Cleanroom lighting plays a crucial role in maintaining environmental control and ensuring optimal visibility for delicate activities. This article delves into the key aspects of cleanroom lighting, including its functionalities, applications, classification, and cost considerations.

1. Defining Cleanroom Lighting:

Cleanroom lights are specialized luminaires designed to illuminate controlled environments while minimizing particle emission and contamination. They achieve this through meticulous engineering, material selection, and rigorous adherence to cleanroom standards.

2. Diverse Applications:

Cleanroom lights find extensive application in various sectors demanding stringent environmental control, such as:

- Pharmaceutical production: Ensuring product sterility and safety during medication manufacturing.

- Microelectronics assembly: Facilitating precise and meticulous work on sensitive electronic components.

- Medical facilities: Maintaining aseptic conditions in operating rooms and laboratories.

- Scientific research: Providing optimal lighting for critical scientific experiments.

3. Sourcing and Considerations:

While cleanroom lights are sourced from multiple countries, China currently holds a dominant position due to its:

- Geographical proximity: Facilitating cost-effective logistics and supply chains.

- Manufacturing prowess: Established infrastructure and expertise in luminaire production.

However, cost shouldn't overshadow quality. Factors like:

- Compliance with international standards (ISO 14644): Ensuring adherence to stringent cleanroom regulations.

- Material composition and construction: Opting for materials that minimize particle shedding and facilitate disinfection.

- Light emission characteristics: Selecting appropriate color temperature and flicker control for visual comfort and accuracy.

4. Classification and Design Optimization:

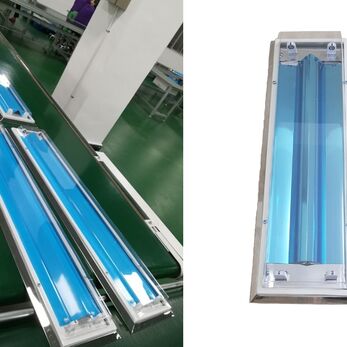

Cleanroom lights fall into two broad categories:

- Cleanroom light fixtures: Offering versatility and ease of maintenance with options for surface or recessed mounting.

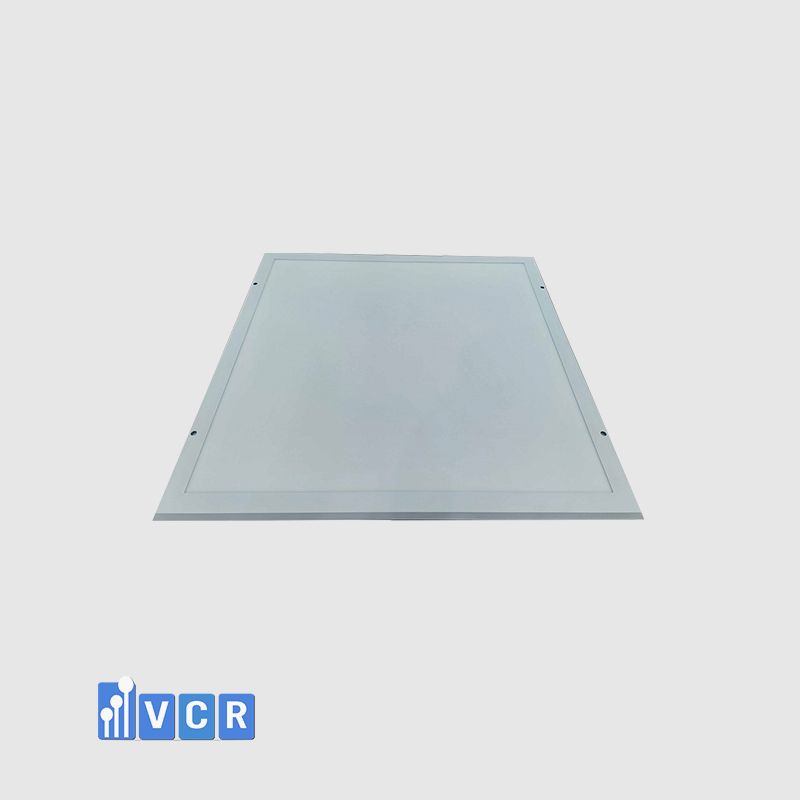

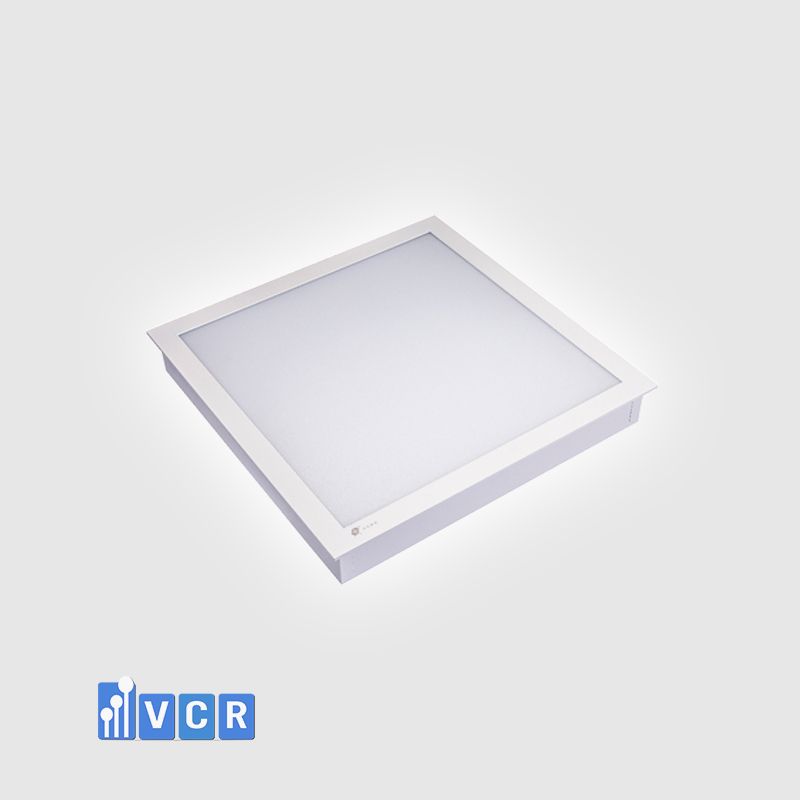

- LED panel lights: Delivering energy efficiency and uniform illumination, often in flush-mounted configurations.

A key differentiator for cleanroom lights is their beveled edges and corners, minimizing dust accumulation and facilitating cleaning. This feature readily distinguishes them from regular luminaires.

5. Cost Analysis and Implications:

Generally, LED panel lights command a higher price point compared to light fixtures of similar size due to their advanced technology and performance characteristics. Cost variations within each category depend on factors like:

- Size and wattage: Larger and higher-wattage lights typically incur higher costs.

- Brand and manufacturing quality: Reputable brands with stringent quality control measures may come at a premium.

Choosing the right cleanroom light requires careful consideration of both initial cost and long-term implications. Incorrect decisions can lead to costly replacements due to inadequate performance or non-compliance with cleanroom standards.

Conclusion:

Cleanroom lighting is a multifaceted domain demanding a scientific approach. By understanding its functionalities, applications, classification, and cost considerations, stakeholders can make informed decisions to secure optimal illumination and environmental control in sensitive settings.

Reference: