In the meticulously controlled environment of a cleanroom, maintaining pristine conditions is paramount. Every element, from construction materials to equipment, plays a crucial role in preventing contamination.

Consequently, cleanroom lighting transcends its traditional function of illumination, adhering to stringent cleanliness requirements. Okay now let us learn about preventative strategies for cleanroom lighting.

Beyond Cost Considerations

While cost analysis often reigns supreme in equipment selection, cleanroom lighting presents a nuanced picture. While initial and maintenance costs do factor into the decision-making process, it's essential to acknowledge the minimal impact of lighting on overall energy consumption. Studies reveal that lighting typically accounts for less than 1% of total cleanroom energy usage. Therefore, focusing solely on minimizing lighting expenditure might lead to suboptimal solutions that compromise contamination control.

Tailoring Light to Task

Optimal lighting in a cleanroom hinges on understanding the diverse activities undertaken within its walls. Illumination requirements vary significantly, from meticulous micro-manipulation to macro-scale assembly processes. Engaging a lighting design professional proves invaluable in determining the precise lux levels needed for each specific task, ensuring both accurate vision and minimal energy waste.

Airflow vs Illumination in Cleanroom

Cleanroom design presents unique challenges where efficient air handling systems sometimes clash with optimal lighting placement. For high-cleanliness environments, where meticulous airflow control reigns supreme, traditional ceiling-mounted fixtures might face spatial constraints. However, innovative solutions exist. Collaborating with experienced cleanroom designers can overcome these hurdles, resulting in lighting layouts that seamlessly integrate with existing air supply systems without compromising illumination or cleanliness.

Beyond Fluorescent: A Spectrum of Options

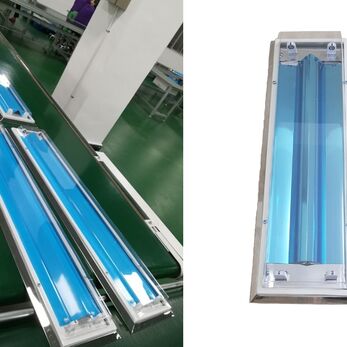

Fluorescent lamps have long dominated cleanroom lighting due to their energy efficiency, low maintenance, and extended lifespan. However, the lighting landscape is evolving. Recent advancements showcase the growing adoption of LED panel lights in cleanrooms. Their advantages are compelling: exceptional longevity, high efficacy, and minimal heat generation, contributing to a cooler, more comfortable working environment. Additionally, some light fixtures utilize ultraviolet radiation to achieve enhanced sanitation, further minimizing potential contamination risks.

See more: Factors Determining Cleanroom Lighting

Conclusion

Investing in effective cleanroom lighting extends beyond mere illumination. It's a critical element in maintaining the stringent purity levels demanded by these specialized environments. Understanding the interplay between cost, air supply, illumination needs, and emerging technologies empowers informed decision-making. By prioritizing cleanliness alongside efficiency, you can create a cleanroom that fosters both impeccable product quality and a safe, comfortable workspace for your team.

Note:

The promotional section about Vietnam Cleanroom Equipment has been removed as it is not directly related to the topic of cleanroom lighting and disrupts the flow of the article.

Read more: