Cleanroom lighting is not just a lighting device, but also a factor that directly affects the production environment quality according to GMP and ISO 14644 standards. This article compiles the questions engineers frequently encounter when selecting, installing, and maintaining cleanroom lighting – together with detailed answers from VCR experts.

1. Purpose of the article

When deploying a lighting system for a cleanroom environment – especially in industries such as pharmaceuticals, food, electronics, or cosmetics – engineers often face many questions about cleanroom lights such as installation, repair, and maintenance. Unlike ordinary household lights, cleanroom lights must meet many stringent requirements, including:

-

A sealed structure, dust-proof, bacteria-proof.

-

Compatibility with cleanroom ceilings.

-

Compliance with GMP, ISO 14644 or guidelines from FDA/EU.

-

High durability, stable lighting, easy to clean and replace.

This article is designed to collect the most common questions engineers encounter and to provide detailed answers across important technical aspects, helping to: -

Save time researching when launching a new project.

-

Have a clear technical basis to compare different lighting options.

-

Avoid common mistakes during the design or construction of the clean lighting system.

In addition, the information here helps the technical team or M&E department to proactively work with the supplier during quoting, choosing suitable models and performing periodic maintenance.

If you are involved in the design, construction or operation of a cleanroom – this will be a reliable reference to optimize selecting the right lighting, for the right standard and right needs.

Read more: Comparison of UV and LED lamps in clean rooms: Practical applications

2. Frequently asked questions about cleanroom lights (FAQ)

2.1. What is a cleanroom light? How is it different from regular lighting?

Cleanroom lights are specially designed for use in environments controlling dust, microbes and contaminants – typical in pharmaceutical, food, electronics or cosmetics factories. Unlike household lights, cleanroom lights have these features:

-

A sealed, dust-proof, watertight structure (IP54–IP65 or higher).

-

Antibacterial materials, easy to wipe clean (often stainless steel, powder-coated steel, PC plastic).

-

No gaps where dust can accumulate, no particle generation.

-

Design that ensures not to interrupt the clean airflow.

Cleanroom lights typically must comply with GMP and ISO 14644 standards, ensuring lighting safety without affecting the cleanliness level of the room.

2.2. What are the common types of cleanroom lights today?

Currently, engineers can choose from the following types of cleanroom lights depending on project requirements and ceiling type:

-

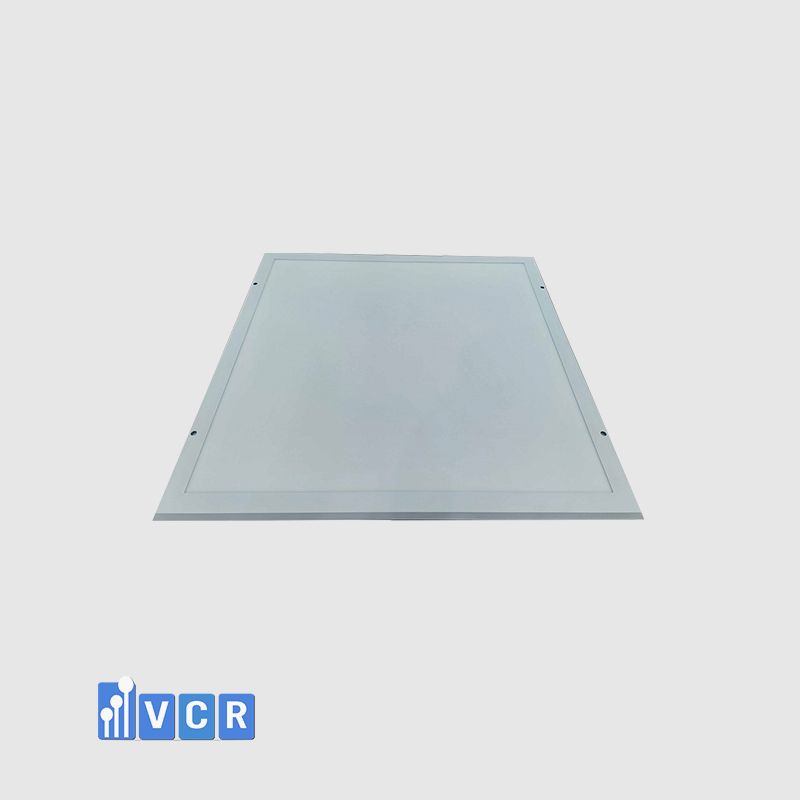

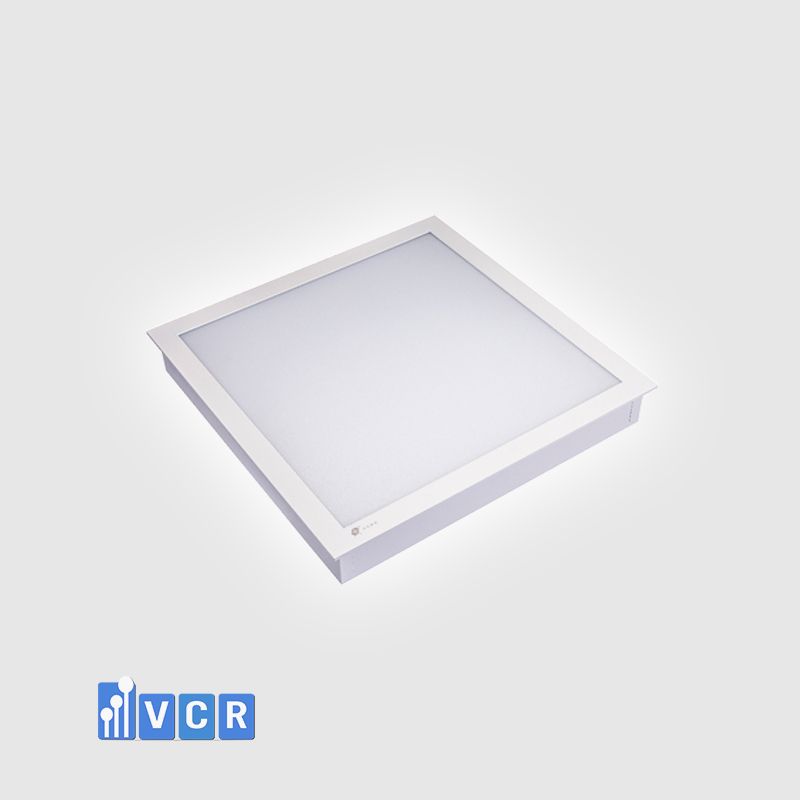

LED Panel lights recessed in ceiling: slim design, uniform light, easy to integrate with aluminum clean-room ceilings.

-

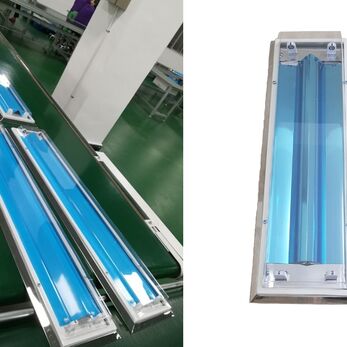

Dust-proof LED tube lights: long form, easy replacement, surface mount or wall mount, suitable for corridors or technical areas.

-

Explosion-proof lights: used in zones with risk of flammable gases, such as chemical rooms.

Read more: Provider of Cleanroom Lights Resistant to Mold and Dampness for the Food Industry

2.3. What IP rating do cleanroom lights usually have?

Standard cleanroom lights usually have protection ratings from IP54 to IP65, depending on the application area:

-

IP54: Limited dust protection, resistant to water spray from any direction – sufficient for basic clean areas.

-

IP65: Fully dust-proof and able to withstand light jet of water – suitable for high-cleanliness areas or those frequently sanitized.

“IP” stands for “Ingress Protection”, representing the device’s protection against dust and water – a very important factor in cleanroom environments.

2.4. What should engineers pay attention to when choosing lights for a cleanroom?

When selecting cleanroom lights, engineers should consider these factors:

-

Light color: Prefer neutral white light (4000K – 6500K), non-glare, no flicker.

-

Luminance: Suitable for the lighting standard of the area (lux), avoiding too dim or too bright.

-

Energy efficiency: Choose LED lights with suitable power and high efficiency.

-

Lifespan & reliability: At least 30,000 hours of use, reducing maintenance frequency.

-

Housing material: PC plastic resistant to UV, powder-coated steel, or stainless steel resistant to chemicals.

2.5. Are there any particular installation requirements for cleanroom lights?

Installing lights in a cleanroom must ensure:

-

Compatibility with the clean ceiling: aluminum ceiling, sealed gypsum ceiling, hard ceiling…

-

Recessed installation sealed tightly, avoiding gaps between the light and ceiling that allow dust infiltration.

-

Vibration-proof and easy maintenance: Use genuine accessories, arrange for convenient replacement.

Read more: Supplier of GMP‑Standard Cleanroom LED Panel Lights

2.6. Do cleanroom lights need certification?

Cleanroom lights meeting standard should have these certifications:

-

CRI (Color Rendering Index) ≥ 80, ensuring light quality

-

RoHS, CE: Environmental and health safety

-

ISO 9001 or equivalent

-

Lights should comply with lighting requirements under EU GMP, FDA (21 CFR 211.44) if used in pharmaceutical factories.

2.7. Lifespan and warranty of cleanroom lights?

-

LED cleanroom light lifespan: Typically from 30,000 – 50,000 hours.

-

Typical warranty: 12 – 24 months depending on manufacturer.

-

Choose lights with LM80, TM21 data proving long-term light stability.

2.8. How much do cleanroom lights cost?

Depending on type and technical specifications, cleanroom lights cost:

| Type of light | Reference price in VND |

|---|---|

| LED Panel light | 800,000 – 1,500,000 |

| Dust-proof LED tube light | 500,000 – 1,000,000 |

| Explosion-proof cleanroom light | From 2,000,000 or more |

Read more: Cleanroom Lighting Standards: Are They Mandatory?

2.9. Can regular domestic lights be used instead of cleanroom lights?

Not recommended. Using household lights in a cleanroom may cause:

-

Dust generation from gaps and non-compliant materials.

-

Poor air-tightness, affecting cleanliness level.

-

Unable to be cleaned with chemical disinfectants.

-

Short lifespan if not resistant to humidity or pressure.

2.10. Where to buy cleanroom lights from a reputable source?

When choosing a supplier for cleanroom lights, engineers should prioritise those that:

-

Have real-world experience in pharmaceutical, food, electronics industries.

-

Provide full product certification.

-

Provide technical consulting suited to each cleanliness class.

-

Have installation and maintenance support teams.

Read more: Cleanroom LED panel lights: How to choose lux for each cleanliness level

3. Quick comparison table: common types of cleanroom lights

The table below helps engineers and contractors quickly compare popular cleanroom light types by technical criteria, real-world applications, and reference prices:

| Type of light | Key advantages | Common application | Reference price (VND) |

|---|---|---|---|

| LED Panel light | Slim design, sealed, gentle light | Cleanrooms with drop ceiling | 800,000 – 1,500,000 |

| Dust-proof LED tube light | Surface mount, quick replacement, low power | Corridors, clean storage rooms | 500,000 – 1,000,000 |

| Explosion-proof cleanroom light | Safe in combustible environments | Chemical rooms, QC test rooms | From 2,000,000 or more |

Note: Prices are for reference only and may vary depending on power, IP rating, housing material, and brand. For detailed quotation and consulting for each project, please contact the VCR technical team.

Read more: UV-C Lighting in Food Production Clean Rooms: Benefits and Best Practices

If you are planning a cleanroom project and need lighting consulting to align with GMP, ISO 14644 standards, let the VCR technical team support you by:

-

Advising lighting selection for each clean area.

-

Supporting drawings, quotations and coordination in construction.

-

Supplying fully certified products – genuine import.

Contact:

Hotline: 090.123.9008

Email: [email protected]

Website: https://denphongsach.com/

Dat VCR