Selecting luminaires for cleanrooms requires careful consideration of parameters such as Lux, CRI, IP Rating, UGR, anti-static properties and lamp housing materials. These are the factors that determine the ability to provide safe, stable lighting and compliance with ISO 14644 or GMP cleanroom standards in pharmaceuticals, cosmetics and food.

- 1. Quick summary table: Key technical indicators to consider when selecting cleanroom lighting

- 2. Why conventional lights cannot be used in sterile cleanrooms

- 3. Detailed explanation of key technical indicators for cleanroom lighting

- 4. Recommended lighting types by industry

- 5. How to verify whether lighting meets cleanroom standards

- 6. Frequently Asked Questionsabout cleanroom lighting

- 7. Contact us today to select the right lighting for your cleanroom

1. Quick summary table: Key technical indicators to consider when selecting cleanroom lighting

In cleanroom environments-especially sterile zones such as pharmaceutical weighing rooms, cosmetic filling areas, electronics production lines, or food packaging areas-lighting selection cannot be arbitrary. Below is a summary table of the most important technical indicators to consider when choosing lighting for sterile cleanrooms:

|

Technical Indicator |

Meaning |

Recommended Level |

|

Lux (Illuminance) |

Amount of light reaching the working surface, affecting visibility and detail recognition |

≥ 500 Lux (≥ 1000 Lux for critical work areas) |

|

CRI (Color Rendering Index) |

Color accuracy of the light source, critical for inspection and quality control |

CRI ≥ 80 (ideally ≥ 90) |

|

IP Rating |

Protection level against dust and water based on international standards |

IP65 or higher (IP66 for high-humidity areas) |

|

UGR (Unified Glare Rating) |

Anti-glare performance affecting visual comfort and worker health |

UGR < 19 |

|

Anti-static |

Prevents electrostatic discharge that may damage electronics or ignite sensitive materials |

Mandatory for electronics and sensitive pharmaceutical areas |

|

Housing Material |

Durability, cleanability, and compatibility with cleanroom environments |

Powder-coated aluminum or antibacterial polycarbonate (PC) |

These technical indicators serve as the foundation to help you filter and select lighting solutions suitable for ISO 14644 or GMP standards across different industries.

2. Why conventional lights cannot be used in sterile cleanrooms

Although all lighting fixtures serve the purpose of illumination, standard residential or industrial lights are not suitable for cleanroom environments. Using the wrong type of light can negatively impact production, inspection processes, and final product quality. Here are the specific reasons:

1. Failure to meet ISO cleanliness requirements

- Conventional lights have gaps, seams, and textured surfaces that trap dust and microorganisms.

- They lack airtight construction, disrupting clean airflow patterns.

- Difficult to sanitize properly, risking non-compliance with ISO 14644-1 or GMP.

2. Electrostatic discharge (ESD) risks

- Many standard lights use non-ESD-safe plastic housings.

- Static charges can damage electronic components in SMT and semiconductor processes.

- In pharmaceutical environments, static may attract dust or interfere with lab testing.

3. Inadequate lighting performance

- Many lights cannot achieve ≥ 500 Lux or have CRI < 80, degrading inspection accuracy.

- Flickering or uneven lighting leads to visual fatigue and lowers worker productivity.

4. Audit and compliance issues

- Improper lighting design often results in GMP or ISO audit failures.

- Fixtures with gaps, dust accumulation, or missing IP/CRI certification may cause supplier disqualification.

See more: Cleanroom LED panel lights: How to choose lux for each cleanliness level

3. Detailed explanation of key technical indicators for cleanroom lighting

Lighting in sterile cleanrooms must meet specific technical standards beyond simple brightness. Below are the five essential indicators you should always consider:

a. Lux (Illuminance)

Lux measures the amount of light that reaches a surface. Different cleanroom areas require different illuminance levels based on the task:

|

Area |

Recommended Lux Level |

|

Hallways, airlocks |

200-300 Lux |

|

Preparation areas |

300-500 Lux |

|

Filling/Mixing zones |

≥ 1000 Lux |

|

QC laboratories, analytical rooms |

≥ 750 Lux |

Insufficient illuminance reduces accuracy during critical operations and increases the risk of production errors.

b. CRI (Color Rendering Index)

CRI measures how accurately a light source reproduces colors.

- CRI ≥ 80: Minimum for general cleanroom tasks.

- CRI ≥ 90: Recommended for quality control, color inspection, and foreign-particle detection.

Applications: Ideal for cosmetics, pharmaceuticals, and food industries where color accuracy is critical.

c. IP Rating (Dust/Water Protection)

The IP rating indicates how well a fixture is protected from dust and water ingress.

- General cleanrooms: IP65 or higher

- High-humidity or washdown areas: IP66/IP67

IP65 ensures complete dust protection and resistance against low-pressure water jets, suitable for sterile environments.

d. UGR (Unified Glare Rating)

UGR evaluates the level of glare produced by lighting.

- UGR < 19: Optimal for long-term work environments

- Applications: Continuous production areas, inspection workstations

High UGR leads to visual discomfort, fatigue, and reduced productivity.

e. Anti-static (ESD protection)

Static electricity poses serious risks in:

- Electronics manufacturing: Can destroy sensitive components

- Pharmaceuticals: May create sparks near solvents or powders

- High-grade cleanrooms: Attracts particles and compromises cleanliness

Solution: Use ESD-safe lighting with materials that dissipate static charge effectively.

4. Recommended lighting types by industry

Each cleanroom industry has unique requirements for lighting related to cleanliness, humidity, safety, and inspection needs. Below are recommended lighting types for each field, along with important technical considerations:

Pharmaceutical Industry (GMP - EU/WHO)

- Recommended lights: LED panel with sealed housing, IP65+, CRI ≥ 80

- Notes:

- Fully sealed structure to prevent particle leakage

- Smooth surface for easy disinfection

- Stable, flicker‑free lighting for weighing and compounding rooms

Food Industry (HACCP, ISO 22000)

- Recommended lights: LED IP66, moisture‑resistant

- Notes:

- High‑humidity environments require waterproof fixtures

- Use polycarbonate or antibacterial diffusers approved for food zones

- Low heat emission to protect temperature‑sensitive products

Cosmetics Industry (ISO 22716)

- Recommended lights: Natural white LED (4000-5000K), high CRI (≥ 90)

- Notes:

- Ensures accurate color identification to detect contamination or defects

- Low‑glare design preferred for prolonged visual tasks

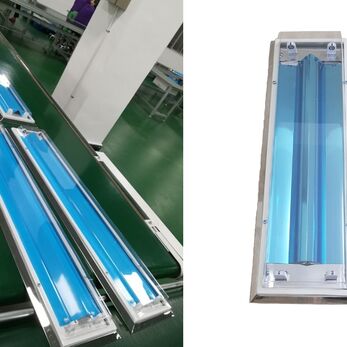

Electronics - SMT - Semiconductor

- Recommended lights: Anti-static, UV‑free lighting

- Notes:

- Avoid fixtures generating ozone or UV radiation

- ESD certification required

- Diffused lighting reduces reflection on circuit surfaces

Healthcare - Clinics - Operating Theatres

- Recommended lights: Antibacterial LED, 4000-5000K

- Notes:

- Minimal heat generation for surgical rooms

- Antimicrobial coating for easy sterilization

- Adjustable brightness (dimming) for specific procedures

5. How to verify whether lighting meets cleanroom standards

Just because a product is labeled “cleanroom-compatible” doesn’t mean it truly meets ISO or GMP standards. To ensure lighting fixtures are genuinely suitable for sterile environments, follow a clear and objective verification process before installation.

1. Request CO and CQ from the manufacturer

- CO (Certificate of Origin): Verifies the country of origin.

- CQ (Certificate of Quality): Confirms product quality, typically includes technical specifications.

Note: Be cautious if the CO/CQ is unclear, manually printed, or lacks traceability codes, as this may affect the product’s reliability.

2. Verify product certifications

Some certifications are mandatory or strongly recommended for cleanroom lighting:

|

Certification |

Description |

|

ISO 9001 |

Quality management in manufacturing |

|

CE |

Compliance with European safety standards |

|

RoHS |

Free from hazardous substances such as lead or mercury |

|

ESD/Antistatic |

Electrostatic discharge protection - required in electronics manufacturing |

Note: Prioritize suppliers certified by globally recognized bodies like SGS, TUV, or UL.

3. On-site measurement and validation

Before commissioning or operation:

- Use a lux meter to measure illuminance at working zones and ensure it meets the design criteria.

- Use professional instruments to check:

- CRI (Color Rendering Index)

- UGR (Unified Glare Rating)

- Color temperature (Kelvin)

Measurements should align with the actual environmental requirements and match declared specifications.

4. Evaluate design and materials

Physically inspect the light fixture for the following:

- Smooth, gap-free surfaces that are easy to clean and resist dust accumulation.

- Durable gaskets that ensure airtight sealing and prevent particle ingress (≥ IP65).

- Housing materials:

- Powder-coated aluminum (durable, corrosion-resistant)

- Antibacterial polycarbonate (for food and healthcare sectors)

See more: Choosing the Best Cleanroom Lights for Your Factory

6. Frequently Asked Questionsabout cleanroom lighting

Can standard LED lights be used in cleanrooms?

No. Consumer-grade LEDs often lack sealed construction, suitable materials, and cleanability. They accumulate dust, are hard to disinfect, may generate static electricity, and fail to deliver uniform illuminance-leading to cross-contamination and operational errors in sterile areas.

What CRI is sufficient for the pharmaceutical industry?

CRI ≥ 80 is the minimum standard. For color inspection areas (QA/QC), capsule identification, or impurity detection, CRI ≥ 90 is preferred to ensure color fidelity and accuracy.

Is anti-static lighting necessary in cleanrooms?

Yes-mandatory for electronics, semiconductors, and SMT lines, where static discharge can damage components. In pharmaceuticals, anti-static lights are strongly recommended to reduce spark risk in alcohol, solvent, or powder-handling zones.

Should cleanroom lights be antibacterial?

They should be-especially in food, cosmetics, and healthcare environments where microbial growth is a concern. Antibacterial LED lights often feature silver-ion coatings, antimicrobial PC materials, or sealed designs that prevent contamination and allow easy cleaning with alcohol or disinfectants.

7. Contact us today to select the right lighting for your cleanroom

Choosing lighting for cleanrooms is not simply about brightness-it’s about compliance with technical standards, ISO/GMP regulations, durability, and biosafety.

If you are:

- Building or upgrading a cleanroom for pharmaceuticals, food, electronics, or cosmetics

- Unsure which lighting fits your cleanroom class, audit standards, or illumination needs

- Seeking transparent consultation and quotations from industry experts

Let VCR assist you!

What VCR offers:

- Free consultation based on industry and cleanroom classification

- Products with complete CO, CQ, CE, ISO, and RoHS certifications

- Fast delivery - professional installation - expert technical support

Hotline: 090.123.9008

Email: [email protected]

Website: https://denphongsach.com/

Diep VCR