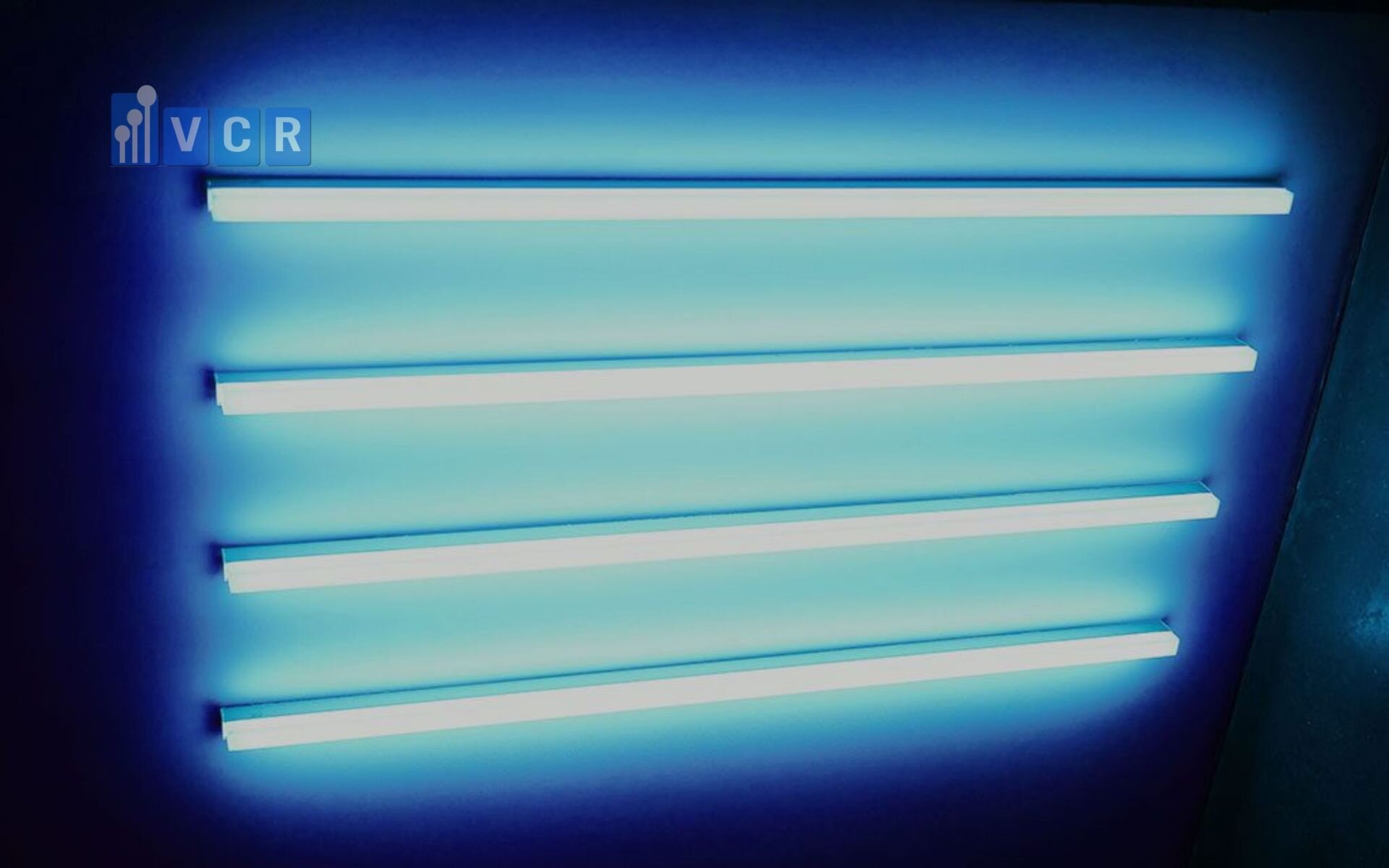

UV-C lighting is revolutionizing food production cleanrooms by enhancing hygiene and safety standards. Learn how UV-C technology effectively eliminates harmful microorganisms, ensures product quality, and complies with industry regulations.

Summaries

Discover the benefits and best practices for installing and maintaining UV-C lighting to optimize your cleanroom operations today! Join VCR Clean Room Equipment to learn about UV-C Lighting in Food Production Clean Rooms: Benefits and Best Practices

I. Introduction UV-C Lighting

In the ever-evolving landscape of food production, ensuring the highest standards of safety and quality is paramount. Central to achieving these standards are clean rooms, specialized environments meticulously designed to minimize contamination and maintain stringent hygiene protocols. Clean rooms play a crucial role in various stages of food manufacturing, from the handling of raw ingredients to the packaging of finished products. By controlling environmental factors such as airborne particles, temperature, and humidity, clean rooms help prevent the introduction and proliferation of contaminants, thereby safeguarding both the integrity of the food products and the health of consumers.

Clean rooms are defined as controlled environments with low levels of pollutants, such as dust, airborne microbes, aerosol particles, and chemical vapors. These spaces are equipped with advanced filtration systems, including High-Efficiency Particulate Air (HEPA filters), which remove particles as small as 0.3 microns with 99.97% efficiency. In the context of food manufacturing, clean rooms are indispensable for processes that require high levels of sanitation and contamination control. For instance, the production of ready-to-eat meals, dairy products, and baked goods often takes place within clean rooms to ensure that the final products are free from harmful microorganisms and contaminants that could compromise quality and safety.

The importance of clean rooms in food manufacturing cannot be overstated. Contamination can occur at any stage of the production process, from the initial handling of raw materials to the final packaging of products. Clean rooms provide a controlled environment that significantly reduces the risk of contamination by maintaining strict hygiene standards. This is achieved through a combination of architectural design, air filtration systems, and rigorous operational protocols. By preventing the ingress of contaminants and controlling internal environmental conditions, clean rooms help manufacturers produce safe, high-quality food products that meet both regulatory standards and consumer expectations.

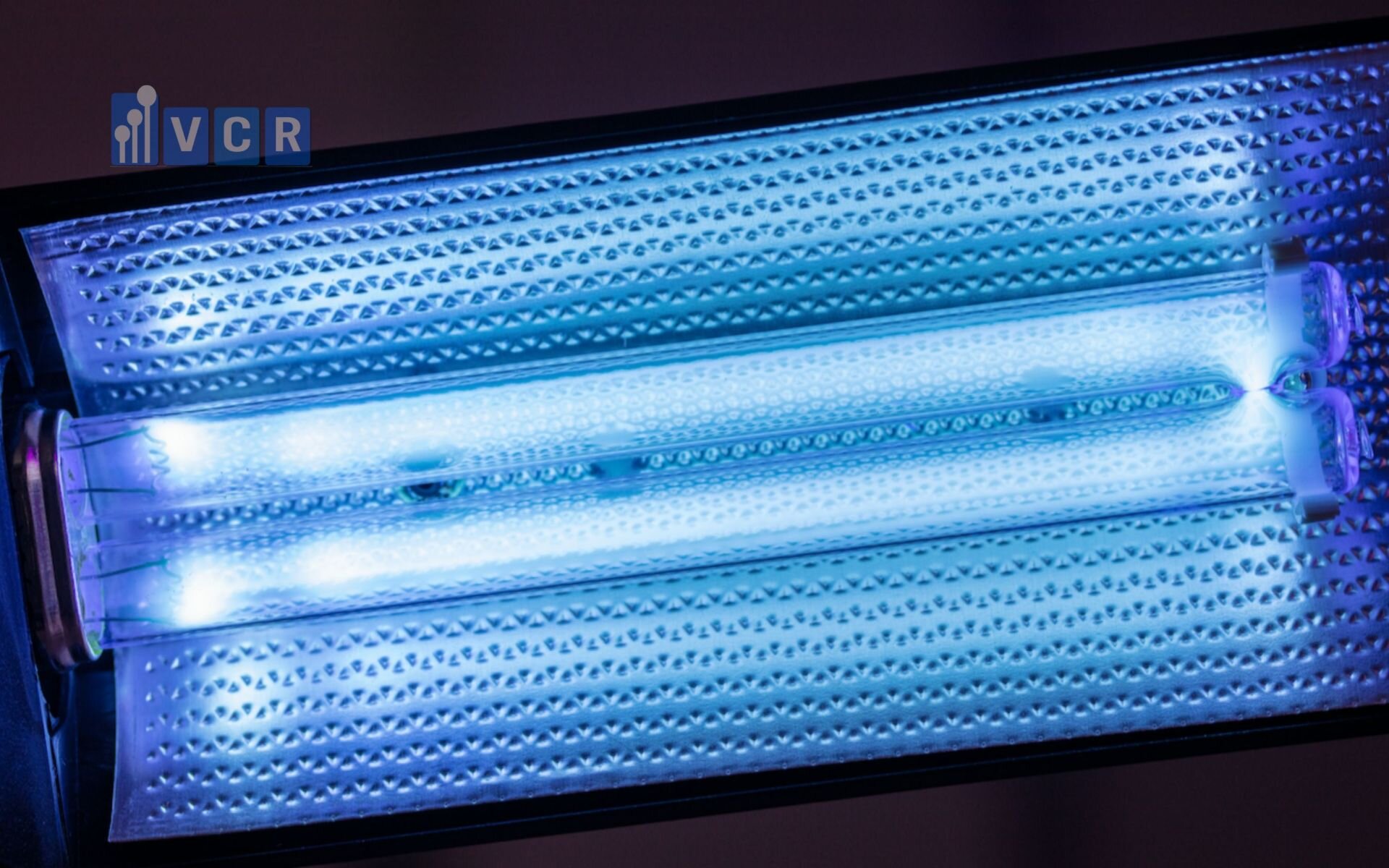

Amidst the array of technologies employed to maintain cleanliness and safety in food production, UV-C lighting has emerged as a powerful tool for enhancing contamination control within clean rooms. Ultraviolet-C (UV-C) light, with its wavelength range of 200 to 280 nanometers, possesses potent disinfecting properties that make it highly effective in inactivating a broad spectrum of microorganisms, including bacteria, viruses, and fungi. UV-C light disrupts the DNA and RNA of these pathogens, rendering them unable to reproduce and effectively neutralizing their threat.

The historical use of UV-C in industry dates back several decades, where it has been utilized in various sectors such as healthcare, water treatment, and air purification. In the realm of food production, UV-C lighting has been increasingly integrated into clean room environments to bolster existing sanitation measures. Initially adopted for its ability to sterilize surfaces and equipment, UV-C technology has evolved with advancements in lamp efficiency and safety features, making it a versatile and indispensable component of modern clean room designs.

This essay aims to explore the benefits and best practices of implementing UV-C lighting in food production clean rooms. By delving into the scientific principles underlying UV-C disinfection, assessing its efficacy in reducing microbial contamination, and outlining the optimal strategies for its deployment, this discussion seeks to provide a comprehensive understanding of how UV-C lighting can enhance food safety and quality. Additionally, the essay will examine the integration of UV-C systems with other sanitation technologies, address potential challenges and safety considerations, and highlight case studies demonstrating successful implementations.

The structure of this essay is organized as follows: after the introduction, Section II will provide a detailed understanding of UV-C lighting, including its mechanisms and applications. Section III will discuss the various benefits of UV-C lighting in food production clean rooms, while Section IV will outline the best practices for its implementation. Section V will address maintenance and validation strategies to ensure the continued effectiveness of UV-C systems, and Section VI will present case studies and real-world applications. Finally, Section VII will conclude with a summary of key insights and future trends in UV-C technology for food production clean rooms.

Through this comprehensive exploration, the essay underscores the pivotal role of UV-C lighting in advancing food safety protocols and enhancing the operational excellence of clean rooms within the food manufacturing industry.

II. Understanding UV-C Lighting

Ultraviolet-C (UV-C) lighting has emerged as a pivotal technology in enhancing sanitation and contamination control within food production clean rooms. This section delves into the fundamental aspects of UV-C lighting, including its scientific basis, mechanisms of disinfection, and the various types of UV-C lamps and equipment utilized in the food manufacturing industry.

A. What is UV-C?

Scientific Basis

Ultraviolet-C (UV-C) light is a segment of the ultraviolet spectrum with wavelengths ranging from 200 to 280 nanometers (nm). It is renowned for its potent antimicrobial properties, making it an invaluable tool in sterilization and disinfection processes. UV-C light is typically generated using specialized lamps, such as low-pressure mercury lamps, medium-pressure lamps, and emerging UV-C LED technologies. These lamps emit high-intensity UV-C radiation that penetrates microbial cells, disrupting their structural integrity and rendering them inactive.

The generation of UV-C light involves exciting mercury vapor within the lamp, which then emits UV-C photons as the mercury atoms return to their ground state. Advances in UV-C technology have led to the development of more efficient and durable lamps, enhancing their applicability in various industrial settings, including food production clean rooms. The antimicrobial efficacy of UV-C light stems from its ability to cause direct damage to the DNA and RNA of microorganisms, preventing their replication and ensuring effective disinfection.

Mechanism of Action

The antimicrobial action of UV-C light is primarily attributed to its interaction with the nucleic acids of microorganisms. When UV-C photons are absorbed by the DNA and RNA molecules within bacteria, viruses, fungi, and spores, they induce structural alterations that disrupt the genetic material. This disruption prevents the microorganisms from replicating and performing essential cellular functions, ultimately leading to their inactivation.

UV-C light operates through a non-thermal mechanism, meaning it does not rely on heat to achieve disinfection. Instead, the energy from UV-C photons is directly absorbed by the microbial DNA and RNA, causing molecular bonds to break and leading to mutations or the formation of thymine dimers. These molecular damages are irreversible, ensuring that the microorganisms cannot survive or proliferate. Consequently, UV-C lighting serves as an effective and environmentally friendly disinfection method that complements traditional chemical sanitizers and physical cleaning protocols in food production environments.

B. Mechanism of UV-C Disinfection

DNA/RNA Damage

The disinfection efficacy of UV-C light is fundamentally rooted in its ability to cause substantial genetic damage to microorganisms. When UV-C photons penetrate microbial cells, they are absorbed by the DNA and RNA strands, inducing the formation of covalent bonds between adjacent thymine bases—a phenomenon known as thymine dimerization. These thymine dimers distort the DNA/RNA structure, leading to errors during replication and transcription processes. As a result, the affected microorganisms are unable to reproduce or carry out vital cellular functions, effectively rendering them inactive and preventing the spread of contamination.

In addition to thymine dimerization, UV-C light can cause other forms of DNA/RNA damage, such as the formation of pyrimidine-pyrimidone (6-4) photoproducts and strand breaks. These molecular alterations further inhibit the ability of microorganisms to repair their genetic material, ensuring the permanence of the disinfection effect. The cumulative impact of these genetic damages ensures that UV-C disinfection is both rapid and thorough, making it a reliable method for maintaining hygiene standards in food production clean rooms.

Effectiveness Against Various Pathogens

UV-C light exhibits broad-spectrum antimicrobial activity, making it effective against a wide range of pathogens commonly encountered in food production environments. Its efficacy spans across various types of microorganisms, including:

Bacteria: UV-C light is highly effective in inactivating both Gram-positive and Gram-negative bacteria. Pathogens such as Escherichia coli, Salmonella spp., and Listeria monocytogenes are susceptible to UV-C-induced DNA damage, ensuring their elimination from critical processing areas.

Viruses: Enveloped and non-enveloped viruses, including norovirus and hepatitis A, are inactivated by UV-C light. The ability of UV-C to disrupt viral RNA and DNA renders these viruses non-infectious, thereby preventing viral contamination of food products.

Fungi and Molds: UV-C light effectively inactivates various fungal species and molds that can spoil food products and create health hazards. By targeting the genetic material of these organisms, UV-C ensures their suppression and eradication from clean room environments.

Spores: While bacterial spores are more resistant to UV-C light compared to vegetative cells, prolonged exposure or higher doses of UV-C can effectively inactivate spore-forming bacteria such as Bacillus cereus and Clostridium botulinum. This ensures comprehensive contamination control, even against resilient microbial forms.

The versatility of UV-C lighting in targeting diverse pathogens underscores its significance in maintaining the stringent hygiene standards required in food production clean rooms. By effectively reducing microbial loads, UV-C light plays a critical role in ensuring food safety, extending product shelf life, and enhancing overall operational efficiency.

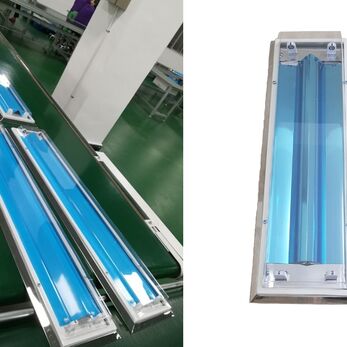

C. Types of UV-C Lamps and Equipment

Low-Pressure vs. Medium-Pressure UV-C Lamps

UV-C lighting systems are categorized based on the type of lamps used, with low-pressure and medium-pressure lamps being the most prevalent in industrial applications.

Low-Pressure UV-C Lamps: These lamps operate at a low pressure, typically around 0.3 atmospheres, and emit UV-C light predominantly at a wavelength of 254 nm. Low-pressure lamps are highly efficient at producing germicidal UV-C radiation and are commonly used for surface disinfection and air purification in clean rooms. Their monochromatic output ensures targeted microbial inactivation, making them ideal for environments where precise contamination control is essential.

Medium-Pressure UV-C Lamps: Operating at higher pressures, medium-pressure lamps emit a broader spectrum of UV-C wavelengths, ranging from 200 to 300 nm. This broader emission enhances their ability to inactivate a wider array of microorganisms, including those that are more resistant to specific wavelengths. Medium-pressure lamps are often used in applications requiring higher disinfection capacities, such as large-scale air handling systems and integrated clean room sanitization processes.

The choice between low-pressure and medium-pressure UV-C lamps depends on the specific disinfection requirements, environmental conditions, and the types of pathogens targeted within the food production clean room.

LED UV-C Technology

Advancements in UV-C LED technology have introduced new possibilities for disinfection applications, offering several advantages over traditional mercury-based UV-C lamps.

Emerging Advancements: UV-C LEDs emit light at precise wavelengths within the UV-C spectrum, allowing for targeted microbial inactivation with greater energy efficiency. The development of high-power UV-C LEDs has increased their applicability in industrial settings, making them a viable alternative to conventional UV-C lamps.

Benefits: UV-C LEDs offer longer lifespans, faster start-up times, and lower energy consumption compared to mercury lamps. Their compact size and modularity enable flexible installation options, allowing for easy integration into existing clean room infrastructures. Additionally, UV-C LEDs eliminate the use of hazardous materials, such as mercury, enhancing their environmental sustainability and safety.

While UV-C LED technology is still evolving, its potential for scalable and customizable disinfection solutions makes it an attractive option for future clean room applications in the food production industry.

Integration with Clean Room Systems

Integrating UV-C lighting into existing clean room systems requires careful planning and design to maximize disinfection efficacy and maintain operational harmony.

Air Handling Units (AHUs): UV-C lamps can be installed within AHUs to disinfect incoming and recirculating air, ensuring that airborne contaminants are neutralized before entering the clean room. This integration helps maintain a sterile environment by continuously purifying the air supply.

Surface Disinfection Fixtures: UV-C lamps can be strategically placed within the clean room to disinfect surfaces, equipment, and tools. Automated UV-C fixtures mounted on ceilings or walls ensure comprehensive coverage, minimizing the risk of surface contamination.

Automation and Control Systems: Integrating UV-C equipment with automated control systems, such as Supervisory Control and Data Acquisition (SCADA) systems, enables real-time monitoring and management of UV-C disinfection processes. Automated scheduling, intensity adjustments, and maintenance alerts enhance the reliability and efficiency of UV-C systems within clean rooms.

Effective integration of UV-C lighting with clean room systems ensures that disinfection processes are seamless, consistent, and capable of maintaining the high hygiene standards required in food production environments.

III. Benefits of UV-C Lighting in Food Production Clean Rooms

Ultraviolet-C (UV-C) lighting has revolutionized contamination control strategies within food production clean rooms, offering a multitude of benefits that enhance food safety, operational efficiency, and regulatory compliance. By leveraging the potent antimicrobial properties of UV-C light, food manufacturers can achieve superior sanitation outcomes, reduce microbial loads, and maintain the highest standards of hygiene. This section explores the comprehensive benefits of UV-C lighting, highlighting its role in contamination control, microbial reduction, synergy with other sanitation methods, energy efficiency, cost-effectiveness, food safety improvement, and regulatory compliance support.

A. Enhanced Contamination Control

Reduction of Microbial Load

One of the foremost advantages of UV-C lighting in food production clean rooms is its ability to significantly decrease both airborne and surface contaminants. UV-C light effectively inactivates a broad spectrum of microorganisms, including bacteria, viruses, fungi, and spores, by disrupting their genetic material. This reduction in microbial load is crucial in preventing the proliferation of pathogens that can compromise food safety and quality. By consistently lowering the presence of harmful microorganisms, UV-C lighting ensures a cleaner and safer production environment, thereby minimizing the risk of contamination incidents that could lead to product recalls or health hazards.

Prevention of Cross-Contamination

Cross-contamination poses a significant threat in food manufacturing, especially in environments handling multiple products or ingredients with varying allergen profiles. UV-C lighting aids in minimizing the spread of pathogens between different areas within a clean room by ensuring that air and surfaces remain free from viable microorganisms. This is particularly important in facilities where strict segregation of processes is necessary to prevent allergen cross-contact or contamination of sensitive products. By maintaining a consistently sanitized environment, UV-C lighting supports the integrity of compartmentalized production lines, thereby safeguarding both product quality and consumer health.

B. Reduction of Microbial Load

Airborne Pathogens

Airborne pathogens are a persistent challenge in food production clean rooms, as they can easily disperse and contaminate products and surfaces. UV-C lighting systems integrated into air handling units (AHUs) or installed as standalone fixtures are highly effective in purifying the air by inactivating microorganisms as they circulate through the clean room. This continuous purification process ensures that the air remains free from harmful pathogens, thereby maintaining a sterile environment conducive to safe food production. The ability of UV-C light to neutralize airborne bacteria and viruses contributes significantly to reducing the overall microbial load, enhancing the cleanliness and safety of the production area.

Surface Sanitization

Maintaining contaminant-free surfaces is essential in preventing microbial adherence and growth, which can lead to food spoilage and safety issues. UV-C lighting provides an efficient means of surface sanitization by directly targeting and inactivating microorganisms on equipment, workstations, and other critical surfaces within the clean room. Unlike chemical disinfectants, UV-C light offers a residue-free and environmentally friendly method of surface decontamination, reducing the need for frequent chemical applications and minimizing potential chemical residues on food-contact surfaces. This ensures that surfaces remain hygienic and safe for contact with food products, thereby upholding stringent hygiene standards.

C. Complementary to Other Sanitation Methods

Integration with Chemical Cleaners

While UV-C lighting is highly effective on its own, its integration with chemical cleaners can significantly enhance overall sanitation efficacy. Chemical disinfectants can target a wider range of contaminants and provide a residual antimicrobial effect, while UV-C light offers immediate and thorough microbial inactivation without leaving any residues. By combining UV-C disinfection with chemical cleaning protocols, food manufacturers can achieve a synergistic effect that ensures comprehensive contamination control. This integrated approach not only maximizes pathogen reduction but also addresses diverse microbial challenges, creating a more robust and reliable sanitation system within clean rooms.

Synergy with Physical Cleaning

Physical cleaning methods, such as wiping and scrubbing surfaces, are fundamental to maintaining cleanliness in food production environments. When combined with UV-C lighting, these physical methods can achieve higher levels of sanitation. Physical cleaning removes visible debris and organic matter that can shield microorganisms from UV-C exposure, ensuring that the subsequent UV-C treatment is more effective. Additionally, UV-C light can reach areas that might be difficult to access through manual cleaning alone, providing an extra layer of disinfection. This combination of physical and UV-C cleaning methods results in a more comprehensive and effective sanitation process, enhancing the overall hygiene and safety of the clean room.

D. Energy Efficiency and Cost-Effectiveness

Lower Energy Consumption

Compared to traditional lighting and disinfection methods, UV-C lighting systems are often more energy-efficient. LED-based UV-C lamps, in particular, consume significantly less power while providing the same or even superior disinfection capabilities. The high energy efficiency of UV-C LEDs translates to lower operational costs and reduced energy consumption, making them a sustainable choice for long-term sanitation needs. Additionally, advancements in UV-C technology have led to the development of more efficient lamps that deliver higher output with minimal energy usage, further enhancing their appeal from an energy conservation standpoint.

Long-Term Cost Savings

Implementing UV-C lighting in clean rooms can lead to substantial long-term cost savings for food manufacturers. By reducing the reliance on chemical disinfectants, which require regular purchase and disposal, UV-C systems help lower material costs and minimize waste management expenses. Moreover, the durability and longevity of UV-C lamps, especially LED variants, reduce the frequency of replacements and maintenance interventions, further decreasing operational costs. The enhanced microbial control provided by UV-C lighting also translates to fewer contamination incidents, reducing costs associated with product recalls, regulatory penalties, and lost consumer trust. Overall, the initial investment in UV-C lighting systems is offset by the significant cost savings realized through improved sanitation and operational efficiencies.

E. Improving Food Safety and Extending Shelf Life

Pathogen Control

Effective pathogen control is fundamental to ensuring the safety of food products. UV-C lighting plays a critical role in achieving this by inactivating a wide range of microorganisms that can cause foodborne illnesses. By consistently reducing the presence of harmful pathogens in the clean room environment, UV-C lighting helps prevent contamination of food products at various stages of production. This proactive approach to microbial control not only protects consumers from potential health risks but also enhances the overall safety profile of the food manufacturer, fostering greater consumer confidence and brand loyalty.

Product Quality Preservation

Beyond pathogen control, UV-C lighting contributes to the preservation of product quality by preventing spoilage and extending the shelf life of perishable goods. Microbial contamination can lead to the degradation of food products, resulting in off-flavors, odors, and textures that compromise their marketability. By maintaining a sterile environment and minimizing microbial load, UV-C lighting helps preserve the sensory and nutritional qualities of food products, ensuring that they remain fresh and appealing for longer periods. This extension of shelf life not only reduces food waste but also enhances the profitability and sustainability of food manufacturing operations.

F. Regulatory Compliance Support

Meeting Food Safety Standards

Compliance with food safety standards is non-negotiable for food manufacturers, as it ensures the protection of public health and avoids legal repercussions. UV-C lighting assists in meeting stringent regulatory requirements set forth by authorities such as the Food and Drug Administration (FDA), the United States Department of Agriculture (USDA), and international bodies like ISO and GFSI. These regulations often mandate robust contamination control measures, including effective disinfection protocols, which UV-C lighting can fulfill comprehensively. By integrating UV-C systems into their sanitation strategies, food manufacturers can demonstrate adherence to these standards, ensuring that their products meet the necessary safety and quality benchmarks required for market approval and consumer trust.

Documentation and Traceability

Consistent and thorough documentation is essential for regulatory compliance and traceability in food production. UV-C lighting systems facilitate this by providing reliable and standardized disinfection processes that can be easily documented and validated. Automated UV-C systems often come equipped with monitoring and logging capabilities that record operational parameters such as exposure times, intensity levels, and maintenance activities. These records are invaluable during audits and inspections, as they provide concrete evidence of compliance with regulatory standards and internal sanitation protocols. Furthermore, the traceability offered by UV-C documentation ensures that any contamination incidents can be swiftly traced back to their source, enabling prompt corrective actions and minimizing the impact on product safety and quality.

IV. Best Practices for Implementing UV-C Lighting

Implementing UV-C lighting in food production clean rooms requires a strategic approach to maximize its effectiveness while ensuring safety and compliance. Adhering to best practices during installation, dosage calibration, maintenance, safety measures, system integration, and staff training is essential for achieving optimal disinfection outcomes. This section outlines the key best practices for successfully integrating UV-C lighting into food production clean rooms, focusing on proper installation and placement, dosage and exposure time, maintenance and monitoring, safety measures and worker protection, integration with existing clean room systems, and training and Standard Operating Procedures (SOPs).

A. Proper Installation and Placement

Strategic Positioning Định vị chiến lược

The effectiveness of UV-C lighting largely depends on the strategic positioning of lamps within the clean room. Optimal placement ensures maximum coverage and efficient disinfection of both airborne pathogens and surface contaminants. Key considerations include:

Ceiling Mounts: Installing UV-C lamps on the ceiling provides broad coverage, targeting airborne particles and surfaces below. This placement is particularly effective for purifying the air and disinfecting large horizontal surfaces like countertops and machinery.

Wall Mounts and Fixtures: Additional lamps can be strategically placed on walls or integrated into existing fixtures to cover shadowed areas and hard-to-reach surfaces. This comprehensive coverage prevents any blind spots where contaminants might persist.

Air Handling Units (AHUs): Integrating UV-C lamps within AHUs ensures continuous disinfection of recirculating air, reducing the microbial load before the air enters the clean room. This placement is crucial for maintaining a sterile environment by targeting airborne pathogens effectively.

Avoiding Shadowed Areas

Ensuring that all surfaces and airflow pathways are adequately exposed to UV-C light is critical for comprehensive disinfection. Shadowed areas can harbor contaminants, undermining the efficacy of the UV-C system. Best practices to avoid shadowed areas include:

Multiple Lamp Configurations: Utilizing multiple UV-C lamps from different angles can eliminate shadowed zones, ensuring that every surface receives sufficient UV-C exposure. Overlapping coverage from various lamp positions guarantees that microorganisms on all surfaces are targeted.

Reflective Surfaces: Incorporating reflective materials around UV-C fixtures can help disperse UV-C light more evenly, reducing shadowed areas. Reflective surfaces enhance the distribution of UV-C photons, increasing the overall disinfection coverage.

Fixture Design: Selecting UV-C fixtures with adjustable angles and beam spreads allows for precise control over light distribution. Adjustable fixtures can be repositioned as needed to address specific contamination risks and adapt to changes in clean room layouts.

B. Dosage and Exposure Time

UV-C Dosage Calculation

Determining the correct intensity and exposure duration of UV-C light is essential for effective disinfection. The UV-C dosage is a function of both the UV-C intensity (measured in microwatts per square centimeter, μW/cm²) and the exposure time (measured in seconds). Key steps in dosage calculation include:

Assessing Pathogen Sensitivity: Different microorganisms require varying UV-C doses for effective inactivation. Understanding the susceptibility of target pathogens informs the required dosage levels.

Environmental Factors: Factors such as room size, lamp intensity, and airflow rates influence the UV-C dosage. Accurate calculations must account for these variables to ensure consistent disinfection.

Mathematical Models: Utilizing mathematical models and software tools can aid in calculating the appropriate UV-C dosage based on empirical data and theoretical principles. These models consider factors like UV-C absorption rates and pathogen inactivation kinetics to provide precise dosage recommendations.

Compliance with Standards

Adhering to industry guidelines and standards for UV-C exposure levels is crucial for ensuring both efficacy and safety. Key considerations include:

Regulatory Guidelines: Complying with regulations set forth by bodies such as the Food and Drug Administration (FDA) and the International Organization for Standardization (ISO) ensures that UV-C systems meet minimum safety and performance criteria.

Exposure Limits: Establishing exposure limits that protect workers from harmful UV-C radiation is essential. These limits dictate the maximum allowable UV-C intensity and exposure duration to prevent adverse health effects.

Validation and Verification: Conducting thorough validation and verification processes ensures that the UV-C system operates within the specified dosage parameters. Regular testing and calibration of UV-C lamps help maintain compliance with established standards.

C. Maintenance and Monitoring

Regular Maintenance Schedules

Maintaining UV-C lighting systems requires consistent and proactive maintenance to ensure their continued effectiveness and longevity. Key maintenance practices include:

Cleaning Lamps and Fixtures: Regular cleaning of UV-C lamps and fixtures prevents the accumulation of dust, debris, and contaminants that can block UV-C photons and reduce disinfection efficacy. Cleaning schedules should be based on usage patterns and environmental conditions.

Replacing Bulbs: UV-C lamps degrade over time, resulting in diminished UV-C output. Establishing a routine schedule for bulb replacement based on manufacturer recommendations and operational hours ensures that the system maintains its intended disinfection capacity.

Inspecting Components: Routine inspections of all UV-C system components, including reflectors, housings, and electrical connections, help identify and address wear and tear or potential failures before they impact system performance.

Performance Monitoring

Continuous monitoring of UV-C system performance is essential for maintaining effective disinfection and identifying any operational issues promptly. Key monitoring practices include:

Using Sensors and Data Logging: Integrating sensors that measure UV-C intensity, exposure time, and environmental conditions provides real-time data on system performance. Data logging facilitates trend analysis and early detection of performance deviations.

Automated Alerts: Implementing automated alert systems that notify operators of any irregularities or malfunctions ensures that corrective actions can be taken swiftly to maintain disinfection efficacy.

Periodic Testing: Conducting regular testing of UV-C output and disinfection effectiveness through biological indicators or surrogate markers validates the ongoing performance of the system. These tests confirm that the UV-C lighting continues to meet disinfection objectives.

D. Safety Measures and Worker Protection

Protective Equipment

Ensuring the safety of workers is paramount when implementing UV-C lighting in clean rooms. Proper protective equipment (PPE) and safety protocols help prevent accidental UV-C exposure, which can cause skin burns and eye injuries. Key safety measures include:

Personal Protective Equipment (PPE): Workers should wear appropriate PPE, such as UV-resistant gloves, face shields, and protective eyewear, when operating or maintaining UV-C systems. PPE minimizes the risk of direct skin and eye exposure to UV-C radiation.

Shielding and Barriers: Installing physical barriers, such as enclosed fixtures or protective screens, around UV-C lamps prevents accidental exposure to UV-C light. These barriers ensure that UV-C radiation remains confined to intended areas, protecting workers from unintended exposure.

Safety Protocols

Implementing comprehensive safety protocols is essential for preventing accidental UV-C exposure and ensuring a safe working environment. Key safety protocols include:

Interlock Systems: Installing interlock systems that automatically shut off UV-C lamps when doors are opened or unauthorized access is detected prevents accidental exposure. These systems ensure that UV-C lighting operates only when the clean room is secure and unoccupied.

Warning Signage: Clearly visible warning signs indicating the presence of UV-C lighting alert workers to potential hazards and promote safe behavior around UV-C systems. These signs reinforce the importance of adhering to safety protocols.

Emergency Shutdown Procedures: Establishing and training staff on emergency shutdown procedures ensures a rapid and coordinated response in the event of a UV-C system malfunction or accidental exposure incident. These procedures help mitigate the impact of any unforeseen issues and maintain a safe working environment.

E. Integration with Existing Clean Room Systems

HVAC System Compatibility

Coordinating the installation of UV-C lighting with the facility’s heating, ventilation, and air conditioning (HVAC) systems is crucial for maintaining a controlled environment and ensuring effective disinfection. Key considerations include:

Airflow Management: Integrating UV-C lamps within AHUs ensures that recirculating air is continuously disinfected, reducing the microbial load in the clean room. Proper airflow management enhances the overall effectiveness of UV-C disinfection by targeting airborne pathogens.

System Calibration: Ensuring that UV-C lighting systems are calibrated in tandem with HVAC systems maintains consistent environmental conditions and prevents disruptions in clean room operations. Calibration involves aligning UV-C intensity and airflow rates to achieve optimal disinfection without compromising clean room parameters.

Automation and Control Systems

Linking UV-C lighting with automated clean room controls facilitates synchronized operations and enhances overall system efficiency. Key integration practices include:

Centralized Control Platforms: Integrating UV-C systems with centralized control platforms, such as Supervisory Control and Data Acquisition (SCADA) systems, allows for real-time monitoring and management of disinfection processes. This integration enables automated adjustments to UV-C intensity and exposure times based on environmental conditions and operational demands.

Programmable Schedules: Implementing programmable schedules for UV-C lighting ensures that disinfection occurs at optimal times, such as during non-production hours or specific cleaning cycles. Automated scheduling reduces the need for manual intervention and ensures consistent disinfection practices.

Data Integration: Combining UV-C performance data with other clean room monitoring systems provides a holistic view of environmental conditions and sanitation efficacy. Data integration supports informed decision-making and continuous improvement of disinfection protocols.

F. Training and Standard Operating Procedures (SOPs)

Comprehensive Training Programs

Educating staff on the proper use, maintenance, and safety aspects of UV-C systems is essential for maximizing their effectiveness and ensuring workplace safety. Key elements of training programs include:

Operational Training: Training staff on the correct operation of UV-C systems, including turning lamps on and off, adjusting settings, and performing routine tasks ensures that systems are used effectively and safely.

Maintenance Training: Providing maintenance personnel with specialized training on cleaning, replacing components, and troubleshooting UV-C systems

ensures that maintenance tasks are performed correctly and efficiently, prolonging the lifespan of the equipment.

Safety Training: Educating workers on the hazards associated with UV-C exposure and the importance of adhering to safety protocols minimizes the risk of accidental exposure. Safety training should include the proper use of PPE, emergency procedures, and the importance of reporting any safety incidents promptly.

Developing Standard Operating Procedures (SOPs)

Creating detailed SOPs for UV-C system operation, maintenance, and emergency responses ensures consistency and reliability in sanitation practices. Key components of SOP development include:

Operational Guidelines: SOPs should provide step-by-step instructions for operating UV-C systems, including startup and shutdown procedures, adjusting settings for different disinfection needs, and integrating UV-C lighting with other clean room activities.

Maintenance Procedures: Detailed maintenance procedures outline the tasks required to keep UV-C systems functioning optimally, such as cleaning lamps, replacing filters and bulbs, and performing routine inspections. These procedures help standardize maintenance activities and prevent oversight.

Emergency Response Plans: SOPs should include clear protocols for responding to UV-C system malfunctions, accidental exposures, and other emergencies. These plans ensure that staff know how to act quickly and effectively to mitigate any potential hazards.

Documentation Practices: Establishing protocols for documenting all UV-C system activities, including maintenance logs, performance monitoring data, and incident reports, supports traceability and accountability. Proper documentation is essential for regulatory compliance and continuous improvement efforts.

V. Challenges and Considerations

While ultraviolet-C (UV-C) lighting offers numerous benefits for enhancing sanitation and contamination control in food production clean rooms, its implementation is not without challenges. Addressing these challenges is crucial to ensure the effective and safe utilization of UV-C technology. This section explores the key challenges and considerations associated with UV-C lighting, including material compatibility, ensuring uniform coverage, safety and health risks, and the financial implications of initial investment and return on investment (ROI).

A. Material Compatibility and Potential Damage

UV-C Effects on Materials

Prolonged exposure to UV-C light can have detrimental effects on various materials commonly found in clean rooms, including plastics, textiles, and certain types of coatings. UV-C radiation is highly energetic and can break down chemical bonds within materials, leading to degradation over time. For instance, plastics such as polycarbonate and acrylic may become brittle, discolored, or lose their structural integrity when exposed to continuous UV-C light. Textiles used in clean room garments can experience fiber weakening and loss of elasticity, compromising their protective capabilities. Additionally, adhesives and sealants may degrade, resulting in compromised seals and potential contamination ingress.

Selecting UV-Resistant Materials

To mitigate the adverse effects of UV-C exposure, it is essential to select materials that are inherently resistant to UV-C radiation. UV-resistant plastics, such as certain grades of polypropylene and polyethylene, offer enhanced durability and maintain their physical properties despite prolonged UV-C exposure. For textiles, materials treated with UV stabilizers or inherently UV-resistant fibers should be chosen to ensure longevity and maintain protective functions. Moreover, sealants and adhesives specifically formulated to withstand UV-C exposure should be utilized to maintain airtight and contamination-proof seals. By carefully selecting UV-resistant materials, food production facilities can preserve the integrity and functionality of their clean room components, ensuring sustained contamination control and operational efficiency.

B. Ensuring Uniform Coverage

Airflow Dynamics

Achieving uniform UV-C exposure within a clean room is critical for effective disinfection. Complex airflow patterns can create areas of stagnation or turbulence, leading to inconsistent UV-C exposure and potential microbial hotspots. Understanding the dynamics of airflow within the clean room is essential for optimizing UV-C lamp placement and ensuring that all areas receive adequate disinfection. Computational Fluid Dynamics (CFD) simulations can be employed to model airflow patterns and identify optimal locations for UV-C fixtures. Additionally, balancing the HVAC (heating, ventilation, and air conditioning) system to promote steady and laminar airflow can enhance the uniformity of UV-C exposure, ensuring comprehensive contamination control across the entire clean room environment.

Fixture Design

The design of UV-C fixtures plays a pivotal role in maximizing coverage and minimizing shadowed areas where contaminants might persist. Fixtures should be strategically positioned to ensure that UV-C light reaches all surfaces and airflows within the clean room. Adjustable fixtures that allow for tilting and angling can help direct UV-C rays more effectively, reducing the likelihood of shadowed zones. Incorporating reflective surfaces and utilizing multiple lamp configurations can further enhance light distribution, ensuring that hard-to-reach areas receive sufficient UV-C exposure. Additionally, modular and scalable fixture designs enable easy adjustments and expansions as clean room layouts evolve, maintaining optimal disinfection efficacy over time.

C. UV-C Light Safety and Health Risks

Health Hazards

Despite its effectiveness in microbial inactivation, UV-C light poses significant health risks if proper safety measures are not implemented. Direct exposure to UV-C radiation can cause severe skin burns, known as erythema, and eye injuries, including photokeratitis and cataracts. These health hazards necessitate stringent safety protocols to protect workers from accidental UV-C exposure. The high energy of UV-C photons makes them particularly hazardous, as even brief exposure can result in immediate and long-term health consequences.

Mitigation Strategies

To safeguard workers, comprehensive protective measures and safety protocols must be established when implementing UV-C lighting in clean rooms. Key strategies include:

Protective Equipment (PPE): Workers should be equipped with UV-resistant gloves, face shields, and protective eyewear to prevent direct exposure during maintenance and operation of UV-C systems.

Physical Barriers: Installing enclosed fixtures, UV-C shielding, and interlock systems that automatically shut off UV-C lamps when clean room doors are opened can prevent accidental exposure.

Warning Signage: Clearly visible signs indicating the presence of UV-C lighting and the associated hazards should be placed throughout the clean room to alert workers to potential risks.

Training Programs: Comprehensive training on the safe use and maintenance of UV-C systems is essential. Workers should be educated on the dangers of UV-C exposure, proper handling procedures, and emergency response actions in case of accidental exposure.

Automated Shut-Off Systems: Implementing sensors and automated controls that detect human presence and deactivate UV-C lamps can further reduce the risk of accidental exposure.

D. Initial Investment and ROI

Cost Considerations

The initial investment required for implementing UV-C lighting systems in food production clean rooms can be substantial. Costs include purchasing UV-C lamps and fixtures, integrating them with existing HVAC and automation systems, and conducting installation and validation procedures. Additionally, ongoing maintenance and component replacement add to the overall financial commitment. For many food manufacturers, especially small to medium-sized enterprises, these upfront costs can be a significant barrier to adoption.

Return on Investment

Despite the high initial costs, UV-C lighting offers substantial long-term cost savings that can offset the initial investment. Key factors contributing to a favorable ROI include:

Reduced Chemical Usage: UV-C disinfection reduces the reliance on chemical disinfectants, leading to savings on purchasing and disposal costs. This also minimizes environmental impact and compliance costs associated with chemical handling.

Lower Contamination Rates: Effective microbial control reduces the likelihood of contamination incidents, product recalls, and associated financial losses. By maintaining higher hygiene standards, UV-C lighting helps protect the manufacturer’s reputation and consumer trust, translating into sustained revenue and market competitiveness.

Extended Equipment Lifespan: By minimizing microbial-induced corrosion and wear, UV-C lighting can extend the lifespan of clean room equipment and surfaces, reducing the frequency of repairs and replacements.

Enhanced Product Shelf Life: Preventing spoilage and extending the shelf life of perishable goods can lead to increased sales and reduced waste, further enhancing profitability.

Energy Efficiency: Modern UV-C lighting systems, particularly LED-based solutions, are energy-efficient, resulting in lower operational costs over time.

In conclusion, while the initial investment in UV-C lighting systems can be significant, the long-term benefits in terms of cost savings, enhanced food safety, and operational efficiency provide a compelling case for their adoption in food production clean rooms.

VI. Future Trends and Innovations

As the food production industry continues to evolve, so does the technology that supports its stringent sanitation and safety requirements. Ultraviolet-C (UV-C) lighting, already a cornerstone in contamination control within clean rooms, is poised for significant advancements and integrations that will further enhance its efficacy and utility. This section explores the emerging trends and innovations in UV-C technology, focusing on advancements in lamp efficiency, smart systems and automation, sustainability, enhanced safety features, and integration with other disinfection methods.

A. Advancements in UV-C Technology

Improved Lamp Efficiency

The efficiency of UV-C lamps has seen remarkable improvements in recent years, driven by advancements in materials science and engineering. Traditional mercury-based UV-C lamps are being supplemented and, in some cases, replaced by more efficient alternatives such as LED-based UV-C lamps. These new technologies offer higher germicidal efficacy while consuming less energy, making them more sustainable and cost-effective in the long run. Enhanced lamp efficiency means that UV-C systems can achieve the same or greater disinfection levels with reduced power consumption, aligning with the growing demand for energy-efficient solutions in the food production sector.

Durable and Long-Lasting Components

Innovations in UV-C lamp components are also contributing to the longevity and reliability of UV-C systems. Advances in lamp design, such as the use of high-quality materials and improved manufacturing processes, have resulted in lamps that withstand prolonged exposure to UV-C radiation without significant degradation. Additionally, the development of protective coatings and enclosures helps prevent wear and tear, extending the lifespan of UV-C lamps and reducing the frequency of replacements. These durable components not only enhance the operational stability of UV-C systems but also lower maintenance costs and downtime, ensuring continuous and effective disinfection in clean rooms.

B. Smart UV-C Systems and Automation

Integration with IoT

The integration of Internet of Things (IoT) devices with UV-C systems is revolutionizing how disinfection processes are monitored and controlled. IoT-enabled UV-C systems can collect real-time data on various operational parameters, such as UV-C intensity, exposure duration, and environmental conditions like temperature and humidity. This data is transmitted to centralized platforms, allowing for remote monitoring and management of UV-C systems. The ability to access and analyze real-time data facilitates proactive maintenance, immediate troubleshooting, and data-driven decision-making, thereby enhancing the overall efficiency and reliability of UV-C disinfection processes.

Automated Cleaning and Maintenance

Automation is another key trend transforming UV-C systems. Modern UV-C systems are increasingly equipped with features that allow for automated cleaning and maintenance. For example, self-cleaning mechanisms can periodically remove dust and debris from lamp surfaces, ensuring consistent UV-C output without manual intervention. Additionally, automated systems can adjust UV-C settings based on real-time environmental conditions, optimizing disinfection efficacy while conserving energy. These automated capabilities not only reduce the labor required for system upkeep but also ensure that UV-C systems operate at peak performance with minimal human error.

C. Sustainable UV-C Solutions

Energy-Efficient Designs

Sustainability is a driving force behind the latest innovations in UV-C technology. Energy-efficient designs aim to minimize the power consumption of UV-C systems without compromising their disinfection capabilities. This is achieved through the use of advanced materials, optimized lamp geometries, and intelligent control systems that adjust UV-C output based on demand. Energy-efficient UV-C systems contribute to reducing the overall carbon footprint of food production facilities, aligning with global sustainability goals and regulatory requirements aimed at promoting environmentally responsible manufacturing practices.

Eco-Friendly Materials

The adoption of eco-friendly materials in UV-C system components is another significant trend. Manufacturers are increasingly using recyclable and non-toxic materials to construct UV-C lamps, fixtures, and housings. These materials not only reduce the environmental impact of UV-C systems but also enhance their safety and durability. By prioritizing sustainability in material selection, UV-C technology becomes a more attractive option for food producers committed to green manufacturing practices and reducing their ecological footprint.

D. Enhanced Safety Features

Advanced Shielding Technologies

Ensuring the safety of workers is paramount when implementing UV-C lighting in clean rooms. Advanced shielding technologies are being developed to prevent accidental UV-C exposure, which can cause skin burns and eye injuries. These technologies include improved physical barriers, such as enclosed fixtures and UV-resistant coatings, as well as automated safety interlocks that deactivate UV-C lamps when doors are opened or when human presence is detected. Enhanced shielding ensures that UV-C radiation is contained within designated areas, protecting workers while maintaining effective disinfection.

Real-Time Exposure Monitoring

Real-time exposure monitoring is another critical innovation aimed at safeguarding worker health. UV-C systems are now being equipped with sensors that continuously measure UV-C radiation levels and detect any unintended exposure. These sensors provide immediate alerts to operators if UV-C levels exceed safe thresholds, enabling prompt corrective actions to mitigate risks. Integrating real-time monitoring with automated control systems ensures that UV-C disinfection can be managed safely and efficiently, minimizing the potential for harmful exposure incidents.

E. Integration with Other Disinfection Methods

Hybrid Systems

Combining UV-C with other disinfection technologies is an emerging trend that enhances overall contamination control. Hybrid systems that integrate UV-C with ozone treatment, antimicrobial coatings, or chemical disinfectants provide a multifaceted approach to sanitation. For instance, UV-C can be used in conjunction with ozone to achieve deeper penetration and more comprehensive microbial inactivation, addressing a broader spectrum of pathogens and contamination sources. These hybrid systems leverage the strengths of multiple disinfection methods, ensuring robust and versatile sanitation solutions for clean rooms.

Synergistic Effects

The synergy between UV-C and existing sanitation protocols amplifies the effectiveness of contamination control measures. When UV-C is integrated with physical cleaning methods, such as wiping and scrubbing, it ensures that residual microbes are inactivated, preventing recontamination and enhancing the overall cleanliness of the environment. Additionally, UV-C can complement automated cleaning systems by targeting microorganisms that may evade conventional cleaning techniques. Exploring these synergistic effects enables food manufacturers to develop comprehensive and resilient sanitation strategies that maintain the highest standards of hygiene and food safety.

tain the highest standards of hygiene and food safety.

VII. Conclusion

Ultraviolet-C (UV-C) lighting has undeniably transformed contamination control strategies within food production clean rooms, offering a myriad of benefits that enhance food safety, operational efficiency, and regulatory compliance. Recapping the key advantages, UV-C lighting significantly improves contamination control by effectively reducing microbial loads on both airborne particles and surfaces. This robust disinfection capability not only safeguards the integrity of food products but also ensures compliance with stringent food safety regulations set forth by authorities such as the FDA and USDA. Moreover, UV-C lighting supports regulatory compliance by providing consistent and reliable sanitation practices that are easily documented and validated, thereby facilitating traceability and accountability in food manufacturing processes.

The impact on operational efficiency is equally noteworthy. UV-C lighting systems are designed to be energy-efficient, often consuming less power than traditional lighting and disinfection methods while delivering superior disinfection results. This energy savings translates into lower operational costs over time, making UV-C an economically viable solution for food manufacturers. Additionally, the cost-effectiveness of UV-C lighting is further enhanced by its ability to reduce the reliance on chemical disinfectants, thereby lowering material costs and minimizing environmental impact. Workflow improvements are also realized through the integration of UV-C systems with automated controls and monitoring technologies, which streamline disinfection processes and reduce the need for manual intervention, ultimately boosting productivity and operational reliability.

The importance of best practices in implementing UV-C lighting cannot be overstated. Ensuring effective implementation requires meticulous attention to proper installation, strategic placement of UV-C fixtures, and adherence to maintenance schedules to maximize the benefits of UV-C disinfection. Proper installation and placement guarantee comprehensive coverage and eliminate shadowed areas where contaminants might persist, while regular maintenance ensures the longevity and consistent performance of UV-C systems. Furthermore, implementing robust safety protocols and providing comprehensive training for staff are essential for protecting workers from the potential hazards of UV-C exposure and ensuring the safe operation of UV-C equipment. Sustaining long-term benefits relies on ongoing validation and monitoring of UV-C systems to maintain their efficacy over time. Continuous staff training and adherence to Standard Operating Procedures (SOPs) play a pivotal role in sustaining the effectiveness of UV-C lighting, ensuring that disinfection processes remain reliable and compliant with evolving regulatory standards.

Looking ahead, the future outlook for UV-C lighting in food production clean rooms is promising, marked by advancements in technology and a commitment to continuous improvement. Evolving technologies such as UV-C LEDs are set to enhance the efficiency and versatility of UV-C systems, offering more precise control over disinfection processes while reducing energy consumption and environmental impact. Innovations in smart UV-C systems and automation will further integrate UV-C lighting with Internet of Things (IoT) devices, enabling real-time monitoring and adaptive control that optimize disinfection efficacy based on environmental conditions. Continuous improvement through ongoing research and development will drive the enhancement of UV-C applications, exploring new methodologies and hybrid systems that combine UV-C with other disinfection technologies for comprehensive contamination control.

In final thoughts, the adoption of UV-C lighting underscores a steadfast commitment to food safety. By leveraging the powerful disinfection capabilities of UV-C light, food manufacturing facilities can significantly enhance public health protection through superior food safety measures. The compelling benefits of UV-C lighting, coupled with the necessity of best practices in implementation and maintenance, present a strong case for its widespread adoption. Encouraging food manufacturing facilities to integrate UV-C lighting into their comprehensive contamination control strategies is imperative for advancing food safety standards, ensuring regulatory compliance, and fostering a safer and more efficient production environment. As the food industry continues to prioritize hygiene and safety, UV-C lighting stands out as an essential tool in the ongoing effort to produce safe, high-quality food products for consumers worldwide.

Hieu VCR