. Moreover, compliance with international ISO standards enables food manufacturers to compete in global markets, as these standards are widely recognized and respected across different countries and regions.

This essay aims to explore how FDA and ISO standards apply to cleanroom lighting in food manufacturing, providing comprehensive guidance on achieving compliance and implementing best practices. By delving into specific regulations, highlighting compliance strategies, addressing common challenges, and presenting real-world case studies, the discussion seeks to equip food manufacturers with the knowledge and tools necessary to navigate the complex regulatory landscape effectively. The subsequent sections will offer detailed analyses of relevant FDA and ISO standards, outline practical compliance strategies, examine potential challenges, and illustrate successful implementations through case studies, thereby ensuring a thorough understanding of how to maintain and enhance cleanroom lighting within the framework of stringent food safety regulations.

Through this exploration, the essay underscores the critical intersection of regulatory compliance and technological implementation, emphasizing that effective cleanroom lighting is not merely a matter of operational efficiency but also a cornerstone of food safety and quality assurance in the competitive food manufacturing industry.

Read more: 5 Key Facts About Cleanroom Light

II. Understanding FDA and ISO Standards

Navigating the intricate landscape of food manufacturing regulations requires a comprehensive understanding of the standards set forth by authoritative bodies such as the Food and Drug Administration (FDA) and the International Organization for Standardization (ISO). These organizations establish guidelines that ensure food safety, quality, and operational efficiency within cleanroom environments. This section delves into the roles of the FDA and ISO in food manufacturing, explores key standards pertinent to cleanroom lighting, and provides a comparative analysis to highlight the benefits of complying with both regulatory frameworks.

A. The Role of FDA in Food Manufacturing

FDA’s Mission and Responsibilities

The Food and Drug Administration (FDA) is a pivotal regulatory body in the United States, responsible for safeguarding public health by ensuring the safety, efficacy, and security of human and veterinary drugs, biological products, medical devices, and the nation’s food supply. In the context of food manufacturing, the FDA's mission encompasses several critical responsibilities:

- Setting Safety Standards: The FDA establishes comprehensive safety standards that food manufacturers must adhere to, ensuring that food products are free from harmful contaminants and meet defined quality parameters.

- Regulatory Oversight: Through regulations and guidelines, the FDA oversees various aspects of food production, including processing, packaging, labeling, and distribution, to maintain consistency and safety across the food supply chain.

- Conducting Inspections and Enforcement: The FDA conducts regular inspections of food manufacturing facilities to verify compliance with established standards. In cases of non-compliance, the FDA has the authority to enforce corrective actions, issue fines, and mandate recalls to protect consumer health.

- Promoting Public Health: Beyond regulation, the FDA engages in educational initiatives and collaborates with industry stakeholders to promote best practices in food safety and quality management.

Key FDA Regulations Affecting cleanrooms

Several FDA regulations directly impact the design and operation of cleanrooms within food manufacturing facilities. Understanding these regulations is essential for ensuring compliance and maintaining high standards of food safety:

FSMA (Food Safety Modernization Act): Enacted in 2011, FSMA represents a paradigm shift in U.S. food safety regulation, emphasizing prevention over reaction. Key provisions of FSMA relevant to cleanrooms include:

- Preventive Controls: Facilities must implement preventive controls to identify and mitigate potential hazards that could contaminate food products. cleanroom lighting plays a role in maintaining a sterile environment, thereby supporting these preventive measures.

- Supply Chain Assurance: FSMA requires verification that suppliers adhere to safety standards, indirectly influencing the environmental controls within cleanrooms to prevent cross-contamination from incoming materials.

- Enhanced Inspection and Compliance: FSMA mandates increased FDA inspections and empowers the agency to enforce compliance more stringently, necessitating robust cleanroom protocols, including effective lighting systems.

HACCP (Hazard Analysis and Critical Control Points): HACCP is a systematic approach to identifying, evaluating, and controlling food safety hazards. While HACCP itself is a voluntary program, the FDA enforces its principles through regulations such as the FSMA. cleanroom lighting is integrated into HACCP plans as a Critical Control Point (CCP), where environmental factors like lighting contribute to hazard prevention and control.

CGMP (Current Good Manufacturing Practices): CGMP regulations outline the minimum sanitary and processing standards that food manufacturers must follow. Relevant CGMP aspects for cleanrooms include:

Sanitation Control: cleanroom lighting must facilitate thorough cleaning and sanitization, ensuring that all surfaces are free from contaminants.

Facility Design and Construction: cleanrooms must be designed with materials and fixtures that withstand regular cleaning and are compatible with UV-C lighting systems, preventing degradation and contamination.

Operational Controls: Proper maintenance and monitoring of lighting systems are required to ensure consistent performance and adherence to safety standards.

B. The Role of ISO in Food Manufacturing

Introduction to ISO

The International Organization for Standardization (ISO) is a globally recognized entity that develops and publishes international standards across various industries to ensure quality, safety, and efficiency. ISO standards are voluntary but widely adopted by organizations worldwide to demonstrate compliance with best practices and to facilitate international trade. In the realm of food manufacturing, ISO standards provide a structured framework for implementing effective management systems that uphold food safety and quality.

Key ISO Standards for Food Manufacturing

Several ISO standards are particularly relevant to cleanroom lighting in food manufacturing, each addressing different aspects of food safety and cleanroom management:

ISO 22000: Food Safety Management Systems: This standard specifies the requirements for a food safety management system (FSMS) that involves interactive communication, system management, prerequisite programs, and HACCP principles. Key aspects include:

- Systematic Approach: ISO 22000 promotes a systematic approach to food safety, integrating cleanroom lighting as part of the overall FSMS to control environmental hazards.

- Continuous Improvement: The standard emphasizes continuous improvement through regular monitoring, auditing, and updating of food safety protocols, including lighting systems, to adapt to evolving risks and technologies.

ISO 14644: cleanrooms and Associated Controlled Environments: This series of standards provides comprehensive guidelines for the design, classification, testing, and operation of cleanrooms. Key parts include:

- ISO 14644-1: Specifies classification of air cleanliness by particle concentration, which directly impacts the requirements for cleanroom lighting to maintain appropriate environmental conditions.

- ISO 14644-2: Outlines the monitoring and maintenance of cleanrooms to ensure sustained compliance with cleanliness standards, including the role of lighting in environmental control.

- ISO 14644-3: Details the testing methods for cleanrooms, ensuring that lighting systems meet the necessary performance criteria during validation and verification processes.

ISO 9001: Quality Management Systems: While not exclusively focused on food safety, ISO 9001 provides a framework for quality management that complements ISO 22000 by ensuring that all aspects of production, including cleanroom lighting, contribute to overall product quality.

ISO 50001: Energy Management Systems: This standard helps organizations establish systems to improve energy efficiency. In the context of cleanroom lighting, ISO 50001 guides the implementation of energy-efficient lighting solutions that reduce operational costs and environmental impact without compromising sanitation efficacy.

C. Comparative Analysis of FDA and ISO Standards

Overlap and Differences

While both FDA and ISO standards aim to ensure food safety and quality, they approach regulation from different angles and with varying scopes:

- Regulatory vs. Voluntary Frameworks: The FDA operates as a governmental regulatory body with mandatory compliance requirements, especially within the United States. In contrast, ISO standards are voluntary and internationally recognized, allowing organizations to adopt them based on their operational needs and market demands.

- Scope of Standards: FDA regulations, such as FSMA and CGMP, provide specific legal requirements that food manufacturers must follow to operate within the U.S. market. ISO standards, like ISO 22000 and ISO 14644, offer broader guidelines that facilitate global standardization and best practices in food safety and cleanroom management.

- Integration of Standards: FDA regulations often incorporate HACCP principles, which align closely with ISO 22000’s emphasis on risk-based food safety management systems. Both frameworks advocate for proactive hazard identification and control measures, including the role of cleanroom lighting in contamination prevention.

- Enforcement Mechanisms: The FDA enforces compliance through inspections, audits, and penalties for non-compliance, ensuring that food manufacturers adhere to mandatory standards. ISO standards rely on voluntary adoption and certification through third-party audits, encouraging organizations to pursue compliance for competitive advantage and market access rather than legal necessity.

Benefits of Compliance with Both

Adhering to both FDA and ISO standards offers comprehensive benefits that enhance overall food safety and operational excellence:

- Enhanced Food Safety: Compliance with FDA regulations ensures that food manufacturers meet strict legal requirements for food safety within the United States. Simultaneously, ISO standards provide a structured framework for managing food safety risks on a global scale, ensuring that products meet international safety and quality expectations.

- Operational Efficiency: Implementing ISO standards like ISO 9001 and ISO 50001 alongside FDA regulations promotes a culture of continuous improvement and efficiency. Streamlined processes, energy-efficient lighting solutions, and robust quality management systems contribute to lower operational costs and higher productivity.

- Market Access and Credibility: Certification to ISO standards facilitates access to international markets by demonstrating compliance with globally recognized quality and safety benchmarks. Combined with FDA compliance, this dual adherence enhances the credibility and reputation of food manufacturers, fostering consumer trust and expanding business opportunities.

- Risk Management: Both FDA and ISO standards emphasize risk-based approaches to food safety, encouraging proactive identification and mitigation of potential hazards. This comprehensive risk management strategy reduces the likelihood of contamination incidents, product recalls, and legal repercussions, safeguarding both public health and the manufacturer’s bottom line.

- Competitive Advantage: Organizations that comply with both FDA and ISO standards position themselves as leaders in food safety and quality management. This dual compliance differentiates them from competitors, attracting quality-conscious consumers and partners who prioritize safety and reliability in food products.

III. Specific Standards Applicable to cleanroom Lighting

Ensuring compliance with regulatory standards is essential for maintaining the integrity and safety of food production cleanrooms. Both the Food and Drug Administration (FDA) and the International Organization for Standardization (ISO) provide comprehensive guidelines that govern various aspects of cleanroom operations, including lighting. This section delves into the specific FDA and ISO standards applicable to cleanroom lighting in food manufacturing, outlining key regulations, requirements, and best practices to achieve and sustain compliance.

A. FDA Standards for cleanroom Lighting

The FDA plays a crucial role in regulating food manufacturing processes to ensure public health and safety. Several FDA regulations specifically impact cleanroom lighting, focusing on maintaining sanitary conditions, preventing contamination, and ensuring consistent product quality.

1. Current Good Manufacturing Practices (CGMP) Requirements

CGMP are a set of regulations enforced by the FDA that provide guidelines for manufacturing, processing, packaging, or holding food products. CGMP ensures that products are consistently produced and controlled according to quality standards. In the context of cleanroom lighting, CGMP requirements encompass several key aspects:

- Lighting Intensity: CGMP mandates adequate lighting levels to ensure proper visibility for operators performing critical tasks. Insufficient lighting can lead to errors in handling materials, improper sanitation, and increased risk of contamination. The required lighting intensity is typically measured in lux, with specific recommendations depending on the cleanroom classification and the nature of the tasks performed.

- Uniformity of Lighting: To prevent shadowed areas where contaminants might accumulate, CGMP emphasizes the importance of uniform lighting distribution. Uniform illumination ensures that all surfaces are visible and accessible for cleaning and inspection, thereby minimizing blind spots that could harbor pathogens.

- Maintenance and Sanitation: CGMP requires regular maintenance and cleaning of lighting fixtures to prevent the buildup of dust, debris, and microorganisms. This includes routine inspections, cleaning schedules, and prompt replacement of faulty or degraded lamps. Proper maintenance ensures that lighting systems remain effective and do not become sources of contamination.

- Durable Materials: Lighting fixtures and components must be constructed from materials that resist corrosion, wear, and chemical exposure. Durable materials ensure that lighting systems maintain their integrity and functionality over time, even in harsh cleanroom environments.

Adhering to CGMP standards for cleanroom lighting not only ensures compliance but also enhances overall sanitation and operational efficiency within food manufacturing facilities.

2. Food Safety Modernization Act (FSMA) and cleanroom Lighting

FSMA enacted in 2011, represents a significant overhaul of U.S. food safety regulations, shifting the focus from reactive measures to proactive prevention. FSMA impacts cleanroom lighting through several provisions that emphasize preventive controls and environmental monitoring:

- Preventive Controls: FSMA requires food facilities to implement preventive controls to identify and mitigate potential hazards that could contaminate food products. cleanroom lighting plays a critical role in these preventive measures by maintaining a sterile environment, reducing microbial loads, and preventing contamination during food processing.

- Environmental Monitoring: FSMA mandates rigorous environmental monitoring programs to continuously assess the cleanliness and safety of food production environments. cleanroom lighting systems must be integrated into these monitoring programs to ensure consistent disinfection and to provide reliable data on environmental conditions. Automated lighting controls and monitoring sensors can facilitate real-time tracking of lighting performance, ensuring that preventive controls remain effective.

- Supplier Verification: FSMA also emphasizes the importance of verifying that suppliers adhere to food safety standards. Proper cleanroom lighting ensures that incoming materials are handled in a controlled environment, reducing the risk of contamination from external sources.

By aligning cleanroom lighting systems with FSMA requirements, food manufacturers can proactively manage contamination risks, enhance food safety, and ensure compliance with modern regulatory standards.

3. Hazard Analysis and Critical Control Points (HACCP) and Lighting Considerations

HACCP is a systematic preventive approach to food safety that identifies, evaluates, and controls hazards that are significant for food safety. Integrating lighting into HACCP plans involves identifying lighting-related factors as Critical Control Points (CCPs) and establishing protocols to manage them effectively:

- Identification of CCPs: In cleanrooms, lighting can be identified as a CCP where insufficient lighting or shadowed areas pose significant contamination risks. Effective lighting ensures that critical tasks are performed under optimal visibility conditions, reducing the likelihood of errors that could lead to contamination.

- Critical Limits: For each lighting-related CCP, specific critical limits must be established. These limits include minimum lighting intensity levels (lux), uniformity standards, and maintenance intervals. Exceeding or falling short of these limits can compromise food safety, necessitating immediate corrective actions.

- Monitoring Procedures: Continuous monitoring of lighting systems is essential to ensure that critical limits are consistently met. This includes regular measurements of lighting intensity, inspections for uniformity, and verification of maintenance activities. Automated monitoring systems can enhance the reliability and accuracy of these procedures.

- Corrective Actions: In the event of a deviation from critical limits, predefined corrective actions must be implemented promptly. These actions may include adjusting lighting intensity, cleaning or replacing fixtures, and reassessing cleanroom protocols to prevent recurrence.

Integrating cleanroom lighting into HACCP plans ensures that environmental factors contributing to contamination risks are effectively managed, thereby enhancing overall food safety and compliance with HACCP principles.

B. ISO Standards for cleanroom Lighting

The International Organization for Standardization (ISO) develops and publishes international standards that promote quality, safety, and efficiency across various industries, including food manufacturing. ISO standards provide a globally recognized framework for implementing best practices in cleanroom management, including lighting.

1. ISO 14644 Series

The ISO 14644 series is a comprehensive set of standards specifically addressing cleanrooms and associated controlled environments. It consists of multiple parts, each focusing on different aspects of cleanroom management:

- ISO 14644-1: Classification of Air Cleanliness: This standard defines the classification of air cleanliness based on the concentration of airborne particles. cleanrooms are categorized into different classes (e.g., ISO Class 5, Class 6) depending on the allowable number of particles per cubic meter. cleanroom lighting must be designed to maintain these classifications by preventing particulate accumulation and ensuring adequate visibility for monitoring air quality.

- ISO 14644-2: Monitoring to Maintain Cleanliness: This part outlines the requirements for ongoing monitoring and maintenance of cleanrooms to sustain the defined air cleanliness levels. Lighting systems are integral to this process, as they facilitate visual inspections, maintenance tasks, and environmental monitoring activities. Proper lighting ensures that all areas are accessible and that monitoring devices can function effectively.

- ISO 14644-3: Test Methods: ISO 14644-3 specifies the testing methods for cleanrooms and their associated systems, including lighting. This includes procedures for verifying the uniformity of lighting, assessing the efficacy of UV-C disinfection systems, and validating the overall performance of lighting fixtures. Adhering to these test methods ensures that cleanroom lighting systems meet the required standards and perform reliably under operational conditions.

The ISO 14644 series provides detailed guidelines that help food manufacturers design, operate, and maintain cleanroom lighting systems that meet international cleanliness and safety standards.

2. ISO 22000 Requirements

ISO 22000 is an internationally recognized standard that outlines the requirements for a food safety management system (FSMS). It integrates principles of HACCP and emphasizes a risk-based approach to food safety. ISO 22000 encompasses cleanroom lighting within its broader framework, ensuring that environmental controls contribute to the overall food safety objectives:

- Risk-Based Approach: ISO 22000 requires organizations to identify and assess risks related to food safety, including those associated with cleanroom lighting. This involves evaluating how lighting systems impact contamination control and implementing measures to mitigate identified risks.

- Integration with FSMS: cleanroom lighting is integrated into the FSMS to support the identification, evaluation, and control of hazards. This includes establishing lighting-related procedures, monitoring protocols, and maintenance schedules that align with the overall FSMS objectives.

- Continuous Improvement: ISO 22000 promotes continuous improvement through regular audits, performance evaluations, and updates to management systems. This ensures that cleanroom lighting systems evolve in response to changing risks, technological advancements, and regulatory requirements.

By incorporating cleanroom lighting into ISO 22000, food manufacturers can enhance their FSMS, ensuring that environmental controls effectively support food safety and quality.

3. Additional Relevant ISO Standards

Beyond ISO 22000 and the ISO 14644 series, several other ISO standards impact cleanroom lighting in food manufacturing:

- ISO 9001: Quality Management Systems: ISO 9001 provides a framework for establishing a quality management system (QMS) that ensures consistent product quality and customer satisfaction. In the context of cleanroom lighting, ISO 9001 emphasizes the importance of documented procedures, regular inspections, and continuous improvement practices that ensure lighting systems contribute to overall quality objectives.

- ISO 50001: Energy Management Systems: ISO 50001 focuses on energy efficiency and the systematic management of energy use within organizations. Applying ISO 50001 to cleanroom lighting involves implementing energy-efficient lighting solutions, such as LED technology, and optimizing lighting operations to reduce energy consumption without compromising disinfection efficacy. This standard supports sustainable manufacturing practices and helps food manufacturers achieve cost savings through reduced energy usage.

These additional ISO standards complement the primary cleanroom and food safety standards, providing a holistic approach to managing quality, energy efficiency, and overall operational excellence in food manufacturing environments.

C. Lighting Specifications and Requirements

Adhering to specific lighting specifications and requirements is essential for ensuring that cleanroom lighting systems effectively support food safety and quality objectives. These specifications encompass aspects such as lighting intensity, uniformity, energy efficiency, and maintenance protocols.

1. Intensity and Uniformity

- Lighting Levels (Lux): cleanroom lighting must provide sufficient illumination to ensure that all critical tasks are performed with adequate visibility. The required lighting intensity, measured in lux, varies depending on the cleanroom classification and the nature of the operations. For example, ISO Class 5 cleanrooms typically require higher lighting levels (e.g., 300-500 lux) to facilitate detailed inspections and precise handling of materials, whereas lower classifications may necessitate reduced lighting levels.

- Uniform Distribution: Uniform lighting distribution is crucial to prevent shadowed areas where contaminants might accumulate. Lighting systems should be designed to ensure consistent illumination across all surfaces and workstations. This involves using multiple light sources, strategic placement of fixtures, and the incorporation of reflective surfaces to enhance light dispersion and eliminate dark spots.

- Task-Specific Lighting: In addition to general lighting, task-specific lighting may be required in certain areas of the cleanroom. Adjustable fixtures, such as pendant lights or adjustable arm lamps, provide focused illumination for intricate tasks, ensuring precision and minimizing the risk of contamination due to inadequate visibility.

2. Energy Efficiency and Sustainability

- Compliance with Energy Standards: cleanroom lighting systems must comply with energy consumption standards to promote sustainability and reduce operational costs. This involves selecting energy-efficient lighting technologies, such as LED lamps, which offer superior energy performance compared to traditional incandescent or fluorescent lamps. LEDs not only consume less power but also have longer lifespans, reducing the frequency of replacements and maintenance activities.

- Sustainable Lighting Solutions: Implementing sustainable lighting solutions supports environmental stewardship and aligns with corporate sustainability goals. Features such as motion sensors, automated dimming controls, and daylight harvesting systems optimize energy usage by adjusting lighting levels based on occupancy and natural light availability. These technologies ensure that energy is used efficiently without compromising the cleanliness and safety of the environment.

- Eco-Friendly Materials: Selecting lighting fixtures made from recyclable and non-toxic materials further enhances the sustainability of cleanroom lighting systems. Eco-friendly materials reduce the environmental impact of lighting infrastructure and support the circular economy by facilitating recycling and reuse of components.

3. Maintenance and Validation

- Regular Maintenance: Ensuring the ongoing effectiveness of cleanroom lighting systems requires regular maintenance and inspection. This includes routine cleaning of lamps and fixtures to prevent the buildup of dust and contaminants that can block UV-C radiation and reduce disinfection efficacy. Maintenance schedules should be established based on manufacturer recommendations and operational demands, ensuring that lighting systems remain in optimal condition.

- Component Replacement: Timely replacement of lighting components, such as lamps, ballasts, and reflective surfaces, is essential to maintain consistent performance. Degraded or faulty components can compromise lighting intensity and uniformity, undermining contamination control efforts. Establishing a proactive replacement strategy minimizes downtime and ensures continuous compliance with lighting standards.

- Validation Procedures: cleanroom lighting systems must undergo regular validation to confirm that they meet specified performance criteria. Validation involves measuring lighting intensity, uniformity, and energy consumption, as well as assessing the effectiveness of UV-C disinfection in inactivating pathogens. Documentation of validation results is critical for regulatory compliance and audit readiness, providing evidence that lighting systems operate within defined parameters and contribute to food safety objectives.

- Automated Monitoring and Controls: Integrating automated monitoring systems with cleanroom lighting facilitates real-time tracking of performance metrics and simplifies maintenance tasks. Sensors that measure light intensity, exposure duration, and environmental conditions provide actionable data that can be used to optimize lighting operations and identify potential issues before they escalate. Automated controls enable dynamic adjustments to lighting settings based on real-time data, ensuring consistent disinfection efficacy and energy efficiency.

By adhering to these lighting specifications and requirements, food manufacturers can ensure that their cleanroom lighting systems effectively support contamination control, enhance food safety, and maintain compliance with FDA and ISO standards.

IV. Compliance Strategies

Ensuring adherence to FDA and ISO standards for cleanroom lighting in food manufacturing requires a strategic and systematic approach. Compliance strategies encompass conducting thorough audits, designing compliant lighting systems, maintaining meticulous documentation, educating and training staff, and leveraging advanced technologies. Implementing these strategies not only ensures regulatory compliance but also enhances overall operational efficiency and food safety standards. This section outlines the essential compliance strategies that food manufacturers should adopt to navigate FDA and ISO standards effectively.

A. Conducting a Compliance Audit

Initial Assessment

The first step in achieving compliance with FDA and ISO standards is conducting a comprehensive compliance audit of existing cleanroom lighting systems. This initial assessment involves evaluating the current lighting infrastructure against the specific requirements outlined in relevant FDA regulations (such as CGMP, FSMA, and HACCP) and ISO standards (including ISO 22000 and ISO 14644 series). Key activities during the initial assessment include:

- Reviewing Lighting Specifications: Assessing whether the current lighting intensity, uniformity, and energy efficiency meet the prescribed standards.

- Inspecting Equipment and Fixtures: Examining the condition and functionality of existing lighting fixtures, ensuring they are free from defects and capable of maintaining required performance levels.

- Evaluating Maintenance Practices: Analyzing the effectiveness of current maintenance schedules and procedures to identify any lapses that could lead to non-compliance.

- Assessing Integration with cleanroom Systems: Ensuring that lighting systems are properly integrated with HVAC and other environmental control systems to support overall cleanroom integrity.

Identifying Gaps

Once the initial assessment is complete, the next step is to identify gaps where current lighting systems fall short of compliance standards. Techniques for identifying non-compliance areas include:

- Comparative Analysis: Comparing current lighting practices and specifications with FDA and ISO requirements to pinpoint discrepancies.

- Inspection Checklists: Utilizing detailed checklists based on regulatory standards to systematically identify areas of non-compliance.

- Interviews and Feedback: Engaging with operational staff and maintenance personnel to gather insights on potential issues and inefficiencies related to lighting systems.

- Performance Testing: Conducting empirical tests to measure lighting intensity, uniformity, and energy consumption, ensuring they align with regulatory benchmarks.

Prioritizing corrective actions based on the severity and impact of identified gaps is crucial. High-priority issues that directly affect food safety and regulatory compliance should be addressed promptly to mitigate risks and ensure continuous adherence to standards.

Read more: 9 Aspects of LED Light Specification

B. Designing Compliance-Ready Lighting Systems

Selecting Appropriate Lighting Technology

Choosing the right lighting technology is fundamental to meeting FDA and ISO standards. Food manufacturers must consider several factors when selecting lighting solutions:

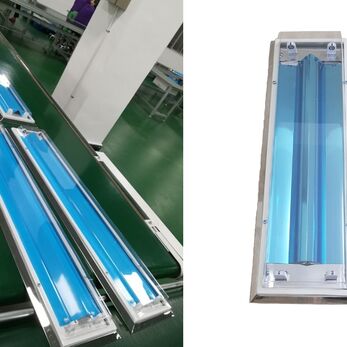

UV-C and LED Technologies: UV-C lamps are essential for microbial disinfection, while LED lights offer energy efficiency and longevity. Selecting a combination of these technologies can enhance both sanitation and operational efficiency.

- Regulatory Compliance: Ensuring that selected lighting technologies comply with specific regulatory requirements, such as UV-C intensity levels and energy consumption limits.

- Performance and Reliability: Opting for high-quality lighting fixtures that provide consistent performance and have a proven track record in cleanroom environments.

- Sustainability: Prioritizing energy-efficient and eco-friendly lighting options to align with ISO 50001 standards for energy management and sustainability goals.

Integration with cleanroom Design

Seamless integration of lighting systems into the architectural and operational design of cleanrooms is essential for maintaining compliance and optimizing functionality. Key considerations include:

- Architectural Layout: Designing lighting placements that ensure uniform coverage and eliminate shadowed areas, thereby enhancing visibility and disinfection efficacy.

- Modular and Scalable Systems: Implementing modular lighting solutions that can be easily adjusted or expanded as cleanroom requirements evolve, supporting flexibility in operations.

- Coordination with Environmental Controls: Ensuring that lighting systems work in harmony with HVAC and other environmental control systems to maintain optimal cleanroom conditions.

- Aesthetic and Functional Balance: Balancing the need for effective lighting with the aesthetic and spatial design of cleanrooms, ensuring that lighting fixtures do not impede workflow or create operational bottlenecks.

C. Documentation and Record-Keeping

Essential Documentation

Maintaining detailed and accurate documentation is a cornerstone of regulatory compliance. Essential documentation related to cleanroom lighting includes:

- Lighting Specifications: Detailed records of lighting types, intensities, distribution patterns, and energy consumption metrics.

- Maintenance Logs: Comprehensive logs documenting all maintenance activities, including cleaning, bulb replacements, inspections, and repairs.

- Compliance Audits: Records of all compliance audits, including findings, corrective actions taken, and verification of compliance with FDA and ISO standards.

- Validation Reports: Documentation of validation procedures and results, demonstrating that lighting systems meet required performance criteria and disinfection efficacy.

Traceability and Accountability

Ensuring traceability and accountability involves establishing clear records that link lighting-related actions to responsible personnel and specific compliance outcomes. This approach includes:

- Action Logs: Keeping detailed logs of all actions taken to address compliance gaps, including timelines and responsible individuals.

- Audit Trails: Maintaining a transparent audit trail that allows for easy tracking of compliance-related activities and decisions, facilitating accountability during regulatory inspections.

- Standardized Forms and Templates: Utilizing standardized documentation forms and templates to ensure consistency and completeness in record-keeping practices.

- Digital Record-Keeping Systems: Implementing digital systems for storing and managing documentation, enhancing accessibility, searchability, and security of compliance records.

D. Training and Staff Education

Comprehensive Training Programs

Educating staff on the importance of compliance and the proper operation and maintenance of lighting systems is essential for sustaining regulatory adherence. Comprehensive training programs should include:

- Regulatory Awareness: Training employees on the specific FDA and ISO standards relevant to cleanroom lighting, ensuring they understand the requirements and their roles in achieving compliance.

- Operational Procedures: Educating staff on the correct operation of lighting systems, including adjusting settings, performing routine maintenance, and responding to system alerts or malfunctions.

- Sanitation Protocols: Instructing employees on best practices for cleaning and sanitizing lighting fixtures to prevent contamination and maintain system integrity.

- Safety Training: Providing training on safety measures related to UV-C lighting, including the use of personal protective equipment (PPE) and adherence to safety protocols to prevent accidental exposure.

Continuous Education

Implementing ongoing training initiatives ensures that staff remain updated on changes in standards and best practices. Continuous education strategies include:

- Regular Workshops and Seminars: Hosting periodic training sessions to reinforce compliance principles and introduce new regulatory updates or technological advancements.

- E-Learning Modules: Offering online training modules that allow employees to learn at their own pace and revisit important topics as needed.

- Certification Programs: Encouraging staff to obtain relevant certifications in food safety management and cleanroom operations, enhancing their expertise and commitment to compliance.

- Feedback Mechanisms: Establishing feedback systems where employees can share insights, ask questions, and suggest improvements to lighting and compliance practices.

E. Leveraging Technology for Compliance

Automation and Monitoring Systems

Utilizing automated lighting controls and real-time monitoring systems is critical for maintaining consistent compliance with FDA and ISO standards. Key strategies include:

- Automated Controls: Implementing automated lighting control systems that adjust lighting intensity and distribution based on real-time environmental conditions and operational needs. Automation reduces the risk of human error and ensures that lighting systems operate within specified parameters.

- Real-Time Monitoring: Deploying sensors and monitoring devices that track lighting performance metrics, such as intensity, uniformity, and energy consumption, in real time. These systems provide immediate alerts in case of deviations, enabling prompt corrective actions.

- Integration with Management Systems: Linking lighting controls with broader cleanroom management systems, such as Supervisory Control and Data Acquisition (SCADA), facilitates centralized monitoring and control, enhancing overall operational efficiency and compliance.

Data Analytics and Reporting

Implementing data-driven approaches to track lighting performance and generate compliance reports is essential for proactive management and continuous improvement. Effective data analytics and reporting strategies include:

- Performance Dashboards: Creating dashboards that display key lighting performance indicators (KPIs) in real time, allowing managers to monitor compliance and identify trends or issues quickly.

- Predictive Maintenance: Using data analytics to predict potential lighting system failures or maintenance needs based on historical performance data, enabling proactive maintenance and reducing downtime.

- Compliance Reporting: Generating automated compliance reports that summarize lighting performance against FDA and ISO standards, facilitating easy access to documentation during audits and inspections.

- Continuous Improvement: Analyzing collected data to identify areas for improvement, optimize lighting operations, and enhance overall compliance and efficiency.

V. Implementation Strategies for Compliance

Achieving compliance with FDA and ISO standards for cleanroom lighting in food manufacturing necessitates a systematic and strategic approach. Implementation strategies encompass conducting thorough needs assessments, fostering collaboration with specialized vendors, ensuring seamless installation and integration, and developing comprehensive training programs and Standard Operating Procedures (SOPs). This section outlines these key strategies, providing a roadmap for food manufacturers to effectively navigate and adhere to regulatory standards.

A. Needs Assessment and Process Mapping

Identifying Specific Requirements

The foundation of effective compliance lies in a detailed needs assessment that aligns lighting systems with the specific requirements of the manufacturing processes. This involves:

- Analyzing Contamination Risks: Evaluating various stages of the food production process to identify points where contamination is most likely to occur. Understanding these risks helps determine the necessary lighting specifications, such as intensity and uniformity, to mitigate contamination.

- Operational Demands: Assessing the operational workflows to ensure that lighting systems support efficient and safe production. This includes determining the lighting needs for different tasks, such as inspection, handling of raw materials, and packaging, to ensure optimal visibility and operational efficiency.

- Regulatory Requirements: Mapping out the specific FDA and ISO standards that apply to each stage of the manufacturing process. This ensures that the lighting systems not only meet general cleanliness standards but also address specific regulatory mandates related to disinfection and environmental control.

Process Flow Analysis

Once the specific requirements are identified, a comprehensive process flow analysis is essential to integrate compliant lighting solutions seamlessly into existing workflows:

- Mapping Material Transfer Points: Identifying all points where materials are transferred within the cleanroom, such as from storage to processing areas, helps in determining where additional lighting or specialized fixtures may be necessary to prevent contamination.

- Workflow Integration: Ensuring that lighting systems do not disrupt the existing workflow involves strategically placing fixtures to complement the movement of materials and personnel. This minimizes operational interruptions and maintains the efficiency of the production process.

- Risk Mitigation: Incorporating lighting solutions that address identified contamination risks at critical points in the workflow ensures that potential hazards are effectively controlled. This proactive approach reduces the likelihood of contamination incidents and enhances overall food safety.

B. Collaboration with Designers and Manufacturers

Engaging with Specialized Vendors

Partnering with vendors who specialize in cleanroom lighting solutions is crucial for achieving compliance:

- Expertise and Experience: Selecting vendors with a proven track record in designing and supplying compliant lighting systems ensures that the solutions provided meet the stringent requirements of FDA and ISO standards. These vendors bring specialized knowledge and experience, facilitating the development of effective and reliable lighting systems.

- Customization and Flexibility: Working with specialized vendors allows for the customization of lighting solutions to fit the unique needs of the facility. This includes tailoring lighting intensity, distribution, and fixture design to align with specific contamination control and operational requirements.

- Technical Support and Consultation: Engaging vendors who offer comprehensive technical support and consultation services ensures that any challenges encountered during the design and implementation phases are promptly addressed. This collaborative approach enhances the quality and effectiveness of the lighting systems.

Iterative Design and Feedback Loops

An iterative design process, incorporating continuous feedback from stakeholders, is essential for refining lighting systems to meet compliance standards:

- Prototyping and Testing: Developing prototypes of lighting systems allows for practical testing and validation of their effectiveness in controlling contamination. This phase helps identify any design flaws or areas needing improvement before full-scale implementation.

- Stakeholder Involvement: Involving key stakeholders, including quality assurance teams, production managers, and maintenance personnel, in the design process ensures that the lighting solutions address all practical and compliance-related concerns. Their feedback provides valuable insights that enhance the functionality and compliance of the lighting systems.

- Refinement Based on Audits: Incorporating feedback from initial compliance audits into the design and implementation process helps in fine-tuning the lighting systems to fully meet regulatory standards. This iterative feedback loop ensures that the final lighting solutions are both compliant and operationally effective.

C. Installation and Integration

Site Preparation

Proper site preparation is critical for the successful installation of compliant lighting systems:

- Infrastructure Modifications: Assessing and modifying the existing infrastructure to accommodate new lighting systems is essential. This may involve installing new electrical connections, reinforcing mounting points, or modifying ceiling structures to support additional fixtures.

- Environmental Controls: Ensuring that the installation process does not disrupt existing environmental controls, such as HVAC systems, is vital for maintaining cleanroom integrity. Coordination with environmental control systems ensures that lighting installations do not negatively impact air quality or temperature regulation.

- Compliance with Installation Standards: Adhering to specific installation standards set forth by FDA and ISO ensures that lighting systems are installed correctly and operate as intended. This includes following manufacturer guidelines, regulatory specifications, and industry best practices during the installation process.

Seamless Integration with Existing Systems

Integrating new lighting systems with existing cleanroom infrastructure requires careful planning and execution:

- HVAC and Automation Coordination: Coordinating lighting installations with HVAC and automation systems ensures that all environmental controls work harmoniously. For example, integrating UV-C lighting with HVAC systems can enhance air purification and maintain optimal air quality within the cleanroom.

- Minimizing Operational Disruptions: Implementing lighting systems in a way that does not disrupt ongoing operations is crucial for maintaining productivity. This involves scheduling installations during non-operational hours or implementing phased rollouts to ensure continuous production without significant interruptions.

- System Compatibility: Ensuring that new lighting systems are compatible with existing automation and control systems facilitates seamless operation and monitoring. This compatibility enhances the overall efficiency and reliability of the cleanroom’s environmental controls.

D. Training and SOP Development

Comprehensive Staff Training

Educating staff on the new lighting systems, operational procedures, maintenance protocols, and emergency responses is essential for maintaining compliance:

- Operational Training: Providing detailed training on how to operate the new lighting systems ensures that staff can use them effectively and safely. This includes instructions on adjusting settings, monitoring performance, and troubleshooting common issues.

- Maintenance Protocols: Training maintenance personnel on the specific maintenance requirements of the new lighting systems ensures that they can perform necessary upkeep tasks, such as cleaning, bulb replacement, and system inspections, effectively and efficiently.

- Safety Procedures: Educating staff on safety measures related to lighting systems, especially UV-C lighting, is crucial for preventing accidents and ensuring a safe working environment. This includes the proper use of personal protective equipment (PPE) and adherence to safety protocols to avoid accidental exposure.

Developing Standard Operating Procedures (SOPs)

Creating detailed SOPs for the operation, maintenance, and emergency management of lighting systems ensures consistent and compliant use:

- Daily Operations: SOPs should outline the standard procedures for operating lighting systems during daily production activities, ensuring that lighting conditions remain optimal for contamination control.

- Maintenance Guidelines: Developing clear maintenance guidelines helps in performing routine upkeep tasks systematically, reducing the risk of system failures and non-compliance.

- Emergency Responses: Establishing protocols for responding to lighting system malfunctions or safety incidents ensures that any issues are addressed promptly and effectively, minimizing the impact on operations and maintaining compliance.

- Documentation and Record-Keeping: Including procedures for documenting all lighting-related activities within SOPs supports traceability and accountability, facilitating compliance audits and inspections.

VI. Maintenance and Validation of cleanroom Lighting

Maintaining and validating cleanroom lighting systems is essential for ensuring ongoing compliance with FDA and ISO standards in food manufacturing. Effective maintenance practices and rigorous validation processes not only sustain the performance and reliability of lighting systems but also uphold the stringent hygiene and safety requirements critical to food production. This section explores the key aspects of maintaining and validating cleanroom lighting, including routine maintenance practices, ongoing validation and requalification, troubleshooting common issues, and meticulous documentation.

A. Routine Maintenance Practices

Scheduled Inspections and Cleaning

Implementing preventive maintenance schedules is fundamental to keeping cleanroom lighting systems in optimal condition. Regular inspections and cleaning help identify and address potential issues before they escalate, ensuring consistent performance and compliance.

- Preventive Maintenance Schedules: Establishing a structured maintenance calendar is crucial. This schedule should outline the frequency of inspections, cleaning routines, and maintenance tasks based on the manufacturer's recommendations and operational demands. For instance, high-intensity UV-C lamps may require more frequent cleaning to prevent dust accumulation, which can impede disinfection efficacy.

- Inspection Protocols: Routine inspections should assess the physical condition of lighting fixtures, checking for signs of wear, corrosion, or damage. Inspectors should verify that all components, such as bulbs, ballasts, and reflectors, are functioning correctly and free from defects. Additionally, ensuring that fixtures are securely mounted prevents vibrations or movements that could disrupt lighting uniformity.

- Cleaning Procedures: Regular cleaning of lamps and fixtures is essential to maintain optimal light output and prevent microbial buildup. Cleaning protocols should specify the use of non-abrasive, chemical-free cleaners to avoid damaging sensitive components. For UV-C systems, ensuring that lamp surfaces are free from contaminants is critical for effective disinfection.

Component Replacement

Timely replacement of critical components is vital for sustaining the performance and compliance of cleanroom lighting systems.

- Lamp Replacement: UV-C and LED lamps have finite lifespans. Monitoring lamp usage hours and performance indicators helps determine the appropriate time for replacement. Degraded lamps emit reduced UV-C radiation, compromising disinfection efficacy and potentially leading to non-compliance with regulatory standards.

- Filter Maintenance: cleanrooms often incorporate filters, such as HEPA filters, to maintain air purity. Regular replacement or cleaning of these filters ensures that the lighting systems work in conjunction with effective air filtration, preventing particulate accumulation that could interfere with lighting performance.

- Fixture and Component Upgrades: Over time, components like ballasts, reflectors, and housing materials may degrade or become obsolete. Proactively upgrading these components ensures that lighting systems remain efficient and compliant with the latest standards. Using UV-resistant materials for fixtures can extend their lifespan and reduce the frequency of replacements.

B. Ongoing Validation and Requalification

Ongoing validation and requalification are essential for verifying that cleanroom lighting systems continue to meet FDA and ISO standards over time.

Periodic Performance Testing

Regular performance testing ensures that lighting systems operate within the specified parameters, maintaining compliance and effective disinfection.

- Installation Qualification (IQ): IQ involves verifying that lighting systems are installed correctly according to design specifications and manufacturer guidelines. This includes checking the placement, alignment, and connectivity of lighting fixtures within the cleanroom environment.

- Operational Qualification (OQ): OQ tests the functionality of lighting systems under normal operating conditions. This involves measuring light intensity (lux), uniformity, and energy consumption to ensure that they meet the required standards. For UV-C systems, OQ may also include testing the efficacy of microbial inactivation.

- Performance Qualification (PQ): PQ assesses the overall performance of lighting systems in real-world operational settings. This includes monitoring the systems over extended periods to confirm sustained compliance and effectiveness. PQ may involve biological testing to verify that UV-C disinfection targets are consistently achieved.

Impact of Process Changes

Any alterations to manufacturing processes or cleanroom layouts necessitate revalidating lighting systems to maintain compliance.

- Process Modifications: Changes in production workflows, such as the introduction of new equipment or shifts in material handling procedures, can affect lighting requirements. Revalidation ensures that lighting systems are appropriately adjusted to address new contamination risks and operational demands.

- cleanroom Layout Changes: Alterations to the physical layout of cleanrooms, including the addition of new workstations or reconfiguration of existing spaces, require reassessment of lighting placement and coverage. Ensuring that all areas remain adequately illuminated and free from shadowed zones is critical for ongoing compliance.

C. Troubleshooting Common Issues

Addressing lighting-related issues promptly is essential for maintaining compliance and ensuring the efficacy of cleanroom sanitation efforts.

Diagnosing Lighting Problems

Identifying and resolving issues related to lighting intensity, uniformity, and system failures is crucial for sustaining performance.

- Intensity Fluctuations: Variations in light intensity can indicate lamp degradation or electrical issues. Regular monitoring and immediate replacement of dimmed lamps prevent reduced disinfection efficacy.

- Uniformity Discrepancies: Inconsistent lighting distribution may result from misaligned fixtures, reflective surface buildup, or shadowed areas. Troubleshooting involves realigning fixtures, cleaning reflective surfaces, and ensuring that all areas receive adequate light exposure.

- System Failures: Electrical malfunctions or component failures can disrupt lighting systems. Diagnosing these issues requires a systematic approach, including checking electrical connections, inspecting control systems, and replacing faulty components to restore normal operation.

Read more: Key Considerations in Designing Cleanroom Lighting Systems

Addressing Compliance Failures

When deviations from standards are detected, implementing corrective actions is imperative to prevent recurring issues and maintain compliance.

- Root Cause Analysis: Conducting a thorough investigation to determine the underlying causes of compliance failures helps in devising effective corrective measures. This may involve examining maintenance practices, evaluating system design, or reassessing operational procedures.

- Corrective and Preventive Actions (CAPA): Developing and implementing CAPA plans address identified issues and prevent their recurrence. This includes adjusting maintenance schedules, upgrading lighting components, and enhancing training programs to reinforce best practices.

- Verification of Corrective Actions: After implementing CAPA, verifying their effectiveness through follow-up inspections and performance testing ensures that compliance is restored and sustained.

D. Documentation for Maintenance and Validation

Maintaining detailed records of all maintenance and validation activities is essential for demonstrating compliance and facilitating regulatory inspections.

Maintenance Logs

- Comprehensive maintenance logs provide a chronological record of all activities related to cleanroom lighting systems.

- Record-Keeping Practices: Documenting scheduled inspections, cleaning procedures, component replacements, and repairs ensures that all maintenance activities are tracked and can be reviewed during audits. These logs should include dates, descriptions of tasks performed, and the names of responsible personnel.

- Benefits of Maintenance Logs: Detailed logs support transparency and accountability, making it easier to identify patterns, track the effectiveness of maintenance practices, and demonstrate compliance with FDA and ISO standards during regulatory inspections.

Validation Reports

Validation reports document the results of performance testing and compliance verification, providing evidence that lighting systems meet required standards.

- Comprehensive Reporting: Validation reports should include detailed descriptions of testing methodologies, measurement results, and assessments of compliance with lighting specifications. For UV-C systems, reports may also include biological testing outcomes demonstrating microbial inactivation efficacy.

- Regulatory Documentation: These reports are critical during regulatory inspections, as they provide concrete evidence that lighting systems have been properly validated and continue to operate within defined parameters. Maintaining organized and accessible validation reports simplifies the audit process and reinforces the facility’s commitment to compliance and food safety.

- Continuous Improvement: Analyzing validation reports helps identify areas for improvement, guiding future maintenance and validation efforts to enhance lighting system performance and compliance.

VII. Challenges and Considerations

While ultraviolet-C (UV-C) lighting offers significant benefits for contamination control in food manufacturing cleanrooms, its implementation is not without challenges. Addressing these challenges is crucial to ensure the effective, safe, and economically viable use of UV-C technology. This section explores the key challenges and considerations associated with UV-C lighting in cleanrooms, including material compatibility, ensuring uniform coverage, safety and health risks, and financial implications such as initial investment and return on investment (ROI).

A. Material Compatibility and Potential Damage

UV-C Effects on Materials

Prolonged exposure to UV-C light can have detrimental effects on various materials commonly used in cleanrooms, such as plastics, textiles, and certain coatings. UV-C radiation is highly energetic and can break down chemical bonds within materials, leading to degradation over time. For instance, plastics like polycarbonate and acrylic may become brittle, discolored, or lose their structural integrity when subjected to continuous UV-C exposure. Textiles used in cleanroom garments can experience fiber weakening and loss of elasticity, compromising their protective capabilities. Additionally, adhesives and sealants may degrade, resulting in compromised seals and potential contamination ingress. These material degradations not only affect the longevity and functionality of cleanroom components but also pose risks to the overall cleanliness and safety of the environment.

Selecting UV-Resistant Materials

To mitigate the adverse effects of UV-C exposure, it is essential to select materials that are inherently resistant to UV-C radiation. UV-resistant plastics, such as certain grades of polypropylene and polyethylene, offer enhanced durability and maintain their physical properties despite prolonged UV-C exposure. For textiles, materials treated with UV stabilizers or inherently UV-resistant fibers should be chosen to ensure longevity and maintain protective functions. Moreover, sealants and adhesives specifically formulated to withstand UV-C exposure should be utilized to maintain airtight and contamination-proof seals. By carefully selecting UV-resistant materials, food production facilities can preserve the integrity and functionality of their cleanroom components, ensuring sustained contamination control and operational efficiency.

B. Ensuring Uniform Coverage

Airflow Dynamics

Achieving uniform UV-C exposure within a cleanroom is critical for effective disinfection. Complex airflow patterns can create areas of stagnation or turbulence, leading to inconsistent UV-C exposure and potential microbial hotspots. Understanding the dynamics of airflow within the cleanroom is essential for optimizing UV-C lamp placement and ensuring that all areas receive adequate disinfection. Computational Fluid Dynamics (CFD) simulations can be employed to model airflow patterns and identify optimal locations for UV-C fixtures. Additionally, balancing the HVAC (heating, ventilation, and air conditioning) system to promote steady and laminar airflow can enhance the uniformity of UV-C exposure, ensuring comprehensive contamination control across the entire cleanroom environment.

Fixture Design

The design of UV-C fixtures plays a pivotal role in maximizing coverage and minimizing shadowed areas where contaminants might persist. Fixtures should be strategically positioned to ensure that UV-C light reaches all surfaces and airflows within the cleanroom. Adjustable fixtures that allow for tilting and angling can help direct UV-C rays more effectively, reducing the likelihood of shadowed zones. Incorporating reflective surfaces and utilizing multiple lamp configurations can further enhance light distribution, ensuring that hard-to-reach areas receive sufficient UV-C exposure. Additionally, modular and scalable fixture designs enable easy adjustments and expansions as cleanroom layouts evolve, maintaining optimal disinfection efficacy over time.

C. UV-C Light Safety and Health Risks

Health Hazards

Despite its effectiveness in microbial inactivation, UV-C light poses significant health risks if proper safety measures are not implemented. Direct exposure to UV-C radiation can cause severe skin burns, known as erythema, and eye injuries, including photokeratitis and cataracts. These health hazards necessitate stringent safety protocols to protect workers from accidental UV-C exposure. The high energy of UV-C photons makes them particularly hazardous, as even brief exposure can result in immediate and long-term health consequences.

Mitigation Strategies

To safeguard workers, comprehensive protective measures and safety protocols must be established when implementing UV-C lighting in cleanrooms. Key strategies include:

- Protective Equipment (PPE): Workers should wear appropriate PPE, such as UV-resistant gloves, face shields, and protective eyewear, when operating or maintaining UV-C systems. PPE minimizes the risk of direct skin and eye exposure to UV-C radiation.

- Physical Barriers: Installing enclosed fixtures, UV-C shielding, and protective screens around UV-C lamps prevents accidental exposure to UV-C light. These barriers ensure that UV-C radiation remains confined to intended areas, protecting workers from unintended exposure.

- Warning Signage: Clearly visible signs indicating the presence of UV-C lighting and the associated hazards should be placed throughout the cleanroom to alert workers to potential risks. These signs reinforce the importance of adhering to safety protocols.

Training Programs: Comprehensive training on the safe use and maintenance of UV-C systems is essential. Workers should be educated on the dangers of UV-C exposure, proper handling procedures, and emergency response actions in case of accidental exposure. - Automated Shut-Off Systems: Implementing sensors and automated controls that detect human presence and deactivate UV-C lamps can further reduce the risk of accidental exposure. These systems ensure that UV-C lighting operates only when the cleanroom is secure and unoccupied.

D. Initial Investment and ROI

Cost Considerations

The initial investment required for implementing UV-C lighting systems in food production cleanrooms can be substantial. Costs include purchasing UV-C lamps and fixtures, integrating them with existing HVAC and automation systems, and conducting installation and validation procedures. Additionally, ongoing maintenance and component replacement add to the overall financial commitment. For many food manufacturers, especially small to medium-sized enterprises, these upfront costs can be a significant barrier to adoption. Evaluating the cost implications involves not only the direct expenses associated with purchasing and installing UV-C systems but also the indirect costs related to training staff, modifying infrastructure, and maintaining compliance documentation.

Return on Investment (ROI)

Despite the high initial costs, UV-C lighting offers substantial long-term cost savings that can offset the initial investment. Key factors contributing to a favorable ROI include:

- Reduced Chemical Usage: UV-C disinfection reduces the reliance on chemical disinfectants, which require regular purchase and disposal. This not only lowers material costs but also minimizes environmental impact and compliance costs associated with chemical handling.

- Lower Contamination Rates: Effective microbial control reduces the likelihood of contamination incidents, product recalls, and associated financial losses. By maintaining higher hygiene standards, UV-C lighting helps protect the manufacturer’s reputation and consumer trust, translating into sustained revenue and market competitiveness.

- Extended Equipment Lifespan: By minimizing microbial-induced corrosion and wear, UV-C lighting can extend the lifespan of cleanroom equipment and surfaces, reducing the frequency of repairs and replacements.

- Enhanced Product Shelf Life: Preventing spoilage and extending the shelf life of perishable goods can lead to increased sales and reduced waste, further enhancing profitability and sustainability.

- Energy Efficiency: Modern UV-C lighting systems, particularly LED-based solutions, are energy-efficient, resulting in lower operational costs over time. The energy savings contribute directly to the ROI by reducing utility expenses.

- Maintenance Cost Reduction: Durable and long-lasting UV-C components decrease the frequency of maintenance and replacement, further lowering ongoing operational costs.

In conclusion, while the initial investment in UV-C lighting systems can be significant, the long-term benefits in terms of cost savings, enhanced food safety, and operational efficiency provide a compelling case for their adoption in food production cleanrooms. By carefully evaluating both the upfront costs and the potential ROI, food manufacturers can make informed decisions that support both compliance and financial sustainability.

VIII. Best Practices for Compliance and Optimization

Achieving and maintaining compliance with FDA and ISO standards for cleanroom lighting in food manufacturing requires a strategic and multifaceted approach. Best practices encompass the development of comprehensive compliance programs, fostering continuous improvement through regular auditing, leveraging advanced technologies, and cultivating a culture of compliance within the organization. Implementing these best practices ensures not only adherence to regulatory standards but also enhances operational efficiency and food safety.

A. Developing Comprehensive Compliance Programs

Policy Development

Creating robust policies that underscore the importance of adhering to FDA and ISO standards is foundational to a successful compliance program. These policies should clearly outline the organization’s commitment to maintaining high standards of cleanliness and safety through effective lighting systems. Policies must detail the specific requirements for lighting intensity, uniformity, maintenance schedules, and sanitation protocols, ensuring that all employees understand their roles and responsibilities in upholding these standards. Additionally, policies should incorporate guidelines for regular review and updates to stay aligned with evolving regulations and technological advancements. By formalizing these commitments, organizations establish a clear framework that prioritizes compliance and sets the standard for operational practices.

Cross-Functional Teams

Establishing cross-functional teams that include members from quality assurance, engineering, and operations is crucial for overseeing compliance efforts. These teams facilitate collaboration and ensure that all aspects of cleanroom lighting are addressed comprehensively. Quality assurance personnel can monitor compliance with regulatory standards, engineers can focus on the technical aspects of lighting systems, and operations staff can ensure that lighting practices integrate smoothly into daily workflows. This multidisciplinary approach fosters a holistic understanding of compliance requirements and enables the team to respond swiftly to any issues that arise. By leveraging the diverse expertise of team members, organizations can develop more effective compliance strategies and ensure sustained adherence to FDA and ISO standards.

B. Continuous Improvement and Auditing

Regular Audits

Conducting regular internal and external audits is essential for assessing compliance with FDA and ISO standards. Internal audits allow organizations to proactively identify and rectify potential non-compliance issues before they attract regulatory scrutiny. These audits should systematically evaluate all aspects of cleanroom lighting, including installation, operation, maintenance, and documentation practices. External audits, conducted by third-party assessors, provide an unbiased evaluation of compliance and help validate the effectiveness of internal controls. Regular auditing not only ensures ongoing adherence to standards but also highlights areas for improvement, fostering a culture of accountability and continuous enhancement.

Feedback Loops

Implementing robust feedback loops is critical for driving continuous improvement based on audit findings and performance data. Feedback mechanisms should enable the collection of insights from audits, inspections, and operational performance metrics, which can then be analyzed to identify trends and recurring issues. This information should inform the development of corrective and preventive actions (CAPA), ensuring that lessons learned are applied to enhance lighting systems and compliance practices. By establishing a cycle of continuous feedback and improvement, organizations can adapt to changing conditions, address emerging risks, and maintain high standards of cleanliness and safety.

C. Leveraging Technology for Enhanced Compliance

Advanced Monitoring Systems

Utilizing Internet of Things (IoT)-enabled sensors and automated systems revolutionizes the monitoring and control of cleanroom lighting. These advanced monitoring systems provide real-time data on lighting intensity, uniformity, and operational status, enabling immediate detection of deviations from compliance standards. Automated controls can adjust lighting parameters dynamically based on environmental conditions, ensuring consistent performance and minimizing the risk of non-compliance. Additionally, integration with centralized management platforms allows for seamless oversight and rapid response to any issues, enhancing the reliability and effectiveness of cleanroom lighting systems.

Data Analytics

Employing data analytics to track performance metrics, identify trends, and predict maintenance needs is a powerful tool for optimizing compliance and operational efficiency. By analyzing historical data on lighting performance, organizations can identify patterns that indicate potential issues, such as gradual declines in light intensity or recurring maintenance needs. Predictive analytics can forecast when components are likely to fail, enabling proactive maintenance and reducing downtime. Furthermore, data-driven insights support informed decision-making, allowing organizations to optimize lighting configurations and improve overall system performance. Leveraging data analytics ensures that cleanroom lighting remains compliant, efficient, and responsive to the dynamic needs of food manufacturing processes.

D. Fostering a Culture of Compliance

Employee Engagement

Encouraging active employee involvement and accountability is fundamental to maintaining compliance with cleanroom lighting standards. Engaging employees through comprehensive training and awareness programs ensures that they understand the importance of compliance and their specific roles in achieving it. Empowering staff to take ownership of their responsibilities fosters a proactive approach to contamination control and lighting maintenance. Regular training sessions, workshops, and informational materials keep employees informed about the latest standards, best practices, and technological advancements, reinforcing their commitment to maintaining a compliant and safe work environment.

Recognition and Rewards