In the electronics production line, the SMT inspection area requires standard lighting to detect micro-defects, reduce errors and avoid eye strain. Therefore, specialized lighting for the SMT inspection area becomes a mandatory factor to ensure high accuracy, stability and color fidelity in each inspection operation.

- 1. Why does the SMT inspection area require specialized lighting?

- 2. Key criteria for choosing lights for SMT areas

- 3. Types of specialized lights for SMT inspection areas

- 4. Installation Notes for Lighting in SMT Areas

- 5. Recommended VCR Lights for SMT Inspection Areas

- 6. Frequently Asked Questions about SMT Inspection Lighting

- 7. Need SMT Lighting Consultation? Contact VCR

1. Why does the SMT inspection area require specialized lighting?

In electronic manufacturing lines, the SMT (Surface Mount Technology) inspection area plays a crucial role in detecting component defects, soldering issues, or gaps on printed circuit boards (PCBs). To ensure accuracy during inspection-especially when done visually-the quality of lighting in this area must meet strict standards.

The role of lighting in SMT inspection:

- Supports detection of micro defects: Issues like cold solder joints, incorrect components, or misaligned soldering can only be clearly observed under strong lighting with a high color rendering index (CRI).

- Speeds up inspection: Proper lighting helps technicians quickly distinguish component colors, labels, and markings-reducing handling time.

- Minimizes errors caused by eye fatigue: Working in poor lighting conditions causes eye strain, reduced focus, and increased error rates.

Risks of using conventional lighting:

- Color distortion: Low-CRI lights misrepresent true colors, leading to mistakes in component identification.

- Glare and shadows: Lights without anti-glare features create harsh spots and shadows that hinder visibility.

- Unstable lighting: Cheap lights often flicker at high frequencies, straining the eyes and reducing inspection quality.

Lighting requirements for SMT inspection areas:

|

Lighting Criteria |

Standard Requirement |

|

CRI (Color Rendering Index) |

≥ 90 - accurately reproduces component colors |

|

Color Temperature |

5000K-6500K - cool white for enhanced contrast |

|

Light Distribution |

Even, without hot spots or dark zones |

|

Anti-Glare |

Yes - ensures comfortable continuous observation |

|

Flicker-Free Lighting |

Yes - stable and comfortable for prolonged inspection |

Using specialized lighting not only enhances inspection accuracy but also improves product quality and reduces error rates in the SMT production process.

2. Key criteria for choosing lights for SMT areas

When selecting lighting for SMT inspection zones, companies should evaluate more than just wattage or appearance. The following technical factors have a direct impact on inspection quality and workplace safety:

|

Criteria |

Detailed Description |

|

Color Temperature |

5000K-6500K - cool white light enhances contrast, ideal for detailed PCB and component inspection. |

|

CRI (Color Rendering Index) |

Minimum CRI ≥ 90 - ensures true color rendering for accurate visual checks of component codes and labels. |

|

Anti-Glare Design |

Choose lights with diffusers, honeycomb grids, or frosted lenses to reduce glare and eye fatigue. |

|

EMC Compliance |

Must meet EMC (Electromagnetic Compatibility) standards to prevent interference with sensitive equipment like AOI machines or soldering systems. |

|

Easy to Clean - Cleanroom Compatible |

Opt for sealed, smooth-surface lights without gaps-easy to wipe down and compliant with ISO 14644-1 Class 7-8 cleanroom standards. |

Investing in high-spec lighting improves inspection efficiency, reduces human errors, and extends the operational lifespan of electronics in SMT environments.

See more: Choosing lights for clean rooms: What indicators should you pay attention to?

3. Types of specialized lights for SMT inspection areas

Depending on area size, inspection purpose, and cleanroom design requirements, businesses can select from several types of specialized SMT lights. Below are three commonly used models:

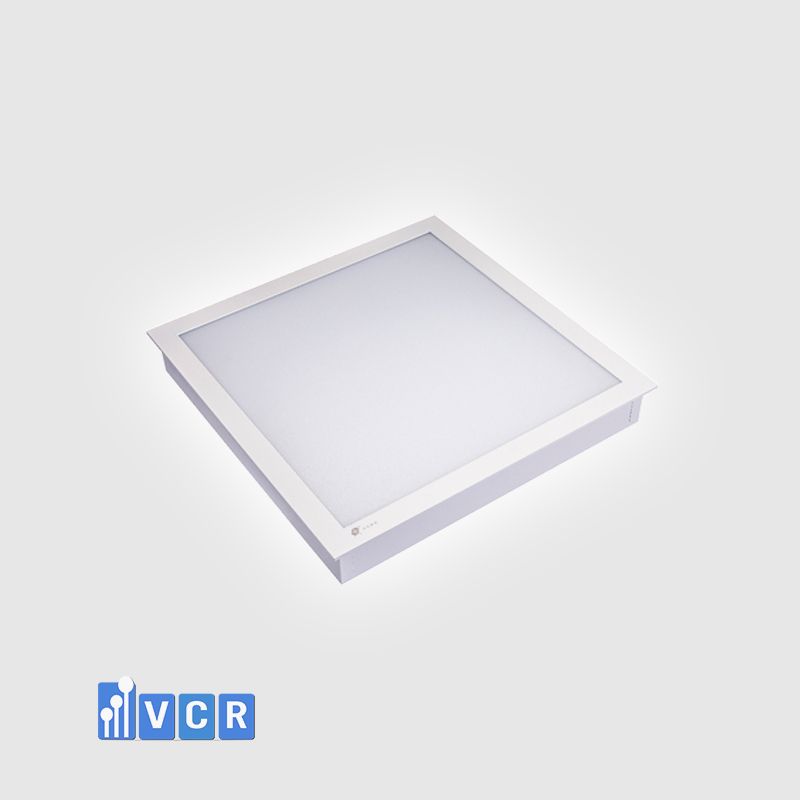

LED Panel Light (5000K-6500K)

- Slim design for ceiling mounting.

- Distributes light evenly with minimal shadows.

- Cleanroom-compatible with sealed, easy-to-clean surfaces.

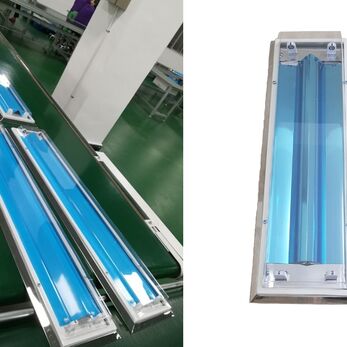

T8 Tube Light with Built-in Fixture (Anti-Glare)

- Compact and modular - suitable for narrow zones.

- Integrated design minimizes dust and reduces maintenance costs.

- Optional anti-glare features (e.g., frosted lens).

LED Light with Honeycomb Grid (Anti-Glare)

- Focused lighting with reduced glare thanks to honeycomb design.

- Ideal for visual inspection workstations requiring close-range observation.

Quick Comparison Table:

|

Light Type |

Key Advantages |

Best Application |

|

LED Panel |

Even light distribution, ceiling-mounted |

Wide inspection areas, high ceilings, central cleanrooms |

|

T8 Tube LED |

Flexible, easy to replace, cost-effective |

Narrow zones, test benches, technician workspaces |

|

Honeycomb Grid |

Effective glare reduction, focused lighting |

Small component inspection, close-up tasks |

By combining the right lights according to inspection function and location, manufacturers can optimize lighting efficiency while meeting ESD, cleanroom, and occupational safety standards in electronics production.

4. Installation Notes for Lighting in SMT Areas

Choosing the right type of light is not enough-how the lighting system is installed and arranged also significantly affects inspection efficiency and safety in SMT environments. Here are some key technical considerations:

1. Proper spacing to avoid shadows

Lights should be installed parallel to the working direction and distributed evenly on the ceiling to eliminate dark zones.

The spacing between fixtures should be calculated based on required illuminance (~500-750 lux for inspection areas).

Avoid placing lights directly behind technicians to prevent casting shadows over PCBs during handling.

2. Use reflective ceilings to enhance lighting efficiency

Ceilings painted white or coated with reflective materials help increase light dispersion and reduce energy consumption.

Additional light-colored wall panels or reflective side panels can be used to improve uniformity.

3. Prefer sealed fixtures - dustproof and insect-proof

Choose sealed lighting fixtures or integrated LED tubes to prevent dust and insects from entering, maintaining cleanliness in production areas.

This is especially crucial for ISO 7-8 cleanroom environments in electronics manufacturing, where strict control over particulates and microorganisms is required.

When installed correctly, a lighting system not only improves SMT inspection performance but also helps maintain cleanroom standards, reduce maintenance costs, and extend the service life of equipment.

See more: Mandatory lighting standards for Cleanroom Lights for QC areas

5. Recommended VCR Lights for SMT Inspection Areas

Based on the lighting requirements for SMT inspection-CRI, color temperature, cleanroom compliance, and EMC standards-VCR offers two specialized lighting models widely used in electronics factories:

Product Code: LED-VCR-SMT01

- Type: Recessed LED Panel

- Power: 36W

- CRI: 95 - ensures accurate color rendering for precise component inspection

- Color Temperature: 6000K - cool white light

- Protection Rating: IP65 - dustproof, insect-proof, suitable for cleanrooms

- Application: Large inspection areas, high ceilings, uniform lighting needed

Product Code: T8-EMC-600mm

- Type: Integrated LED Tube

- Length: 600mm - ideal for use at inspection tables

- Light Output: 6000K, flicker-free

- Certification: EMC-compliant - electromagnetic interference protection for sensitive electronic equipment

- Application: PCB inspection benches, close-up manual work areas

In addition to these two models, VCR provides various lighting options tailored to room size, cleanroom classifications, and specific technical requirements.

6. Frequently Asked Questions about SMT Inspection Lighting

Can regular lighting be used for SMT inspection areas?

No. Household-grade lights typically have low CRI, unstable output, and lack EMC certification. This can lead to color distortion, eye strain, and interference with sensitive electronics in the factory.

Is LED Panel lighting bright enough for PCB inspection?

Yes, provided that the panel light has a CRI ≥ 90 and a color temperature of 5000K-6500K. Proper fixture placement (to avoid shadows and ensure uniformity) is also essential for optimal visibility.

What CRI is recommended for SMT inspection lighting?

A CRI of 90 or above is recommended. This level of color rendering ensures true visual identification of components and minimizes errors during inspection of labels, markings, or solder joints.

7. Need SMT Lighting Consultation? Contact VCR

Lighting selection and layout for SMT areas is not just about brightness-it directly affects inspection quality, product accuracy, and compliance with cleanroom standards in electronics factories.

You should contact us if you're:

- Designing a new SMT plant and need early-stage lighting planning

- Upgrading your current lighting system to reduce inspection errors

- Looking for lighting solutions that meet EMC, CRI ≥ 90, and IP65 cleanroom standards

VCR’s technical team can support you with:

- Free on-site surveys

- Expert lighting configuration for each inspection zone

- Supply of certified, high-performance lighting for SMT and cleanroom environments

Hotline: 090.123.9008

Email: [email protected]

Website: https://denphongsach.com/

Diep VCR